A product with high resistant starch content prepared by ultra-high pressure synergistic enzymes and its preparation method

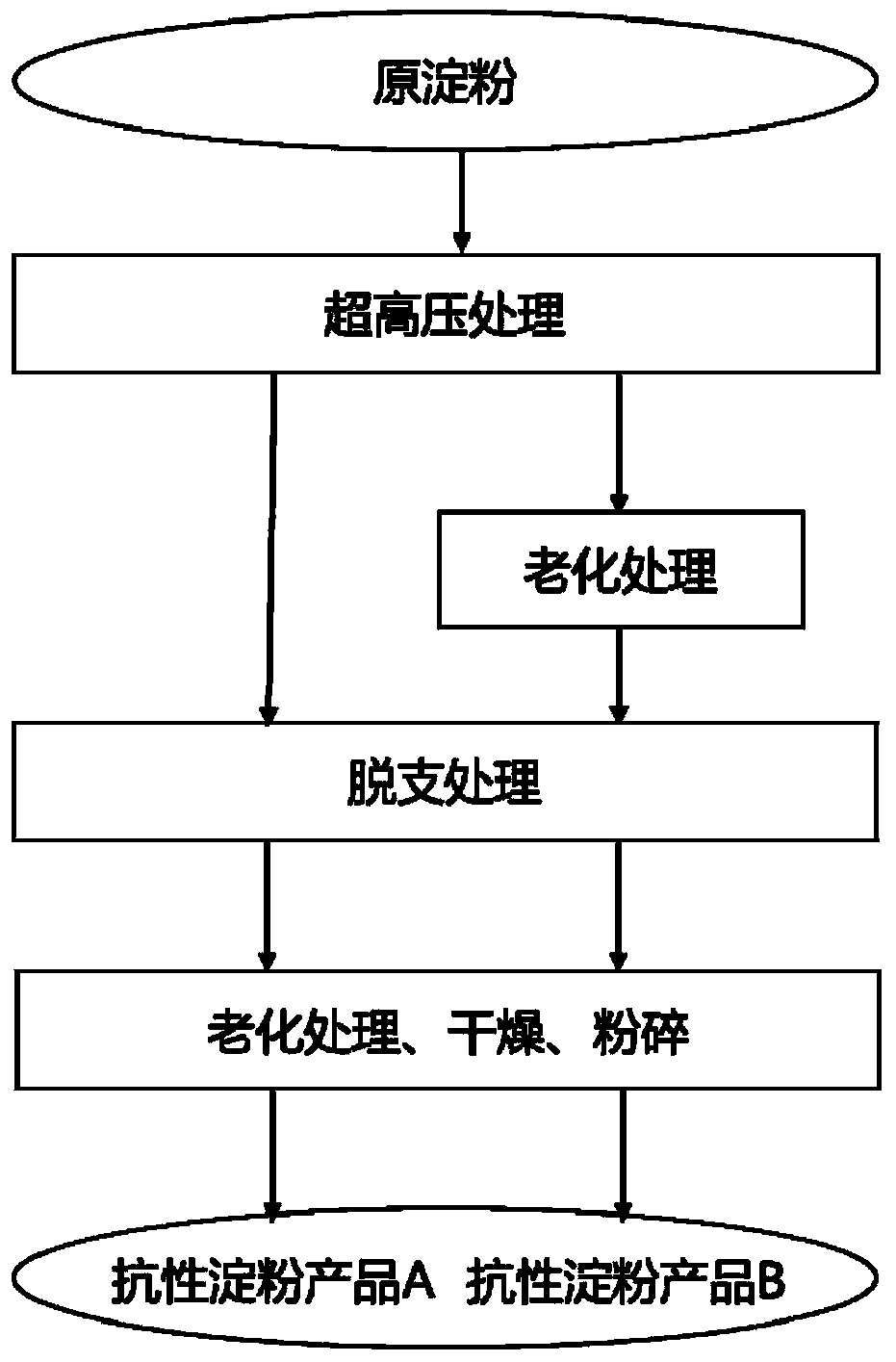

A high-resistant starch, ultra-high pressure technology, applied in the field of food processing, can solve the problems of yellowing of resistant starch products, complicated production process, affecting addition and application, etc., and achieves low cost, clean production process, and promotes unfolding and dissociation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Example 1: Preparation of Resistant Starch Product A - Method 1

[0093]1) Using sweet potato starch as a raw material, prepare a starch suspension with a concentration of 25% by weight with distilled water, seal the starch suspension with a polyethylene bag, and place it at 600 MPa at 25°C for 30 minutes of ultra-high pressure treatment to obtain a starch paste for subsequent use ;

[0094] 2) After cooling the starch paste to room temperature, adjust the pH of the starch paste to 6 with 2M hydrochloric acid, add pullulanase at 20 ASPU per g of starch, and then hydrolyze at 60°C for 12 hours;

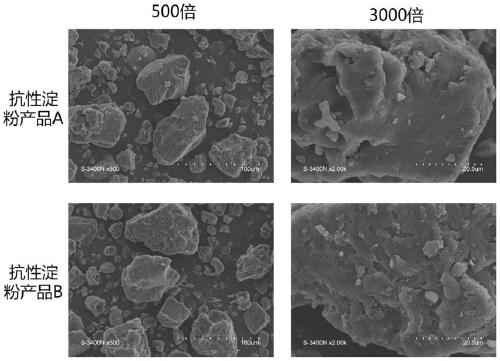

[0095] 3) Cool the hydrolyzed starch milk to room temperature, adjust the pH of the starch paste to 2 with 2M hydrochloric acid, let stand at room temperature for 1 hour to inactivate the enzyme, then age at 4°C for 24h, and then dry at 60°C for 48h , pulverized with a universal pulverizer, and passed through an 80-mesh standard sieve to obtain the resistant starch product A. ...

Embodiment 2

[0097] Example 2: Preparation of Resistant Starch Product A - Method 2

[0098] 1) Using sweet potato starch as a raw material, prepare a starch suspension with a concentration of 20 wt% with distilled water, seal the starch suspension with a polyethylene bag, place it at 600 MPa at 25°C for 20 minutes of ultra-high pressure treatment, and obtain a starch paste for future use ;

[0099] 2) After cooling the starch paste to room temperature, adjust the pH of the starch paste to 5.5 with 2M hydrochloric acid, add isoamylase at 22 ASPU per g of starch, and then hydrolyze at 60°C for 12 hours;

[0100] 3) Cool the hydrolyzed starch milk to room temperature, adjust the pH of the starch paste to 2 with 2M hydrochloric acid, let stand at room temperature for 1 hour to inactivate the enzyme, then age at 4°C for 24h, and then dry at 60°C for 48h , pulverized with a universal pulverizer, and passed through an 80-mesh standard sieve to obtain the resistant starch product A.

Embodiment 3

[0101] Example 3: Preparation of Resistant Starch Product A - Method 3

[0102] 1) Using cornstarch as raw material, prepare a starch suspension with a concentration of 25% by weight with distilled water, seal the starch suspension with a polyethylene bag, and place it at 600 MPa at 25°C for 30 minutes of ultra-high pressure treatment to obtain a starch paste for later use ;

[0103] 2) After cooling the starch paste, adjust the pH of the starch paste to 6 with 2M hydrochloric acid, add pullulanase at 20 ASPU per g of starch, and then hydrolyze at 60°C for 12 hours;

[0104] 3) Cool the hydrolyzed starch milk to room temperature, adjust the pH of the starch paste to 2 with 2M hydrochloric acid, let stand at room temperature for 1 hour to inactivate the enzyme, then age at 4°C for 24h, and then dry at 55°C for 48h , pulverized with a universal pulverizer, and passed through an 80-mesh standard sieve to obtain the resistant starch product A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com