High-temperature-resistant seamless steel pipe and preparation method thereof

A technology for seamless steel pipes and high temperature resistance, which is applied in the field of steel pipes and can solve the problems of complicated preparation process, poor high temperature resistance performance and mechanical strength of seamless steel pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

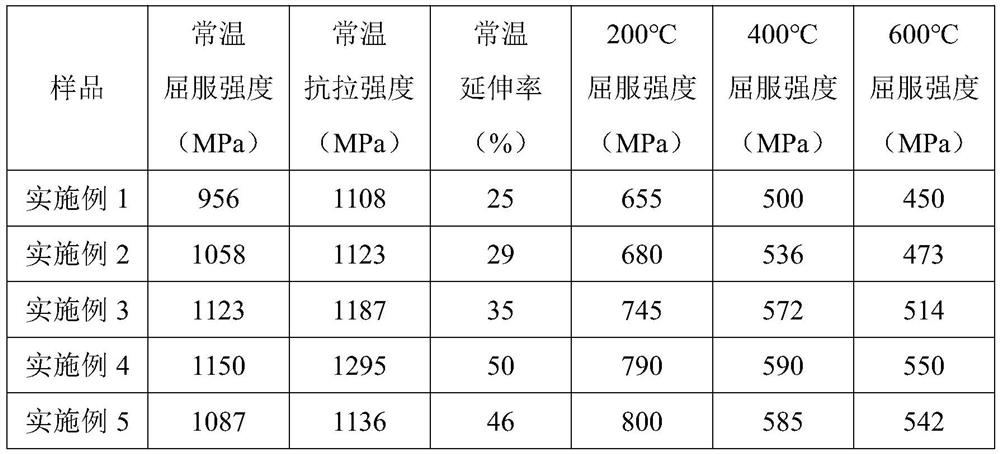

Examples

Embodiment 1

[0018] The chemical composition and mass percentage of the high temperature resistant seamless steel pipe provided in this example are:

[0019] C: 0.12%, Mn: 0.5%, Si: 0.5%, Cr: 8%, Ni: 22%, Ti: 0.05%, V: 0.02%, Cu: 0.05%, W: 0.18%, Pt: 0.005%, Mo: 0.05%, Os: 0.002%, Nb: 0.005%, Re: 0.005%, Zr: 0.005%, Ta: 0.015%, P: 0.02%, S: 0.005%, and the balance is Fe and unavoidable impurities.

[0020] The specific steps for preparing the above-mentioned high-temperature resistant seamless steel pipe are as follows:

[0021] (1) After the molten iron is pretreated, it is smelted in a converter, alloy components are added, and refining agent is added for refining outside the furnace, and argon is filled during the refining process; then it is vacuum degassed, the vacuum degree is ≤0.1Kpa, and the degassing time is 20 minutes; and then Carry out round tube billet continuous casting, cooling and annealing treatment.

[0022] (2) The obtained round billet is heated by a ring furnace and ...

Embodiment 2

[0025] The chemical composition and mass percentage of the high temperature resistant seamless steel pipe provided in this example are:

[0026] C: 0.15%, Mn: 0.5%, Si: 0.8%, Cr: 10%, Ni: 25%, Ti: 0.08%, V: 0.03%, Cu: 0.1%, W: 0.2%, Pt: 0.008%, Mo: 0.08%, Os: 0.006%, Nb: 0.01%, Re: 0.01%, Zr: 0.01%, Ta: 0.015%, P: 0.005%, S: 0.002%, and the balance is Fe and unavoidable impurities.

[0027] The specific steps for preparing the above-mentioned high-temperature resistant seamless steel pipe are as follows:

[0028] (1) After the molten iron is pretreated, it is smelted in a converter, alloy components are added, refining agent is added and refined outside the furnace, and argon is filled during the refining process; then it is vacuum degassed, the vacuum degree is ≤0.1Kpa, and the degassing time is 30 minutes; and then Carry out round tube billet continuous casting, cooling and annealing treatment.

[0029] (2) The obtained round billet is heated by a ring furnace and then pie...

Embodiment 3

[0032] The chemical composition and mass percentage of the high temperature resistant seamless steel pipe provided in this example are:

[0033] C: 0.18%, Mn: 0.6%, Si: 1%, Cr: 12%, Ni: 28%, Ti: 0.12%, V: 0.04%, Cu: 0.15%, W: 0.23%, Pt: 0.012%, Mo: 0.1%, Os: 0.01%, Nb: 0.02%, Re: 0.015%, Zr: 0.015%, Ta: 0.018%, P: 0.01%, S: 0.005%, and the balance is Fe and unavoidable impurities.

[0034] The specific steps for preparing the above-mentioned high-temperature resistant seamless steel pipe are as follows:

[0035] (1) After the molten iron is pretreated, it is smelted in a converter, alloy components are added, refining agent is added to refine it outside the furnace, and argon is filled during the refining process; then it is vacuum degassed, the vacuum degree is ≤0.1Kpa, and the degassing time is 40 minutes; Carry out round tube billet continuous casting, cooling and annealing treatment.

[0036] (2) The obtained round billet is heated by a ring furnace and then pierced to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com