A kind of copper-iron alloy wire rod and preparation method thereof

A copper-iron alloy and wire technology, which is applied in the field of copper-iron alloy wire preparation, can solve the problems of high casting and processing cost, long process, high temperature annealing and the like, and achieves the effects of reducing production cost, uniform composition and high machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

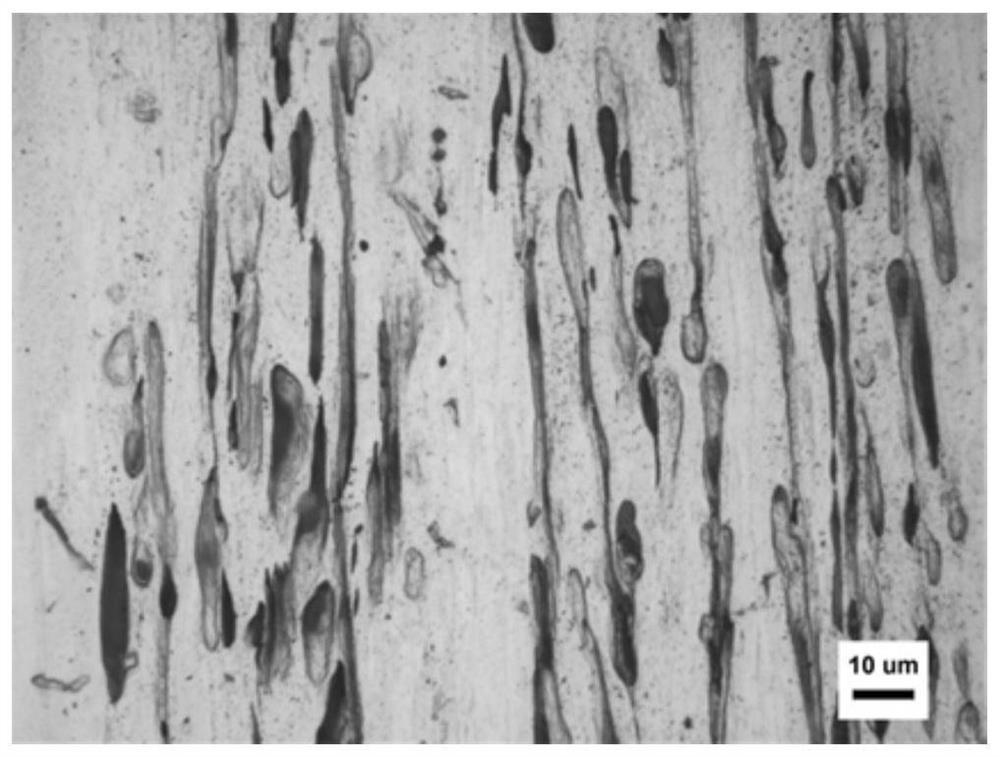

Image

Examples

Embodiment 1

[0047] Example 1 and Example 5 were prepared by the method of the present invention, and the specific ingredients are shown in Table 1.

[0048] Example 1: Preparation of a copper-iron alloy wire rod with a diameter of 2mm and iron content of 5.12%. The process flow of the copper-iron alloy wire rod is: batching → melting and casting → slag removal converter → impurity removal, degassing → horizontal continuous casting → cold rolling → Annealing→drawing, specifically:

[0049] 1) Ingredients: Weigh the electrolytic copper plate, copper-iron master alloy according to the composition, Fe in the copper-iron master alloy: 48-52wt%;

[0050] 2) Smelting: adding the electrolytic copper plate and the copper-iron intermediate alloy into the smelting furnace to heat up and melt in sequence;

[0051] 3) Slag removal converter: After all the melts are melted, the melt temperature is controlled at 1300-1350°C, and then the slag cleaning agent is added in two times, and the oxide slag cle...

Embodiment 2

[0057] Example 2: Preparation of a copper-iron alloy wire rod with a diameter of 2mm and iron content of 8.45%. The process flow of the copper-iron alloy wire rod is: batching→melting and casting→slagging converter→removing impurities and degassing→horizontal continuous casting→cold rolling→ Annealing→drawing, specifically:

[0058] 1) Ingredients: Weigh the electrolytic copper plate, copper-iron master alloy according to the composition, Fe in the copper-iron master alloy: 48-52wt%;

[0059] 2) Smelting: adding the electrolytic copper plate and the copper-iron intermediate alloy into the smelting furnace to heat up and melt in sequence;

[0060] 3) Slag removal converter: After all the melts are melted, the melt temperature is controlled at 1380-1420°C, and then the slag cleaning agent is added in two times, and the oxide slag cleaning agent is added for the first time, and the addition amount is 0.4% of the total mass of the ingredients. Stir well from top to bottom after a...

Embodiment 3

[0066] Example 3: Preparation of a copper-iron alloy wire rod with a diameter of 2 mm and iron content of 10.21%. The process flow of the copper-iron alloy wire rod is: batching → melting and casting → slag removal converter → impurity removal, degassing → vertical continuous casting → cold rolling → Annealing→drawing, specifically:

[0067] 1) Ingredients: Weigh the electrolytic copper plate, copper-iron master alloy according to the composition, Fe in the copper-iron master alloy: 48-52wt%;

[0068] 2) Smelting: adding the electrolytic copper plate and the copper-iron intermediate alloy into the smelting furnace to heat up and melt in sequence;

[0069]3) Slag removal converter: After all the melts are melted, the melt temperature is controlled at 1380-1450°C, and then the slag cleaning agent is added in two times, and the oxide slag cleaning agent is added for the first time, and the addition amount is 0.4% of the total mass of the ingredients. Stir well from top to bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com