Compound dispergator added with plant essence and preparation process thereof

A compound debonding agent and plant essence technology, which is applied in the field of ceramic fine chemicals, can solve the problems of unstable differential adaptability, poor mud stability, and poor degumming adaptability, etc., and achieve a wide range of water quality, easy molding, and enhanced hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

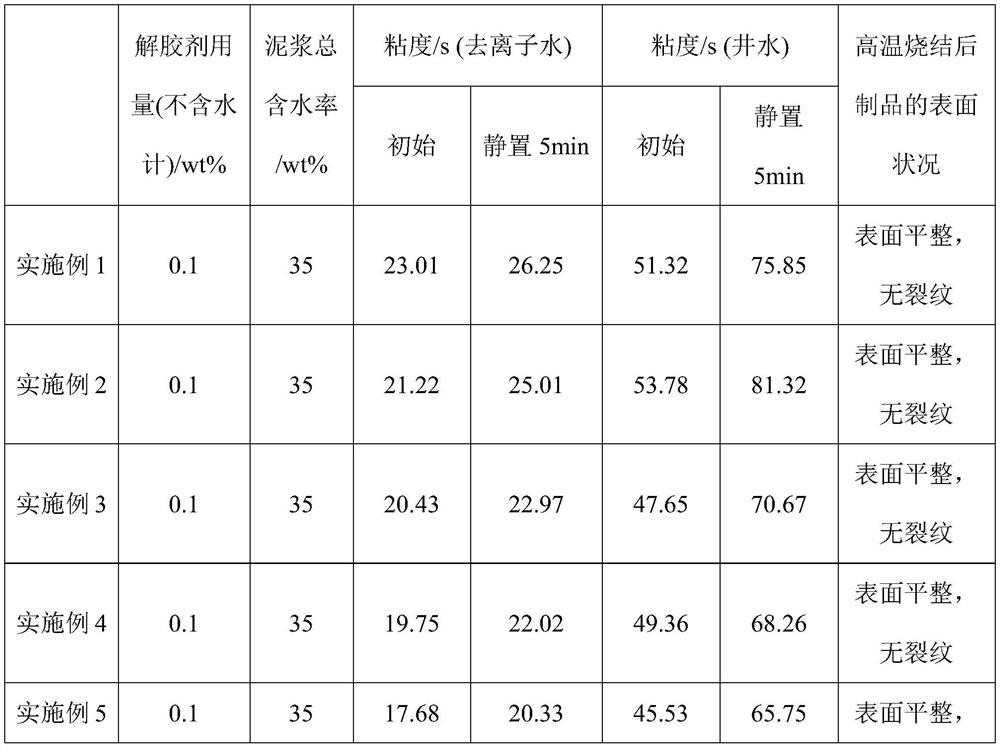

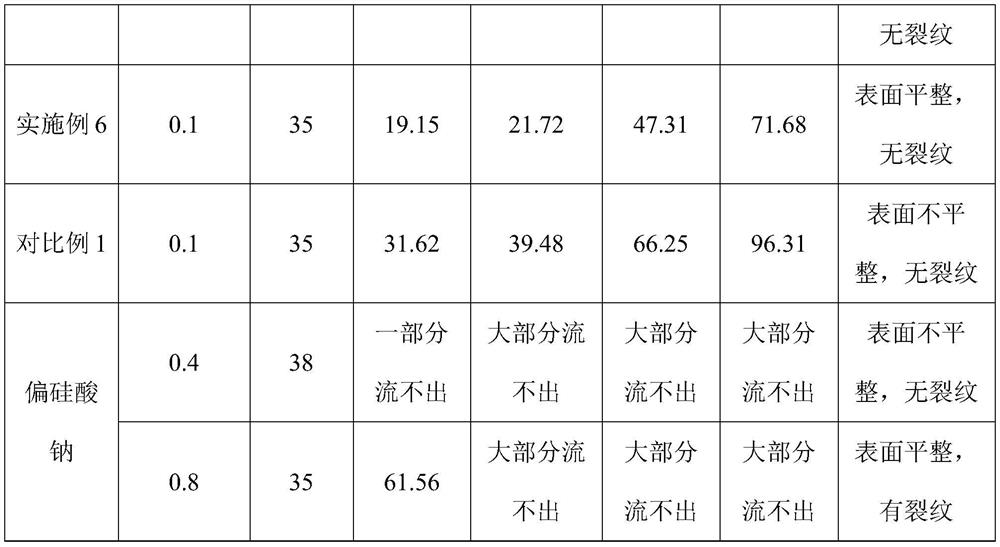

Examples

Embodiment 1

[0025] A compound debonding agent added with plant essence, comprising the following raw materials in parts by weight: 15 parts of sodium aminotrimethylene phosphate, 15 parts of sodium ethylenediamine tetramethylene phosphonate, 15 parts of sodium diethylene triamine pentamethylene phosphonate 2.5 parts of inulin, 2.5 parts of fructan, 5 parts of sodium polyacrylate, 5 parts of sodium silicate, and 5 parts of sodium metasilicate.

[0026] The above raw materials are weighed in parts by weight, and mixed uniformly to obtain a solid debonding agent; 1.5 times of water by weight is added to the obtained solid degumming agent to obtain a composite degumming agent.

Embodiment 2

[0028] A compound degumming agent added with plant essence, including the following raw materials in parts by weight: 10 parts of sodium N-2 hydroxyethyl-N-dimethylidene phosphonate, 5 parts of α-glucan oligosaccharides, and 5 parts of glycine , 5 parts of tannic acid, 15 parts of sodium polyacrylate, 15 parts of potassium polyacrylate, 20 parts of potassium silicate, 5 parts of sodium citrate, 5 parts of sodium gluconate, 5 parts of sulfonated lignin, 5 parts of lignosulfonate share.

[0029] The above raw materials are weighed in parts by weight and mixed evenly to obtain a solid debonding agent; 3.5 times of water by weight is added to the obtained solid degumming agent to obtain a composite degumming agent.

Embodiment 3

[0031] Plant essence: Extracted from grapes, peas, cauliflower, onions, and rice.

[0032] A compound debonding agent added with plant essence, including the following raw materials in parts by weight: 20 parts of ethoxyethyl diamine tetramethylene phosphonate, 1,3-diamine-2-propanol tetramethylene phosphonic acid 20 parts of salt, 20 parts of plant essence, 20 parts of sodium polyacrylate, 20 parts of sodium silicate, 20 parts of sodium metasilicate, 4 parts of sodium lactate, 4 parts of potassium citrate, 4 parts of sulfonated enzymatic lignin, carboxylated alkali 4 parts of lignin, 0.1 part of tripropylene phosphite as a phosphorous additive.

[0033] Weigh the above-mentioned raw materials by weight, add 2 times the weight of water, and mix evenly to obtain a composite debonding agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com