Recycling process for synchronously enhancing anaerobic acid production and phosphorus recovery of sludge

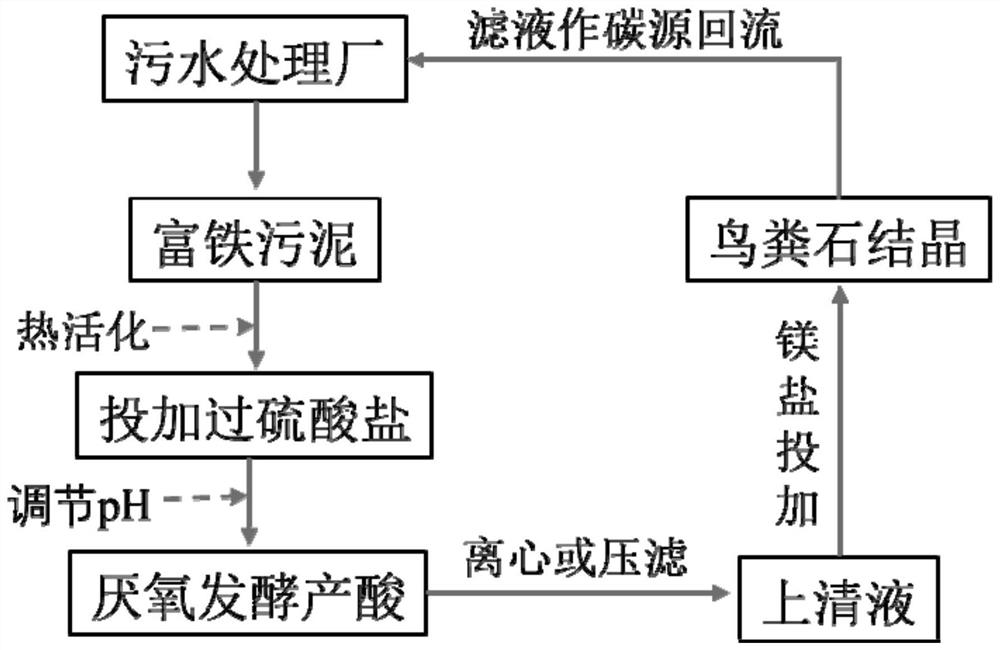

A phosphorus recovery and resource utilization technology, applied in the field of sludge resource utilization, can solve the problems of increasing Fe-P, low phosphorus release efficiency, and limited popularization and application, so as to promote the hydrolysis of organic matter, strengthen the anaerobic fermentation of sludge to produce acid, Effect of Strengthening Anaerobic Phosphorus Release from Sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

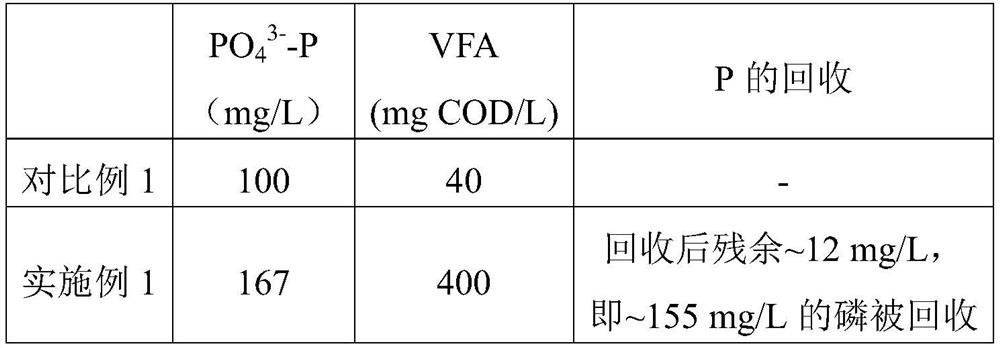

Embodiment 1

[0035] The sludge used in this example is the mixed sludge of the activated sludge of biological phosphorus removal in a certain sewage treatment plant in Suzhou and the chemical sludge of iron salt enhanced phosphorus removal, and its total solids (TS) and volatile solids (VS) are respectively 2.51% and 1.59%, VS / TS=63.34%; the domesticated inoculum slime has the ability to stably reduce sulfate radical, among which TS=2.50%, VS / TS=44.51%.

[0036] Add 0.125mmol / gTS sodium persulfate to the sludge, at this time the molar ratio S:Fe=0.5, shake in a high-temperature shaker at 80°C for 2 hours, cool to room temperature, the pH of the sludge drops from 6.8 to 5.4, and use 1M NaOH was used to adjust the sludge pH to 7.0. The pre-oxidized sludge and inoculum sludge were mixed into the anaerobic fermentation tank according to the TS mass ratio of 2:1, and batch experiments were carried out under the conditions of 37 °C water bath and 100 r / min stirring conditions.

[0037] The cont...

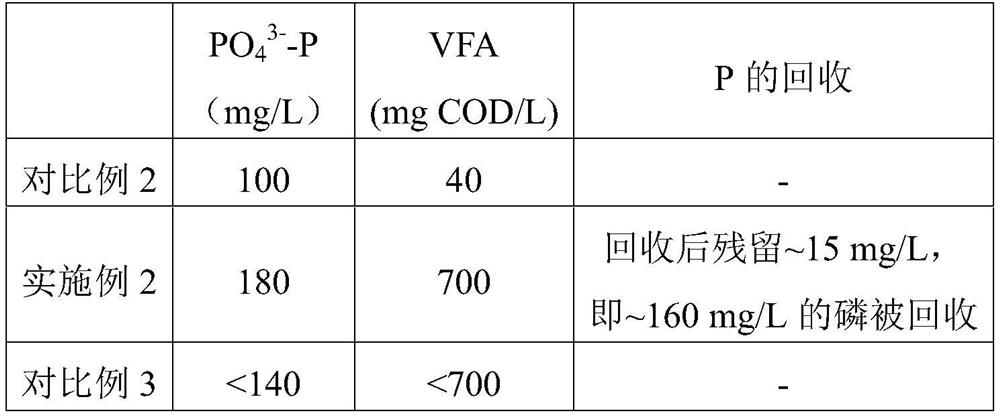

Embodiment 2

[0045] The sludge used in the experiment is the primary sludge of a sewage treatment plant for iron-salt enhanced phosphorus removal, in which TS=2.46%, VS=1.53%, VS / TS=62.20%; the domesticated seed sludge has the ability to stably reduce sulfate , where TS=2.50%, VS / TS=44.51%.

[0046] Add 0.3mmol / g TS sodium persulfate to the sludge. At this time, the molar ratio S:Fe=2. Shake in a high-temperature shaker at 80°C for 2 hours, cool to room temperature, and the sludge is reduced from 6.5 to 4.5. Use 1M NaOH was used to adjust the sludge pH to 7.0. The pre-oxidized sludge and inoculum sludge were mixed into the anaerobic fermentation tank according to the TS mass ratio of 2:1, and batch experiments were carried out under the conditions of 37 °C water bath and 100 r / min stirring conditions.

[0047] The contents of volatile fatty acids (VFAs) and dissolved phosphorus were measured daily during the experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com