Lactoferrin-rich active lactobacillus beverage and preparation method thereof

A technology of active lactic acid bacteria and lactoferrin, applied in the field of fermented dairy product processing, to achieve the effects of reducing production costs, good flavor and stability, and accelerating fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

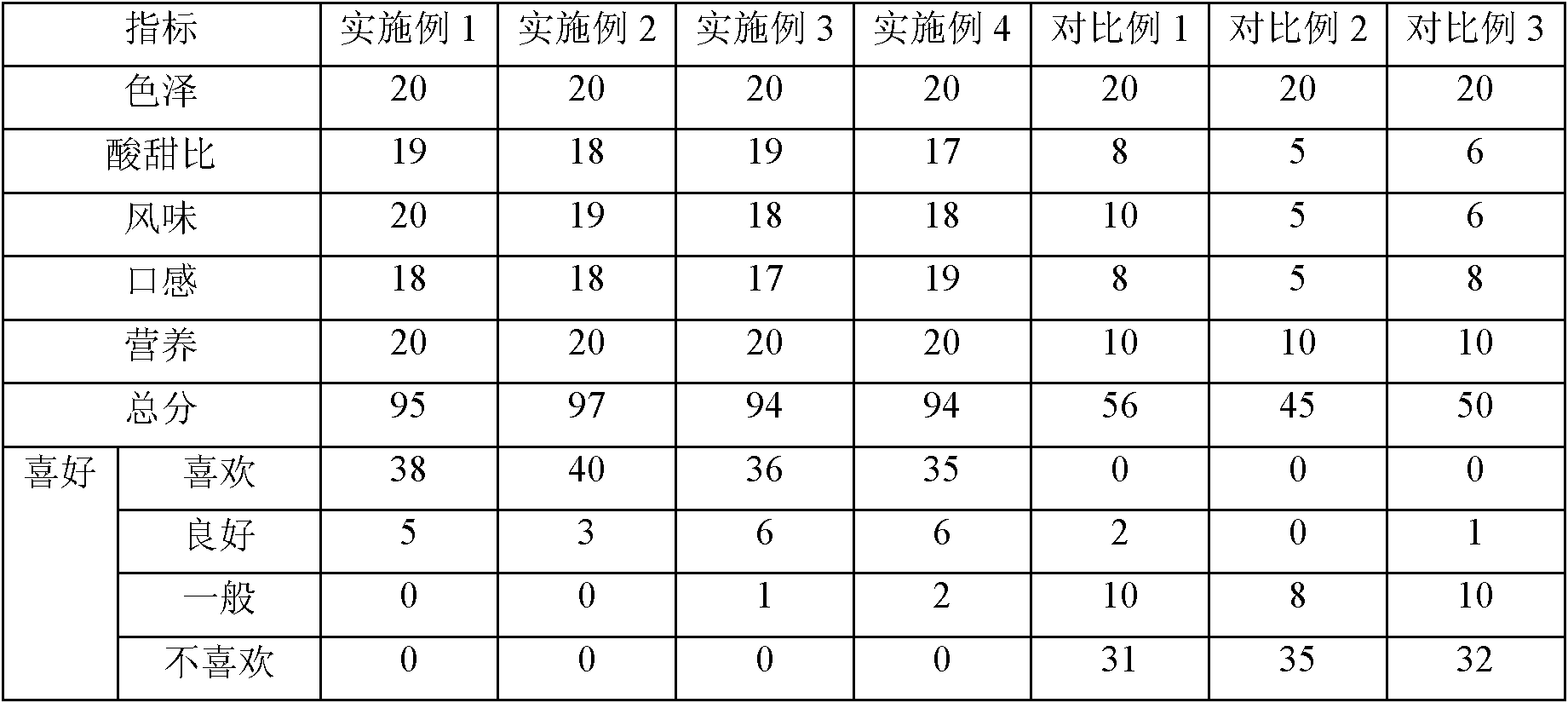

Examples

Embodiment 1

[0039] 1. Raw material formula

[0040] 1. Yogurt base (1 ton): 955 kg of whole milk; 10 kg of glucose; 3 kg of soybean protein powder; 30 kg of white sugar; 2 kg of lactoferrin; ): 250DCU.

[0041] 2. Beverage ratio (calculated by 1 ton): 400 kg of yogurt base; 160 kg of white sugar; 5 kg of CMC; 1.5 kg of pectin; the balance of water.

[0042] 2. Preparation method:

[0043] 1. Yogurt base:

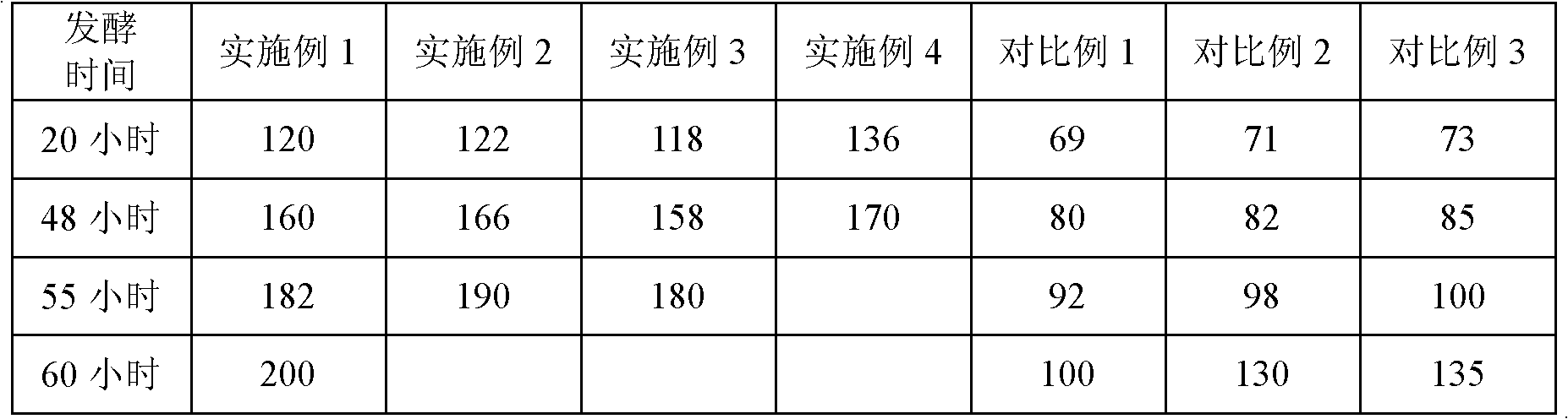

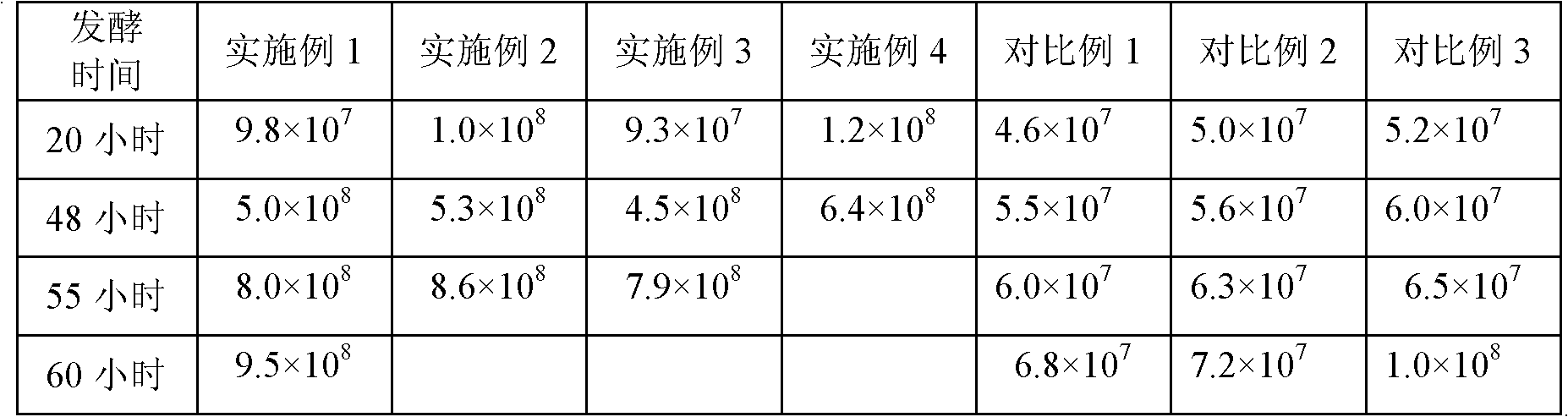

[0044] Dissolve soybean protein powder, white sugar, and glucose in milk at 50°C; then homogenize at 50°C and 15MPa pressure, and sterilize at 90°C for 150 minutes; then cool to 36°C, add fermented strains for fermentation and lactoferrin Egg whites, stirred evenly, fermented at 36°C for 60 hours, stopped the fermentation when the titrated acidity reached 200°T, and obtained the yogurt base material, which was set aside.

[0045] 2. Milk beverage preparation method:

[0046] Mix white sugar and stabilizer evenly at 60°C, dissolve in water to obtain sugar liquid, sterilize at 85°C f...

Embodiment 2

[0050] 1. Raw material formula

[0051] 1. Yogurt base material (based on 1 ton): glucose 15 kg; soybean protein powder 5 kg; white sugar 40 kg; lactoferrin 1.5 kg; strain (Hansen L. casei-01) 250DCU; skimmed fresh milk margin.

[0052] 2. Beverage ratio (based on 1 ton): yogurt base 400 kg; white sugar 150 kg; pectin 4 kg; water balance.

[0053] 2. Preparation method:

[0054] 1. Yogurt base:

[0055] Dissolve soybean protein powder, white sugar, and glucose in milk at 55°C; then homogenize at 55°C and 20MPa pressure, and sterilize at 100°C for 120 minutes; then cool to 37°C, add fermented strains for fermentation and lactoferrin Egg whites, stirred evenly, fermented at 37°C for 55 hours, stopped the fermentation when the titrated acidity reached 190°T, and obtained the yogurt base material for later use.

[0056] 2. Milk beverage preparation method:

[0057] Mix white sugar and stabilizer evenly at 70°C, dissolve in water to obtain sugar liquid, sterilize at 95°C for 1...

Embodiment 3

[0061] 1. Raw material formula

[0062] 1. Yogurt base material (based on 1 ton): 25 kg of glucose; 7 kg of soybean protein powder; 50 kg of white sugar; 4 kg of lactoferrin; margin.

[0063] 2. Beverage ratio (based on 1 ton): yogurt base 250 kg; white sugar 130 kg; soybean polysaccharide 4 kg; water balance.

[0064] 2. Preparation method:

[0065] 1. Yogurt base:

[0066] Dissolve soybean protein powder, white sugar, and glucose in milk at 40°C; then homogenize at 40°C and 25MPa pressure, and sterilize at 110°C for 90 minutes; then cool to 43°C, add fermented strains for fermentation and lactoferrin Egg whites, stirred evenly, fermented at 43°C for 55 hours, stopped the fermentation when the titrated acidity reached 180°T, and obtained the yogurt base material for later use.

[0067] 2. Milk beverage preparation method:

[0068] Mix white granulated sugar and stabilizer evenly at 75°C, dissolve in water to obtain sugar liquid, sterilize at 105°C for 5 minutes, then coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com