Beneficiation method of high-sulfur lead zinc ores under high-temperature environment

A beneficiation method and high-temperature environment technology, applied in flotation, solid separation and other directions, can solve problems such as lead and zinc flotation interference, and achieve the effects of stable process, strong adaptability to ore properties, and efficient beneficiation and smelting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]The annual temperature in a high-sulfur lead-zinc mine area is above 35°C, and the temperature in some months is above 45°C; affected by factors such as heat dissipation of the mill, flotation machine, and sand pump, the temperature of the ore pulp entering the flotation after grinding will decrease. At 45-57°C. The raw ore of this high-sulfur lead-zinc ore contains 1.72% lead, 8.42% zinc and 22.54% sulfur. The process mineralogy research of this high-sulfur lead-zinc ore shows that the lead-containing minerals in this ore are mainly galena, followed by a small amount of white leadite; Zinc ore, etc.; sulfur-containing minerals are mainly marcasite and pyrite, of which marcasite accounts for 28% of the total mineral composition; gangue minerals are mainly quartz, calcite, mica, kaolin, feldspar, etc.; it is a typical Marcasite-type high-sulfur lead-zinc ores in a high-temperature environment.

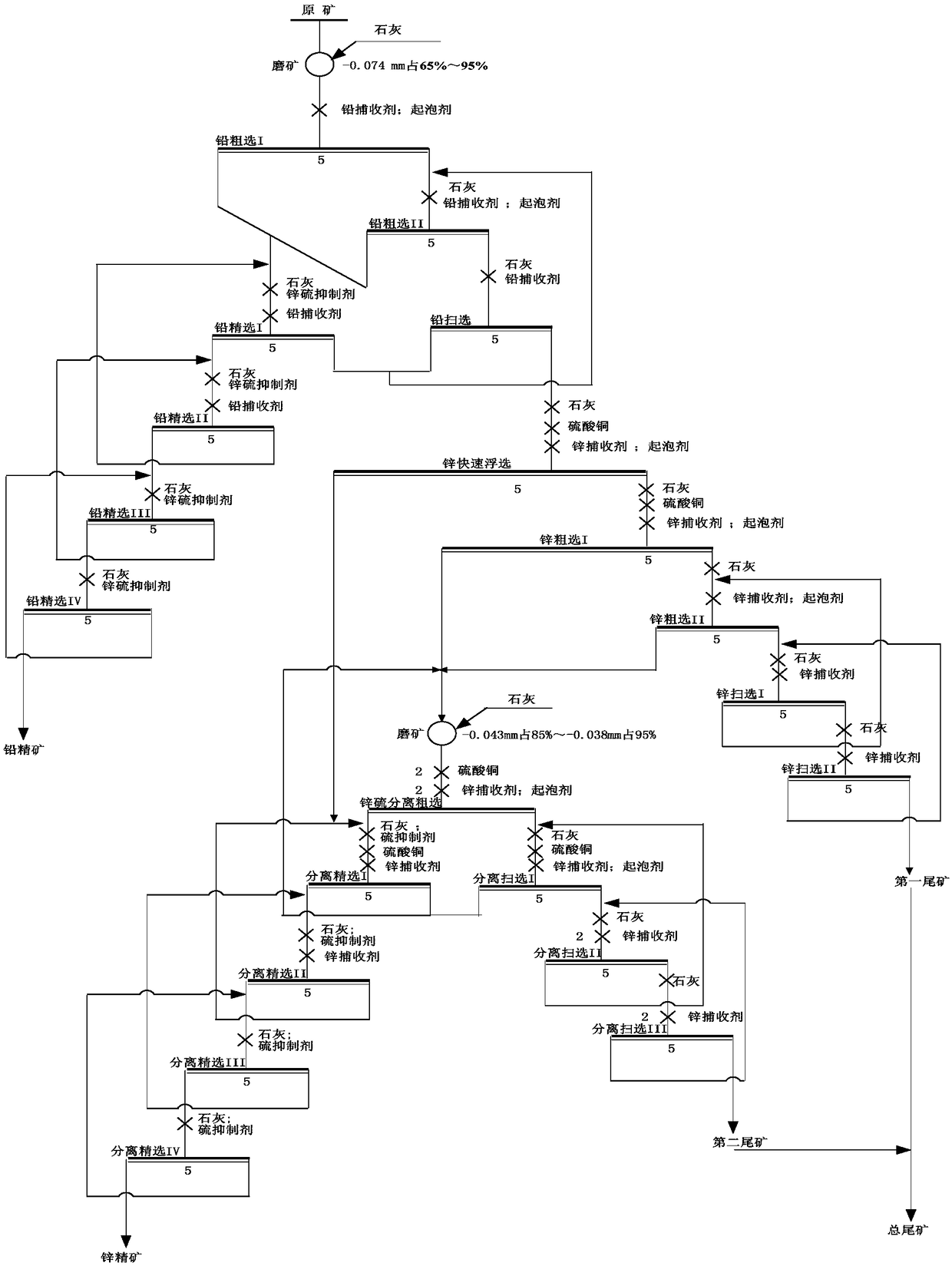

[0053] Such as figure 1 Shown, a kind of beneficiation method of high-sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com