UV-cured self-repairing polyurethane acrylate coating and preparation method thereof

A polyurethane acrylate, self-healing technology, applied in the field of coatings, can solve problems such as poor durability, long time required, and low repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

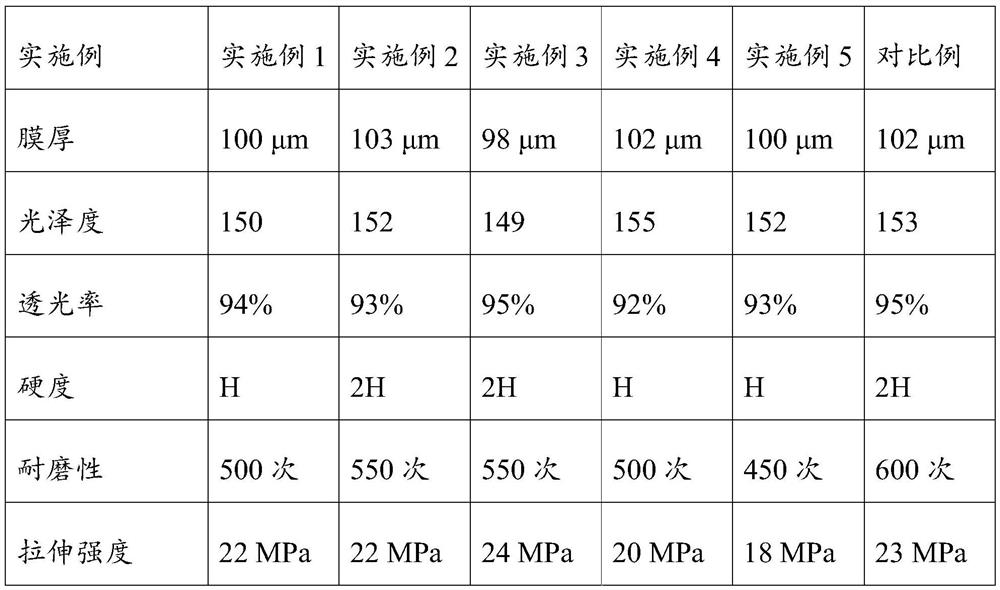

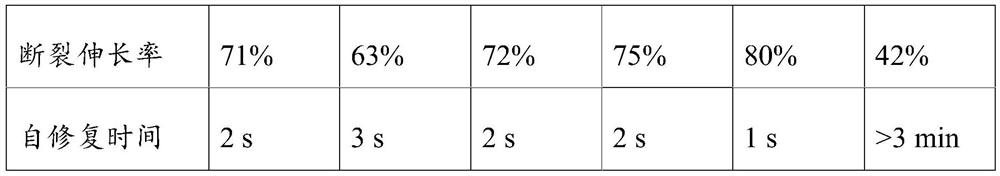

Examples

Embodiment 1

[0025] The UV curing polyurethane acrylate coating of the present invention comprises the following components by weight: 25 parts of isophorone diisocyanate, 48 parts of polycaprolactone diol (molecular weight 1000), 3.5 parts of butanediol, furfuryl alcohol / maleic acid 10 parts of hydroxyethyl imide / hydroxyethyl acrylate (0.5:0.5:1) composition, 0.05 part of p-hydroxyanisole, 0.05 part of stannous octoate, 2-hydroxy-2-methyl-1-phenylacetone 0.8 parts, 0.5 parts of BYK-333 leveling agent, 10 parts of ethyl acrylate and 90 parts of butyl acetate.

[0026] The preparation method of this UV curing polyurethane acrylate coating is as follows:

[0027] Put the dried polycaprolactone diol and isophorone diisocyanate into the reaction kettle, mix, melt and stir, when the temperature rises to 70°C, add stannous octoate, control the temperature at 80°C and stir the reaction under nitrogen protection for 1.5 h; after that, butanediol was added, and the stirring reaction was continued ...

Embodiment 2

[0029] UV curing polyurethane acrylate coating of the present invention comprises following components by weight: 23 parts of toluene diisocyanate, 45 parts of polypropylene glycol (molecular weight 1000), 3 parts of butanediol, furfuryl alcohol / maleimide hydroxyethyl ester / acrylic acid 9 parts of hydroxyethyl ester (0.5:0.5:1) composition, 0.05 part of p-hydroxyanisole, 0.05 part of stannous octoate, 1 part of 2-hydroxy-2-methyl-1-phenylacetone, BASF Tinuvin 1130 0.6 10 parts, 10 parts of isooctyl acrylate and 80 parts of toluene.

[0030] The preparation method of this UV curing polyurethane acrylate coating is as follows:

[0031] Put the dry and dehydrated polypropylene glycol and toluene diisocyanate into the reaction kettle, mix, melt and stir, add stannous octoate when the temperature rises to 70°C, control the temperature at 75°C and stir for 2 hours under nitrogen protection; then add butanediol , Continue to stir and react at 75°C for 1.5h to obtain a polyurethane p...

Embodiment 3

[0033] The UV curing polyurethane acrylate coating of the present invention comprises the following components by weight: 30 parts of dicyclohexylmethane-4,4'-diisocyanate, 50 parts of polytetrahydrofuran diol (molecular weight 2000), 3 parts of hexanediol, furfuryl alcohol / hydroxyethyl maleimide / hydroxyethyl acrylate (0.5:0.5:1) composition 11 parts, 2,5-di-tert-butylhydroquinone 0.05 parts, dibutyltin dilaurate 0.06 parts, 1 - 1.2 parts of hydroxycyclohexyl phenyl ketone, 0.05 parts of BYK BYK052 defoamer, 0.05 parts of BYK-333 leveling agent, 15 parts of 1,6-hexanediol diacrylate and ethyl acetate / propylene glycol methyl Ether acetate (1:2) 90 parts.

[0034] The preparation method of this UV curing polyurethane acrylate coating is as follows:

[0035] Put the dried and dehydrated polytetrahydrofuran diol and dicyclohexylmethane-4,4'-diisocyanate into the reaction kettle, mix, melt and stir, add dibutyltin dilaurate when the temperature rises to 70°C, control the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com