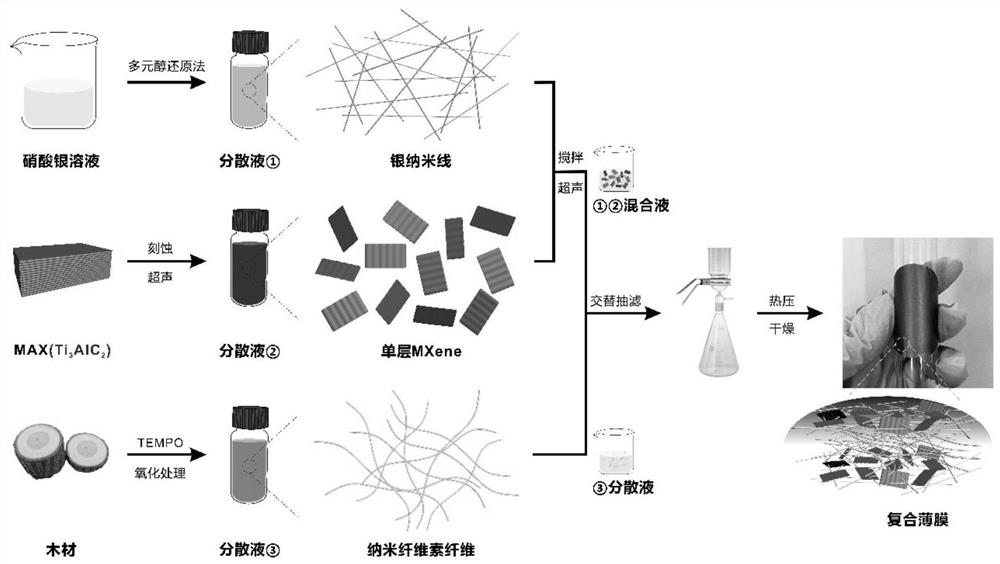

Nanocellulose/MXene/silver nanowire sandwich structure composite film and preparation method thereof

A technology of nanocellulose and silver nanowires, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of high surface roughness and poor mechanical and chemical stability of pure silver nanowire films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of MXene / silver nanowire / nanocellulose composite film and preparation method thereof, comprising the following process steps:

[0046] (1) Dissolve 0.1g of sodium bromide and 0.015g of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) in 100mL of deionized water; crush 1g of softwood pulp and add the above mixed solution In the process, stir mechanically for 5 minutes, ultrasonically for 20 minutes to further disperse evenly; slowly add 5 mmol / g sodium hypochlorite solution dropwise at 30°C, and stir while adding; add 0.5M sodium hydroxide dropwise to maintain the pH value of the above dispersion at 9.7~ 10.2 After reacting for 5 hours, add 10 mL of ethanol dropwise, and then add hydrochloric acid solution dropwise to adjust the pH value to about 7; wash the above-mentioned oxidized wood pulp fibers with deionized water, disperse the washed product in water, and centrifuge at 9000 rpm for 40 minutes at high speed. Collect the supernatant; process the supernata...

Embodiment 2

[0054] A kind of MXene / silver nanowire / nanocellulose composite film and preparation method thereof, comprising the following process steps:

[0055] (1) Dissolve 0.11g of sodium bromide and 0.018g of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) in 100mL of deionized water; pulverize 1.5g of softwood pulp, add the above mixed In the solution, mechanically stir for 10 minutes, ultrasonic for 15 minutes to further disperse evenly; slowly add 4mmol / g sodium hypochlorite solution dropwise at 35°C, and stir while adding; add 0.5M sodium hydroxide dropwise to maintain the pH value of the above dispersion at 9.7 ~10.2, after reacting for 5 hours, add 15mL ethanol dropwise, then add dropwise hydrochloric acid solution to adjust the pH value to about 7; wash the above-mentioned oxidized wood pulp fiber with deionized water, disperse the washed product in water, and centrifuge at 10000rpm for 30min , collect the supernatant; process the supernatant with a high-pressure homogenize...

Embodiment 3

[0063] A kind of MXene / silver nanowire / nanocellulose composite film and preparation method thereof, comprising the following process steps:

[0064] (1) Dissolve 0.1g of sodium bromide and 0.016g of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) in 100mL of deionized water; crush 1.5g of coniferous wood pulp, add the above mixed In the solution, mechanically stir for 10 minutes, ultrasonic for 15 minutes to further disperse evenly; slowly add 5 mmol / g sodium hypochlorite solution dropwise at 30°C, and stir while adding; add 0.5M sodium hydroxide dropwise to maintain the pH value of the above dispersion at 9.7 ~10.2, after reacting for 5 hours, add 15mL ethanol dropwise, then add dropwise hydrochloric acid solution to adjust the pH value to about 7; wash the above-mentioned oxidized wood pulp fiber with deionized water, disperse the washed product in water, and centrifuge at 10000rpm for 30min , collect the supernatant; process the supernatant with a high-pressure homogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com