Modified polylactic acid material

A polylactic acid material and polylactic acid technology, applied in the field of polymers, can solve problems such as poor mechanical strength, achieve the effects of increased elongation at break, simple synthesis path, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

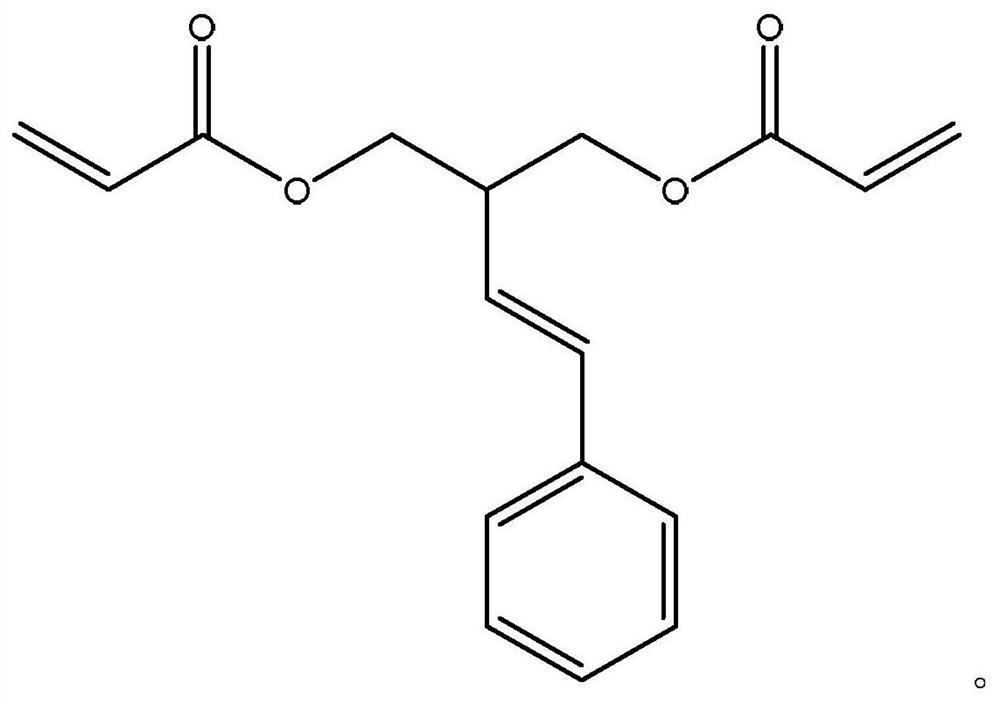

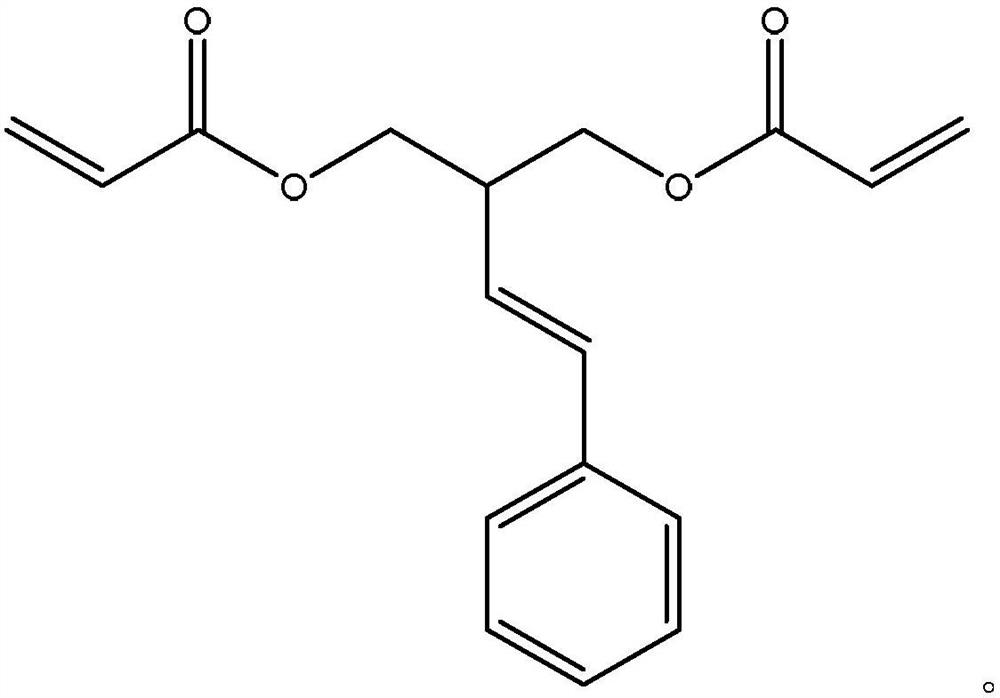

[0043] Synthesis of cinnamon acetal ethyl diacrylate:

[0044] Take parts by mass

[0045] Cinnamaldehyde: 10 parts

[0046] Trimethyl orthoformate: 20 parts

[0047] Hydroxyethyl acrylate: 20 parts

[0048] Toluenesulfonic acid: 0.1 parts.

[0049] Step A: Take cinnamaldehyde and trimethyl orthoformate, dissolve them in a methanol solution with 80 parts by weight, add 0.05 parts of toluenesulfonic acid as a catalyst, and keep stirring at 1000 r / min at 65°C. After reacting for 6 hours, the cinnamon diacetal was extracted, the extraction process was extracted with dichloromethane, and the organic layer was collected to obtain the cinnamon diacetal;

[0050] Step B: Add hydroxyethyl acrylate to the cinnamon diacetal obtained in step A, and add 80 parts by weight of chloroform as a solvent, then add 0.05 parts of toluenesulfonic acid as a catalyst, and keep at 65°C at 1000r / min Under stirring, react for 6 hours to obtain ethyl cinnamon acetal diacrylate.

[0051] The ethyl ...

Embodiment 2

[0053] Polylactic acid: 80 parts

[0054] Dicumyl peroxide: 1 part

[0055] tert-butylhydroquinone: 1 part

[0056] Dioctyl phthalate: 1 part

[0057] Cinnamon acetal ethyl diacrylate prepared in Example 1: 5 parts;

[0058] Mix polylactic acid, solubilizer, antioxidant, plasticizer, and cinnamon acetal ethyl diacrylate evenly, add them to a twin-screw extruder, heat up to 150°C for extrusion, and the extrusion time is 5 minutes to obtain Modified polylactic acid material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com