Aluminium alloy material, mobile phone shell and manufacturing method thereof

A technology of aluminum alloy material and mobile phone case, which is applied in the field of mobile phone case and its production, and aluminum alloy materials, can solve the problems of mobile phone case wear resistance and poor pressure resistance, complex process, low tensile strength of aluminum alloy mobile phone case, etc. Achieve the effects of improving wear resistance and pressure resistance, improving performance, and reducing pore defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, the aluminum alloy material is composed of the following components in mass percentage: 1.2% silicon, 2% nickel, 1.4% chromium, 1% titanium, 0.02% lanthanum rare earth, and the balance is aluminum.

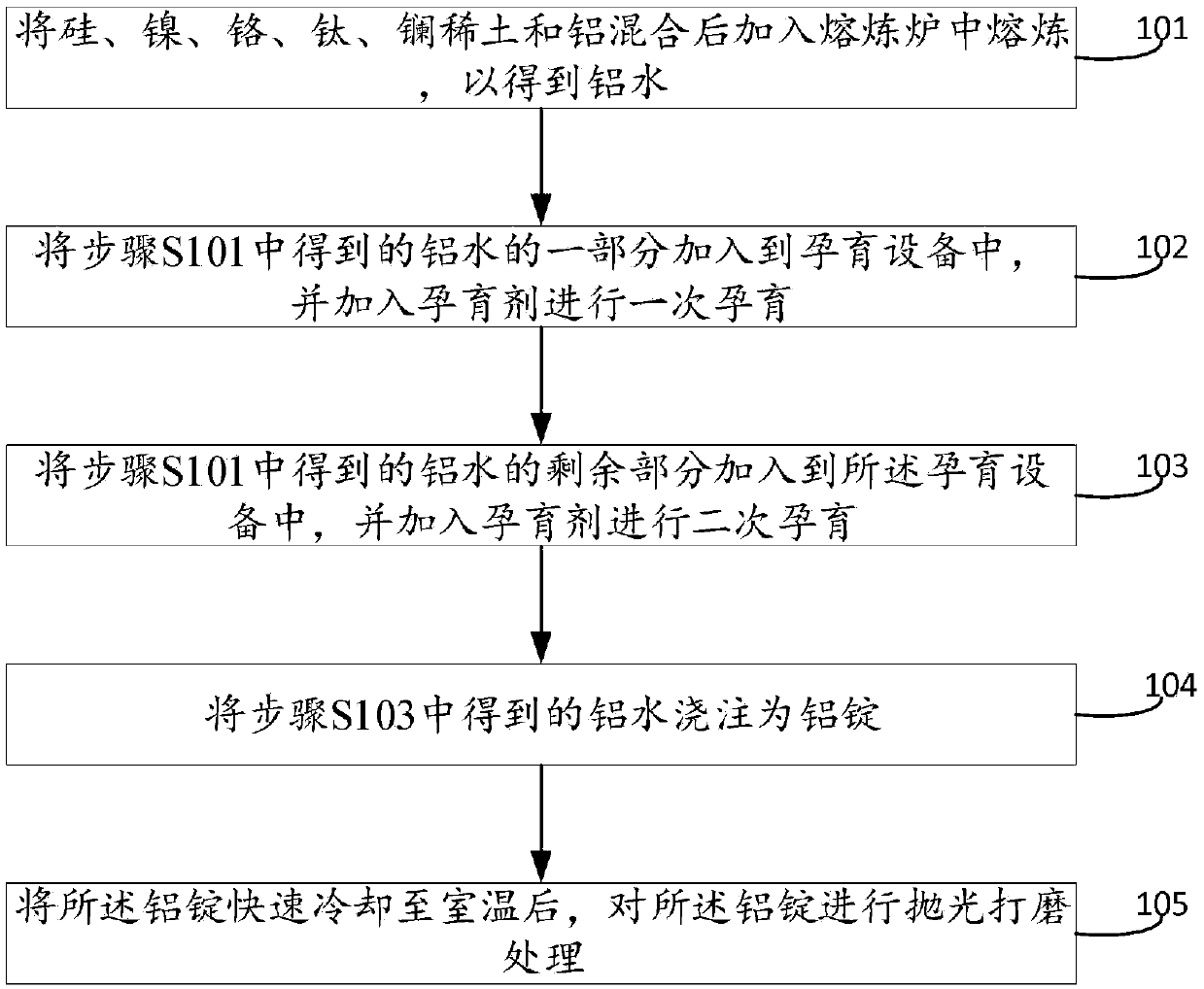

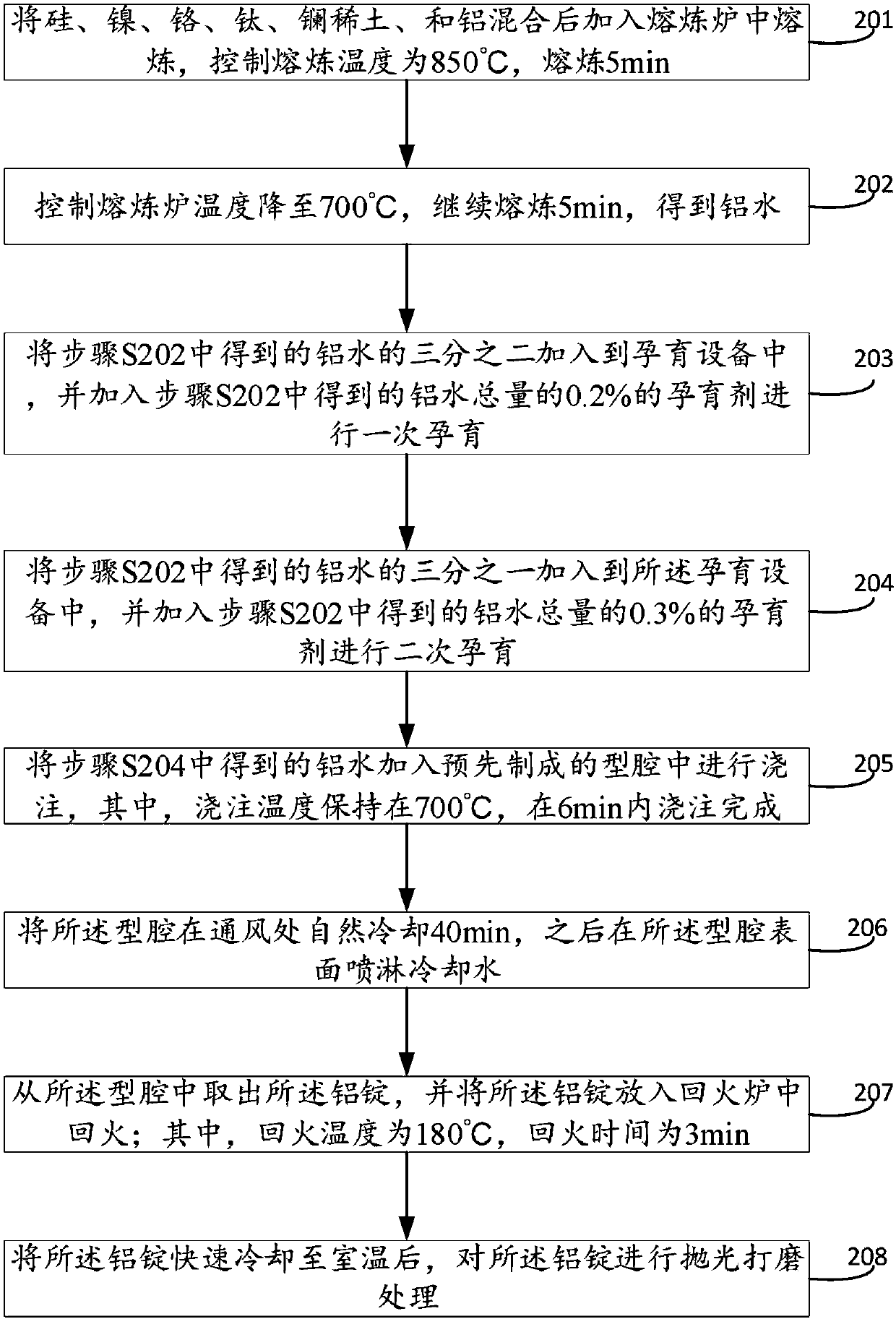

[0049] see figure 2 , The method for producing an aluminum alloy material proposed in this embodiment includes the following steps S201-S208.

[0050]S201, mix silicon, nickel, chromium, titanium, lanthanum rare earth, and aluminum into a melting furnace for smelting, control the smelting temperature to 850°C, and smelt for 5 minutes.

[0051] S202, then controlling the temperature of the smelting furnace to drop to 700° C., and continuing smelting for 5 minutes to obtain molten aluminum.

[0052] S203, adding 2 / 3 of the aluminum water obtained in the step S202 to the inoculation equipment, and adding an inoculant of 0.2% of the total amount of the aluminum water obtained in the step S202 to inoculate once.

[0053] S204, adding one-third of the alumi...

Embodiment 2

[0059] In this embodiment, the aluminum alloy material is composed of the following components in mass percentage: 2.3% silicon, 4% nickel, 2.6% chromium, 3% titanium, 0.08% lanthanum rare earth, and the balance is aluminum.

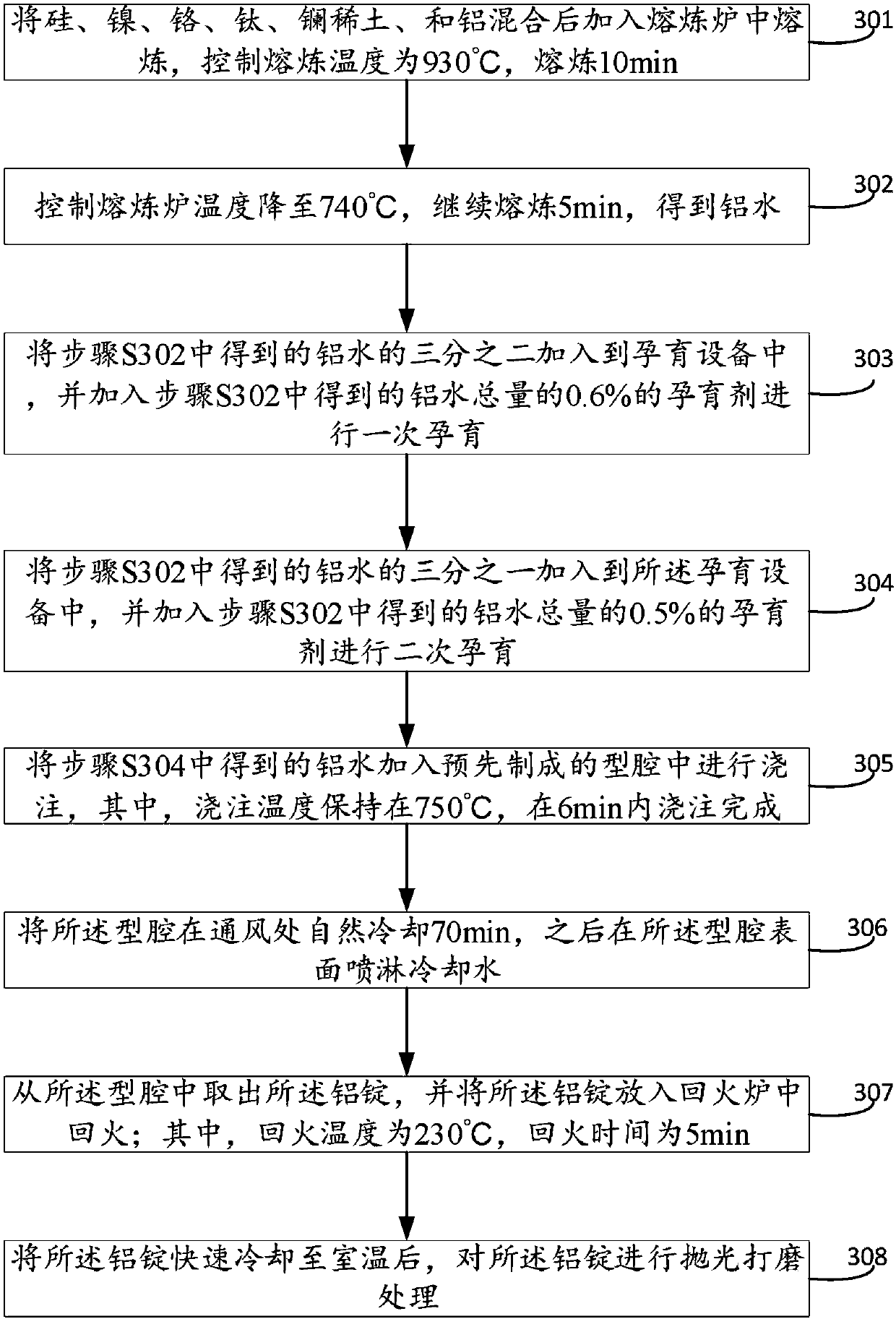

[0060] see image 3 , The method for producing an aluminum alloy material proposed in this embodiment includes the following steps S301-S308.

[0061] S301, mix silicon, nickel, chromium, titanium, lanthanum rare earth, and aluminum into a smelting furnace for smelting, control the smelting temperature to 930°C, and smelt for 10 minutes.

[0062] S302, then controlling the temperature of the smelting furnace to drop to 740° C., and continuing smelting for 5 minutes to obtain molten aluminum.

[0063] S303, adding 2 / 3 of the aluminum water obtained in the step S302 to the inoculation equipment, and adding an inoculant of 0.6% of the total amount of the aluminum water obtained in the step S302 to inoculate once.

[0064] S304, adding one-third of the alu...

Embodiment 3

[0070] In this embodiment, the aluminum alloy material is composed of the following components in mass percentage: 1.3% silicon, 2.2% nickel, 1.5% chromium, 1.2% titanium, 0.03% lanthanum rare earth, and the balance is aluminum.

[0071] see Figure 4 , The method for producing an aluminum alloy material proposed in this embodiment includes the following steps S401-S408.

[0072] S401, mix silicon, nickel, chromium, titanium, lanthanum rare earth, and aluminum into a smelting furnace for smelting, control the smelting temperature to 860°C, and smelt for 6 minutes.

[0073] S402, then control the temperature of the smelting furnace to drop to 710° C., and continue smelting for 5 minutes to obtain molten aluminum.

[0074] S403, adding 2 / 3 of the aluminum water obtained in the step S402 to the inoculation equipment, and adding an inoculant of 0.3% of the total amount of the aluminum water obtained in the step S402 to inoculate once.

[0075] S404, adding one-third of the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com