Glass fiber reinforced plastic reinforced metal pipeline

A technology of metal pipes and glass fiber reinforced plastics, applied in the direction of pipe protection, pipe damage/wear prevention, pipes, etc., can solve the problems of poor pull-out resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in more detail below with reference to the accompanying drawings and reference numerals, so that those skilled in the art can implement it after studying this specification. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

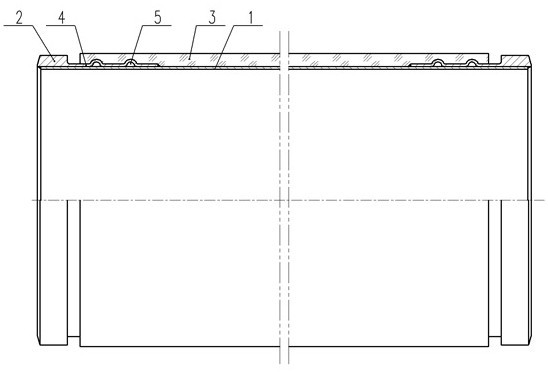

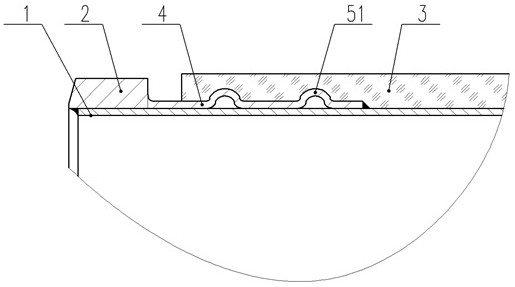

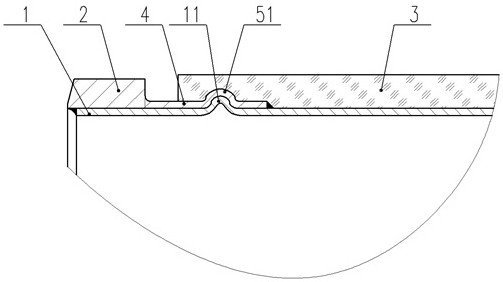

[0020] The present invention provides such Figure 1-4 A glass-reinforced steel pipe is shown, comprising an inner pipe 1, two joints 2 respectively arranged on the outer walls of both ends of the inner pipe 1 and a reinforcing layer 3 arranged on the outer surface of the inner pipe 1, the joints 2 A connection part 4 is provided towards one end of the reinforcement layer 3, the connection part 4 extends between the inner tube 1 and the reinforcement layer 3, and the connection part 4 is at the junction with the reinforcement layer 3 At least one protruding structure 5 for strengthenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com