Reinforcing filler functional additive, and application thereof in silica-filled SSBR compound

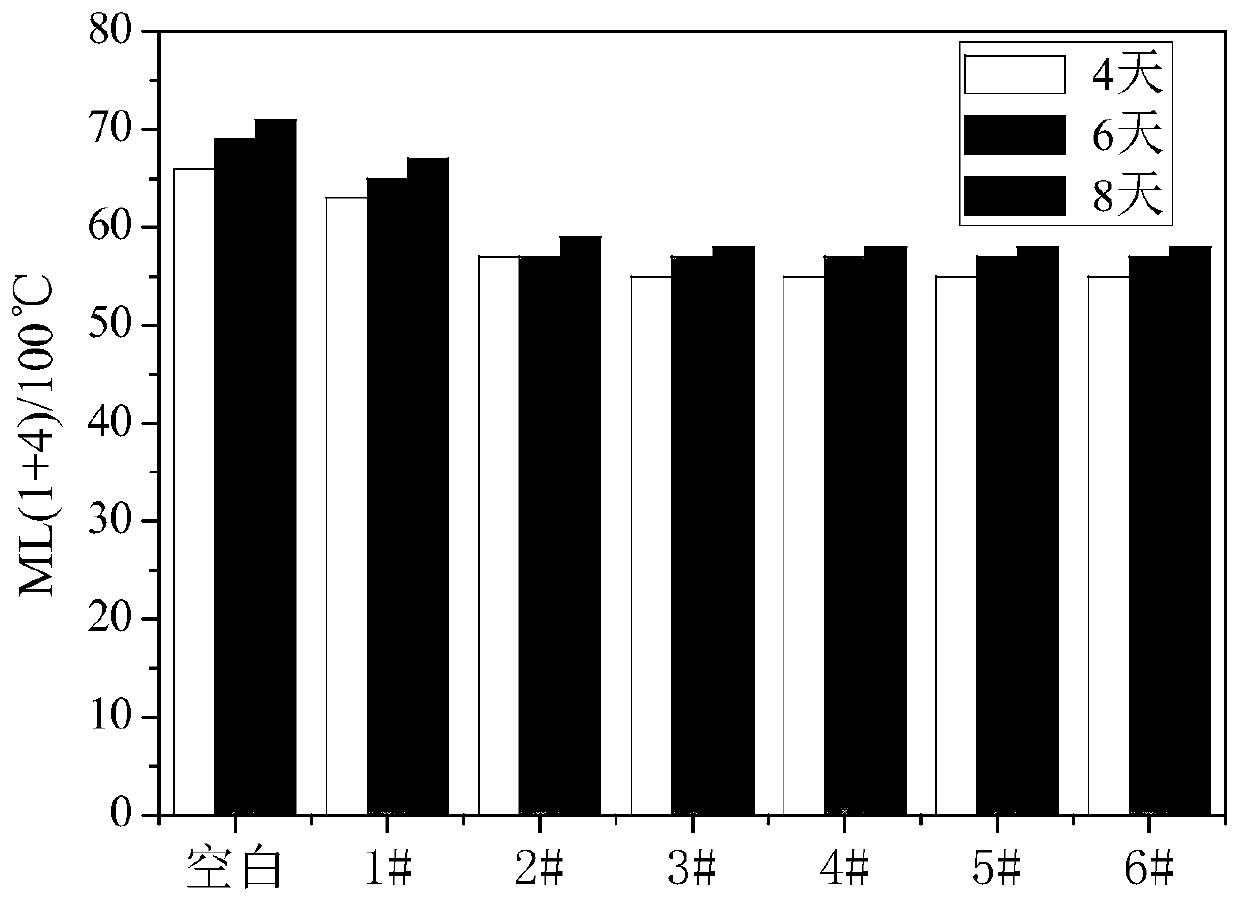

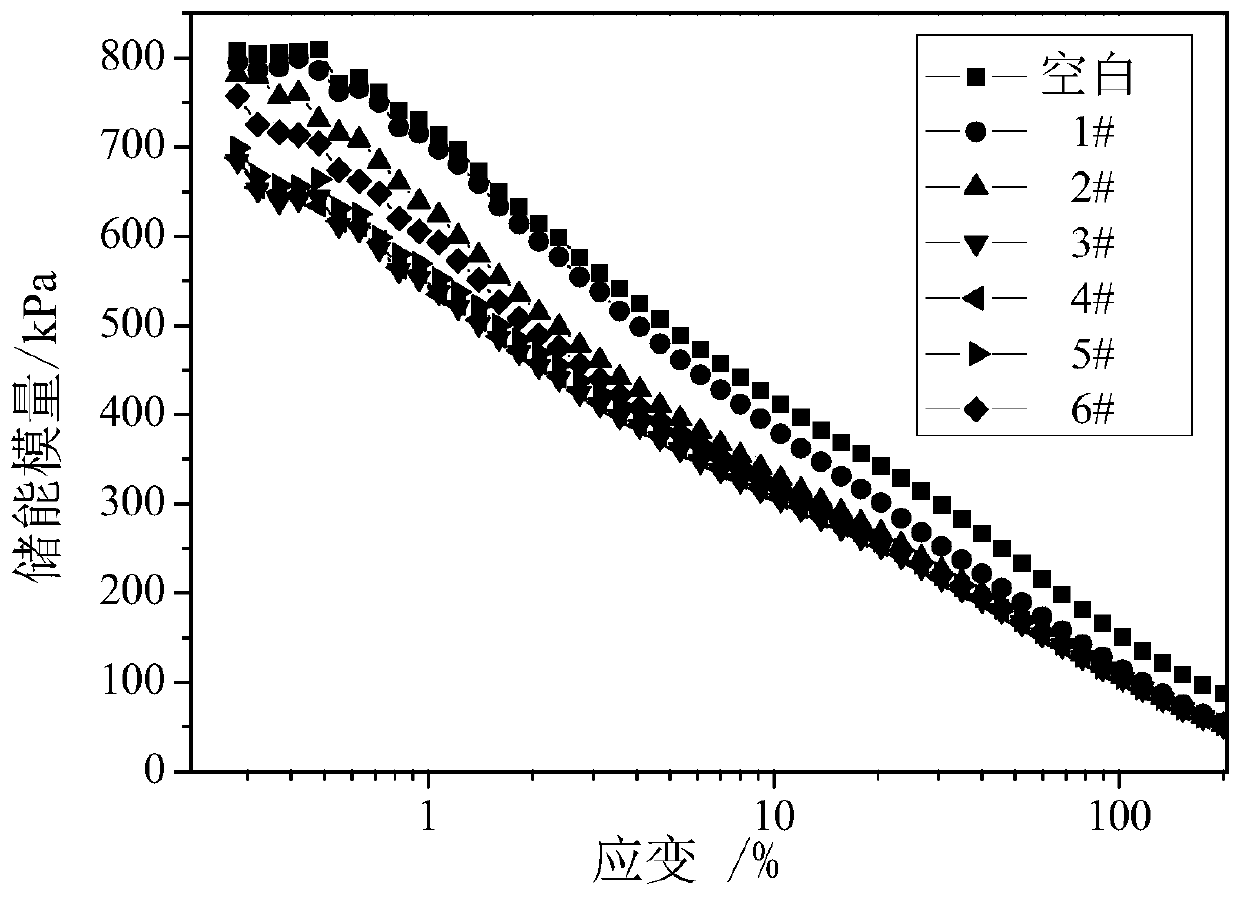

A technology of functional additives and reinforcing fillers, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve problems such as affecting the coupling agent and rubber bonding, high Mooney viscosity of mixed rubber, and easy rebound of Mooney viscosity, etc. Achieve the effect of improving dispersion, balancing wet skid resistance and rolling resistance, and reducing Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Put 20 parts by mass of octadecylamine into the reactor, heat up to complete melting, then slowly add the above-mentioned substances to 30 parts by mass of white carbon black 175GR at the same temperature, stir quickly, and then continue to add 8 parts by mass of zinc oxide and 42 parts by mass Parts of glycerin and continue to stir until the powder state, namely the reinforcing filler functional additive 1#.

Embodiment 2

[0060] Put 28 parts by mass of octadecylamine, 60 parts by mass of glycerol stearate and 12 parts by mass of zinc oxide into the reaction vessel, heat up and stir until completely melted, then pour out and cool to make tablets or melt granulate to obtain the reinforcing filler Functional additive 2#.

Embodiment 3

[0062] Put 22 parts by mass of oleic acid into the reaction vessel 1, heat up to 65°C, then put 3.3 parts by mass of zinc oxide into the reaction vessel, heat up to 125°C, and continue to drop 0.5 parts by mass of H 2 0, followed by vacuuming for about 10min, cooling to about 100°C for later use, then putting 7.98 parts by mass of glycerin, 7.02 parts by mass of zinc oxide and 0.2% salicylic acid into the reaction vessel 2, heating up to 200°C for 2.5h, centrifuging Wash and cool down, then add the sample prepared by reaction vessel 2, 23 parts by mass of octadecylamine, 26 parts by mass of stearyl alcohol and 10 parts by mass of glycerol stearate into reactor 1 and stir until completely melted, then pour out Cooling and tableting or melt granulation, the functional additive 3# for reinforcing filler is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com