Bimetal plunger pump cylinder body extrusion casting forming method

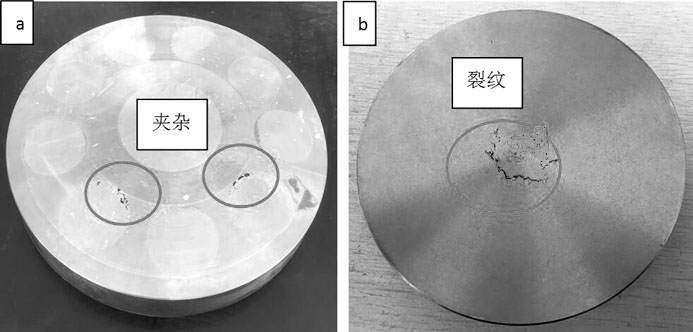

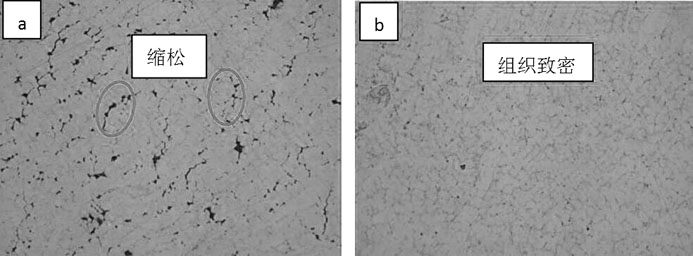

A technology of extrusion casting and forming method, which is applied in the field of bimetallic extrusion molding preparation, and can solve problems such as inclusions, large difference in thermal expansion coefficient, and low interface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

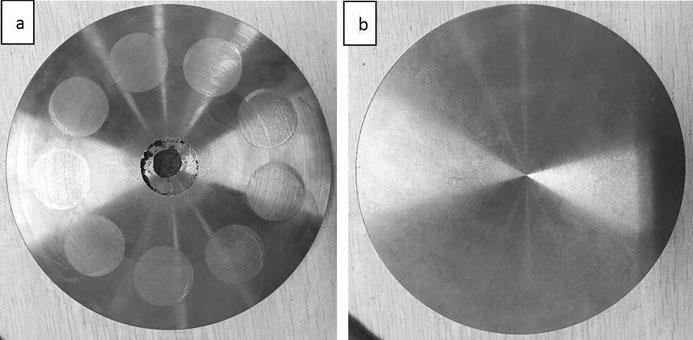

Examples

Embodiment 1

[0031] A method for die-casting the rotor of a steel-copper bimetallic plunger pump, using such as Figure 8 The squeeze casting mold shown is carried out, which specifically includes the following steps:

[0032] 1) Pretreatment of the steel matrix: The steel matrix is cleaned by alkali and acid ultrasonic waves (cleaning time 10min, solution concentration 10%) to obtain a steel matrix blank.

[0033] 2) Smelting: put the lead-tin-bronze alloy into the melting furnace according to the composition ratio for smelting.

[0034] 3) Preheating: Put the steel matrix obtained in the above step 1 into the extrusion die, preheat the steel matrix through the eddy current generated by the electromagnetic coil, and measure the temperature of the inner and outer surfaces of the steel matrix by an infrared thermometer. The preheating temperature is 1150°C. After the preset temperature is reached, the liquid copper alloy at 1200°C is injected into the steel matrix, and it is cooled to 76...

Embodiment 2

[0038] A method for die-casting the rotor of a steel-copper bimetallic plunger pump, using such as Figure 8 The squeeze casting mold shown is carried out, which specifically includes the following steps:

[0039] 1) Pretreatment of the steel matrix: The steel matrix is cleaned by alkali and acid ultrasonic waves (cleaning time 10min, solution concentration 10%) to obtain a steel matrix blank.

[0040] 2) Smelting: put the lead-tin-bronze alloy into the melting furnace according to the composition ratio for smelting.

[0041] 3) Preheating: Put the steel matrix obtained in the above step 1 into the extrusion die, preheat the steel matrix through the eddy current generated by the electromagnetic coil, and measure the temperature of the inner and outer surfaces of the steel matrix by an infrared thermometer. The preheating temperature is 1170°C. After the preset temperature is reached, the liquid copper alloy at 1250°C is injected into the steel matrix and cooled to 750°C at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com