500 MPa-grade high-strength anti-seismic structural steel and production method thereof

A technology of anti-seismic structure and production method, applied in the direction of metal rolling, etc., can solve the problems of high yield ratio, difficulty in guaranteeing strength, and inability to meet the anti-seismic requirements of high-rise steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A 500MPa-grade high-strength anti-seismic structural steel, the chemical composition of the steel is: C: 0.11%, Si: 0.22%, Mn: 1.18%, Alt: 0.038%, Nb: 0.012%, Ti: 0.016% , Ni: 0.16%, Cr: 0.43%, Mo: 0.26%, P: 0.011%, S: 0.0009%, the rest is Fe and unavoidable impurities;

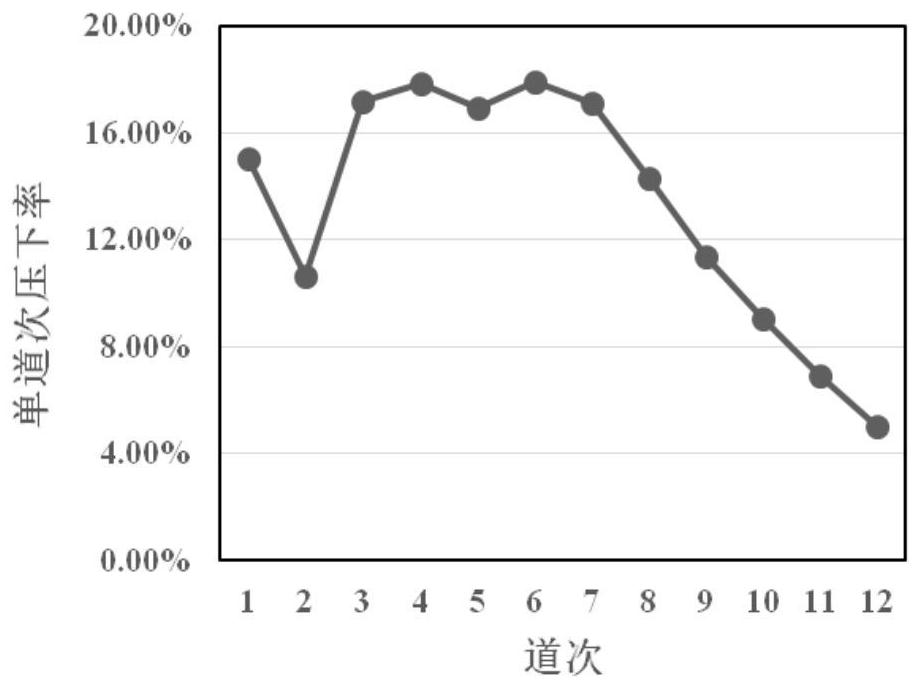

[0062] The preparation method provided above is used for preparation, and the important parameters in the preparation process are as follows: the size of the slab is 200*1850*2800 (mm), the size of the steel plate is 35*1980*13150 (mm), the compression ratio is 5.71, and the width ratio is 1.07. The center segregation of slab is C type 0.5. The heating temperature is 1151°C, the double-stand two-stage controlled rolling, the finishing rolling start temperature is 858°C, the final rolling temperature is 821°C, the waiting thickness is 70mm, the final cooling temperature is 590°C, and the cooling rate is 18°C / S.

Embodiment 2

[0064] A 500MPa grade high-strength anti-seismic structural steel, the chemical composition of the steel is: C: 0.12%, Si: 0.25%, Mn: 1.15%, Alt: 0.035%, Nb: 0.010%, Ti: 0.014%, Ni : 0.15%, Cr: 0.46%, Mo: 0.27%, P: 0.010%, S: 0.001%, the rest is Fe and unavoidable impurities,

[0065] The preparation method provided above is used for preparation, and the important parameters in the preparation process are as follows: the size of the slab is 250*1850*3550 (mm), the size of the steel plate is 50*2820*10090 (mm), the compression ratio is 5.0, and the width ratio is 1.53. The center segregation of slab is C type 0.5. The heating temperature is 1160°C, the double-stand two-stage controlled rolling, the finishing rolling start temperature is 840°C, the final rolling temperature is 801°C, the waiting thickness is 100mm, the final cooling temperature is 565°C, and the cooling rate is 13°C / S.

experiment example

[0067] Example 1-2 and 5 batches were randomly selected for performance testing, and the test results are shown in the table below.

[0068]

[0069]

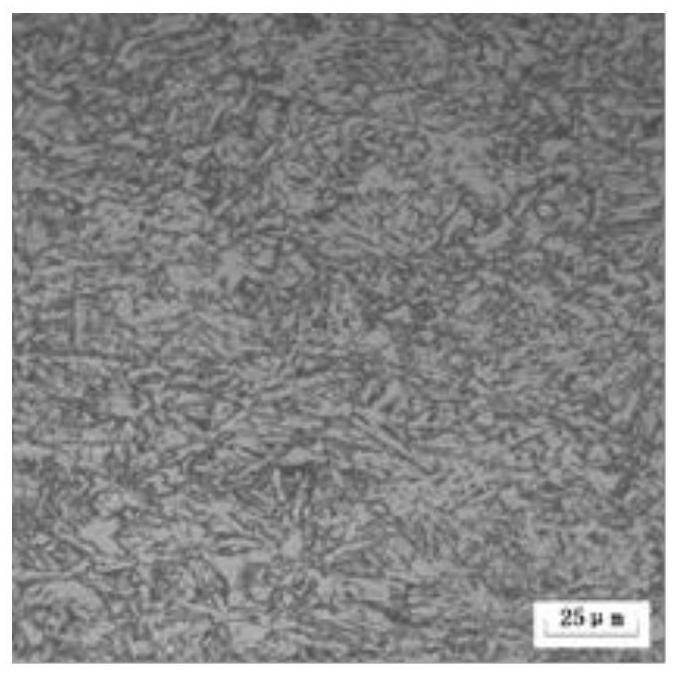

[0070] It can be obtained from the examples and sampling data that the structural steel is prepared by adopting the formula and process provided by the implementation of the present invention, which realizes narrow strength fluctuation control, greatly reduces the yield ratio, and improves the Z-direction performance of the steel plate. High strength and good shock resistance at the same time, the yield strength of the prepared structural steel is ≥520-580 (MPa), the tensile strength is ≥660-720 (MPa), the yield ratio is ≤0.82, and the average impact energy at -20°C is ≥ 180J, Z direction average value ≥60%.

[0071] One or more technical solutions in the embodiments of the present invention also have at least the following technical effects or advantages:

[0072] (1) The structural steel ratio provided by the embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com