Nano ceramic material modified latex paint and preparation method thereof

A nano-ceramic and nano-ceramic powder technology is applied in the field of nano-ceramic material modified latex paint and its preparation, which can solve the problem of acid and alkali resistance of latex paint, poor corrosion resistance, unstable coating product quality, poor adhesion of building walls, etc. problem, to achieve the effect of stable latex paint system, excellent acid and alkali corrosion resistance, and small performance difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

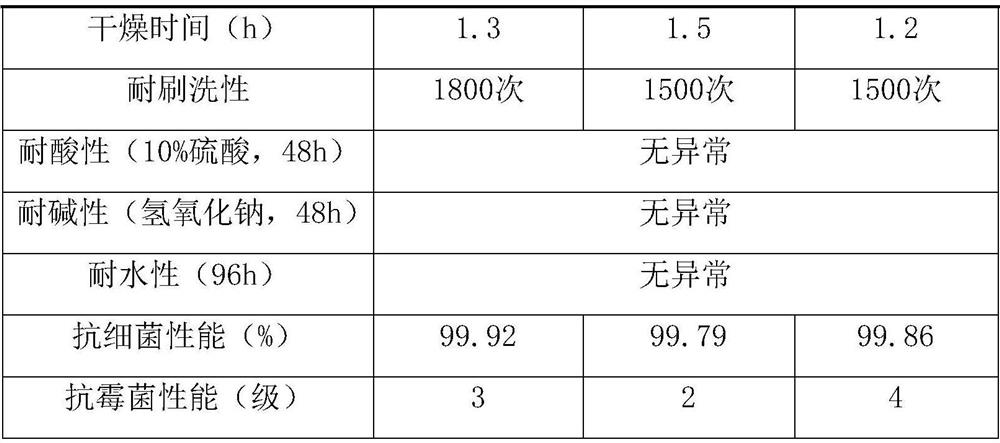

Embodiment 1

[0027] In this embodiment, the nano-ceramic material modified latex paint includes the following components: 320g of nano-ceramic powder, 30g of multifunctional amine auxiliary agent, 100g of hollow microspheres, 1200g of silicon-acrylic emulsion, 80g of film-forming auxiliary agent, 500g of pigment and filler, antibacterial Agent 20g, defoamer 30g, thickener 20g, dispersant 30g, water 690g.

[0028] Among them, the nano-ceramic powder is nano-alumina ceramic powder, and the particle size of the nano-ceramic powder is 20-60nm; the multifunctional amine additive is AMP-95; The membrane aid is a mixture of diethylene glycol monomethyl ether and propylene glycol; the defoamer is isopropanol; the thickener is hydroxyethyl cellulose; the dispersant is polyethylene glycol; the antibacterial agent is o-phenylphenol ; The pigment and filler are rutile titanium dioxide.

[0029] The preparation method of above-mentioned nano-ceramic material modified latex paint, such as figure 1 sho...

Embodiment 2

[0035] In the present embodiment, nano-ceramic material modified latex paint comprises the following components: 200g of nano-ceramic powder, 40g of multifunctional amine auxiliary agent, 150g of hollow microspheres, 1000g of pure acrylic emulsion, 60g of film-forming auxiliary agent, 420g of pigment and filler, antibacterial Agent 10g, defoamer 20g, thickener 30g, dispersant 20g, water 600g.

[0036] Wherein, the nano-ceramic powder is a mixture of nano-alumina ceramic powder and nano-titanium dioxide ceramic powder, and the particle size of the nano-ceramic powder is 20-60nm.

[0037] All the other components are the same as in Example 1.

[0038] The preparation method of above-mentioned nano ceramic material modified latex paint, comprises the following steps:

[0039] S1. Mix water, defoamer, dispersant, pigments and fillers, and multifunctional amine additives uniformly at room temperature through medium-speed stirring to obtain the first mixture. The stirring speed is ...

Embodiment 3

[0044] In the present embodiment, nano-ceramic material modified latex paint comprises the following components: 400g of nano-ceramic powder, 50g of multifunctional amine auxiliary agent, 80g of hollow microspheres, 1120g of silicon-acrylic emulsion, 100g of film-forming auxiliary agent, 300g of pigment and filler, antibacterial Agent 30g, defoamer 10g, thickener 10g, dispersant 50g, water 800g.

[0045] Wherein, the nano-ceramic powder is nano-titanium dioxide ceramic powder, and the particle size of the nano-ceramic powder is 20-60nm.

[0046] All the other components are the same as in Example 1.

[0047] The preparation method of above-mentioned nano ceramic material modified latex paint, comprises the following steps:

[0048] S1. Mix water, defoamer, dispersant, pigments and fillers, and multifunctional amine additives at room temperature through medium-speed stirring to obtain the first mixture. The stirring speed is controlled to 900r / min, and the stirring time is 20min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com