Dual-sealing flange

A double sealing and flange technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem of small stress concentration factor, etc., achieve good use conditions, increase service life, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

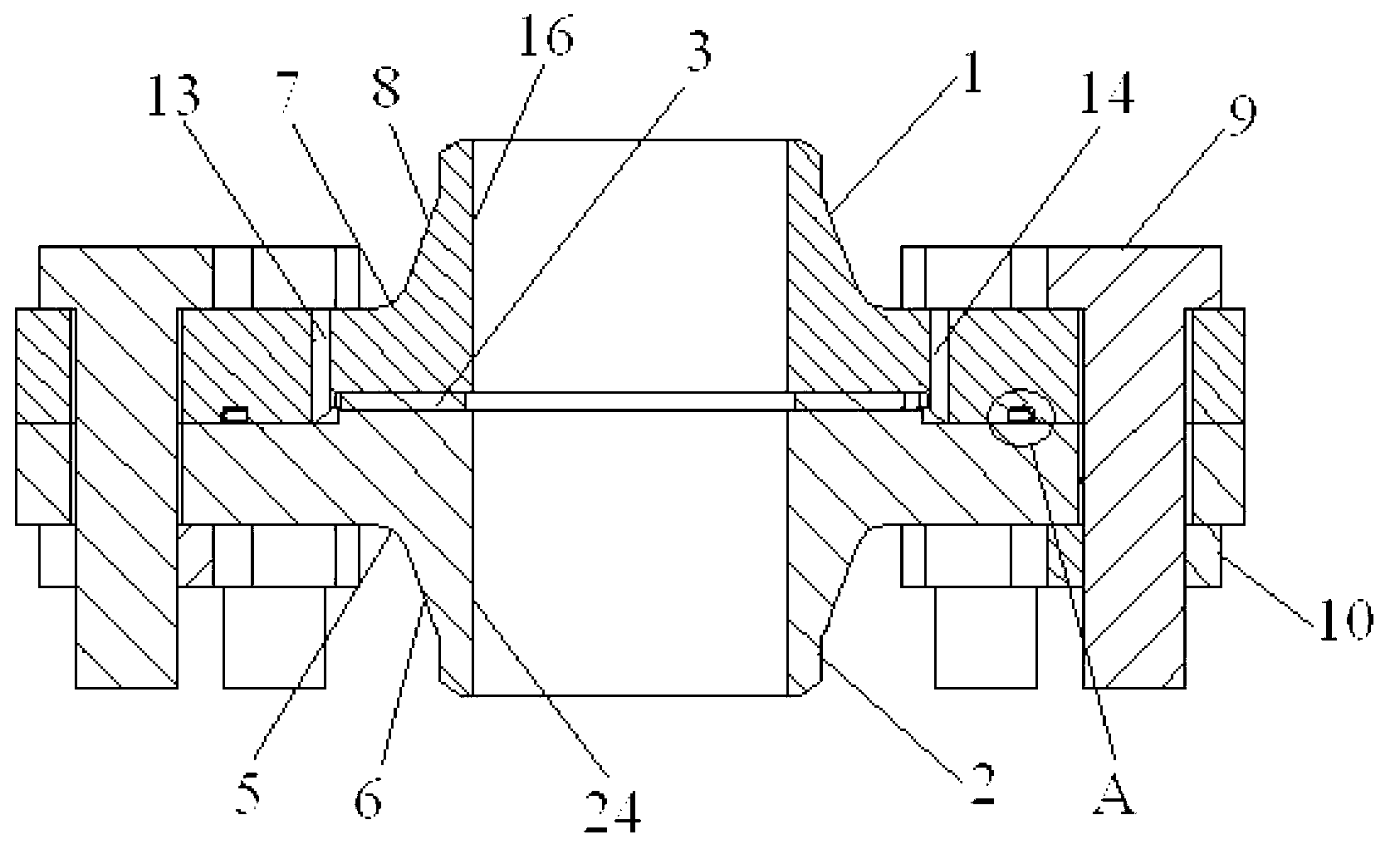

[0025] see Figure 1 to Figure 6 , the present invention, that is, a double sealing flange, which includes a female flange 1, a male flange 2, a graphite wound gasket 3 and a metal C-shaped sealing ring 4, wherein:

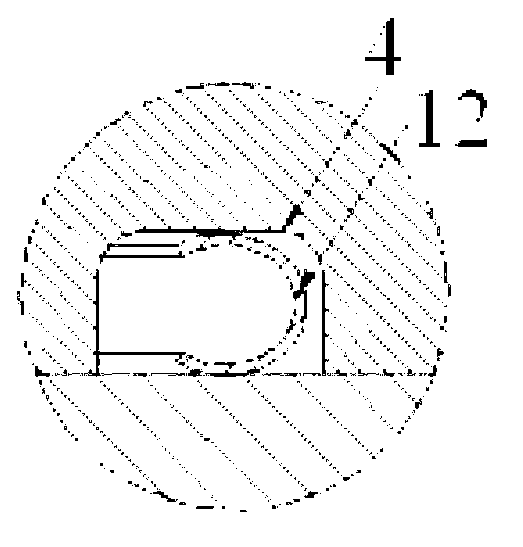

[0026] The center of one end face of the female flange 1 is provided with a groove 11, and a groove 12 is provided around the groove 11 on the end face, and an air intake passage is symmetrically provided between the groove 11 and the groove 12 on the end face. A hole 13 and an air outlet through hole 14, the air inlet through hole 13 and the air outlet through hole 14 communicate with the groove 11 through a protective gas channel 15 respectively;

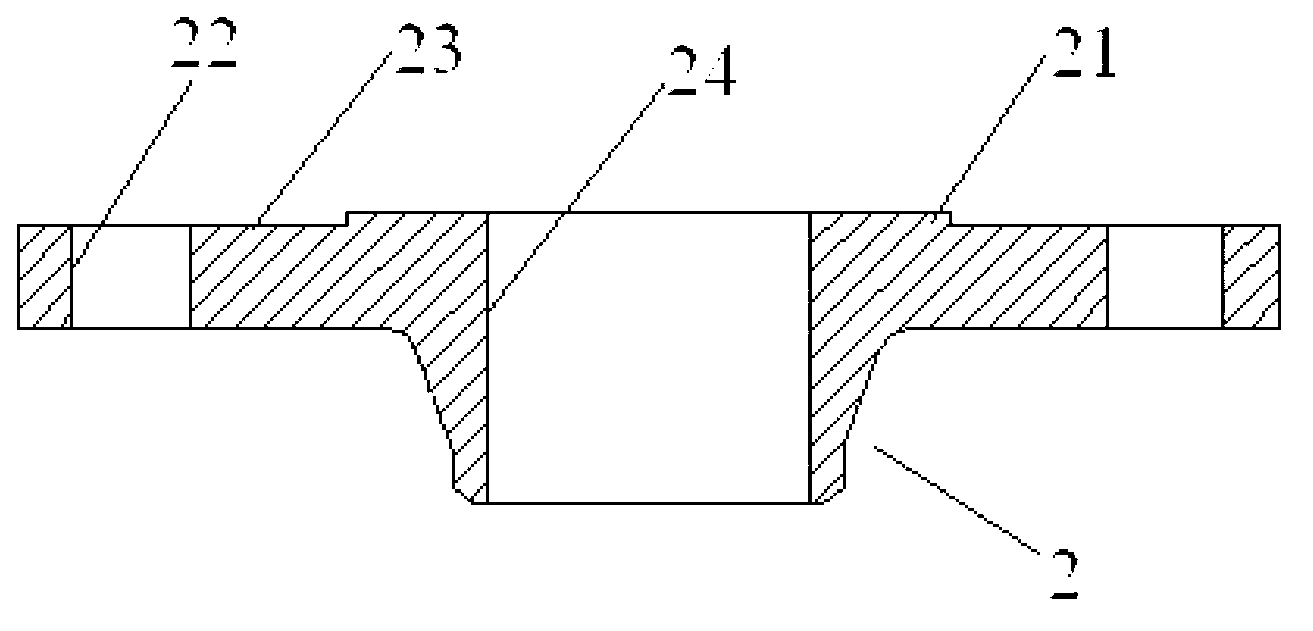

[0027] The center of one end surface of the male flange 2 is provided with a boss 21 matching the groove 11;

[0028] The graphite wound gasket 3 is arranged in the groove 11, and the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com