Method for preparing RG-I pectic polysaccharide rich in arabinose side chains

A pectin polysaccharide, RG-I technology, applied in the field of pectin extraction, can solve the problems of insufficient source of RG-I pectin raw materials, complex extraction process, small storage capacity, etc., to achieve low cost, simple process, and short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

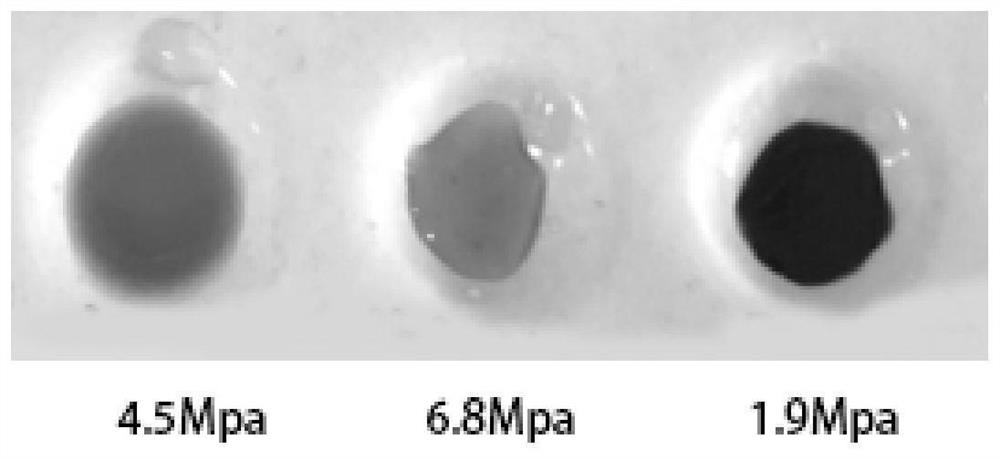

Embodiment 1

[0050] Peanut wet residue was provided by a peanut oil processing factory in Jiangsu and kept frozen. Take 1kg of wet-based material, add 1.8L of deionized water, melt, stir evenly, adjust the pH of the whole system to 5.0 with 20% citric acid solution, place it in a high-pressure reactor at 100°C, fill it with nitrogen, stir, and adjust the system pressure 5.0Mpa, react for 40min. After the reaction is finished, cool to room temperature, centrifuge at 9000rpm for 15min to obtain the supernatant, and use a 100,000 Dalton ultrafiltration membrane to conduct ultrafiltration separation of the above crude extract at a temperature of 35°C and a pressure of 15Psi for constant volume ultrafiltration, and the retentate Freeze-dried to obtain 25g of refined peanut residue RG-I pectin polysaccharide, the yield of this component reached 37.87%, and the purity of RG-I was 90%.

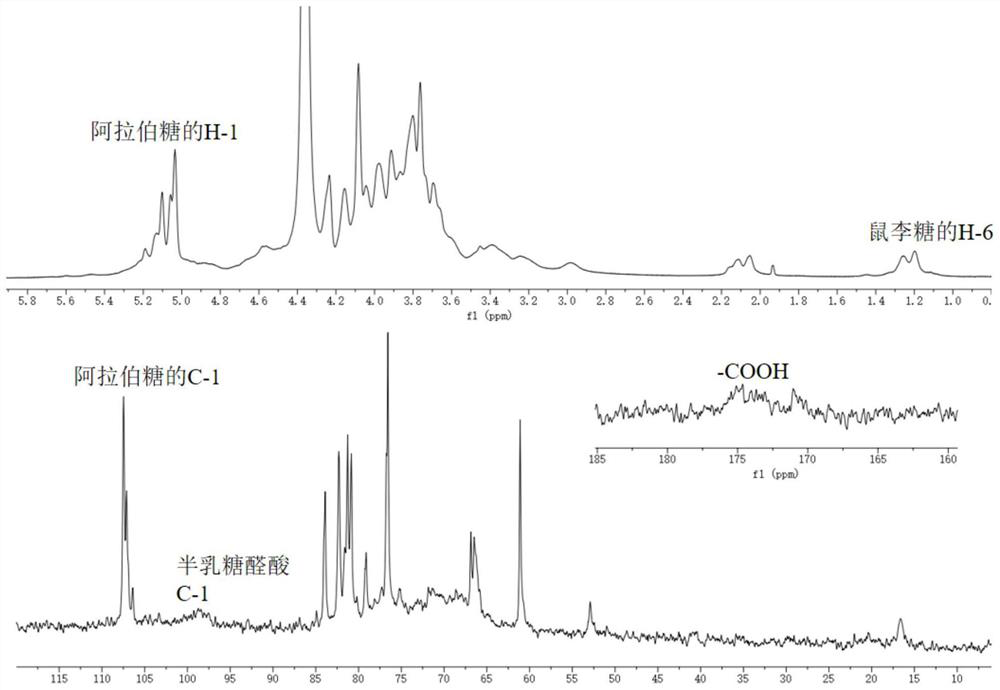

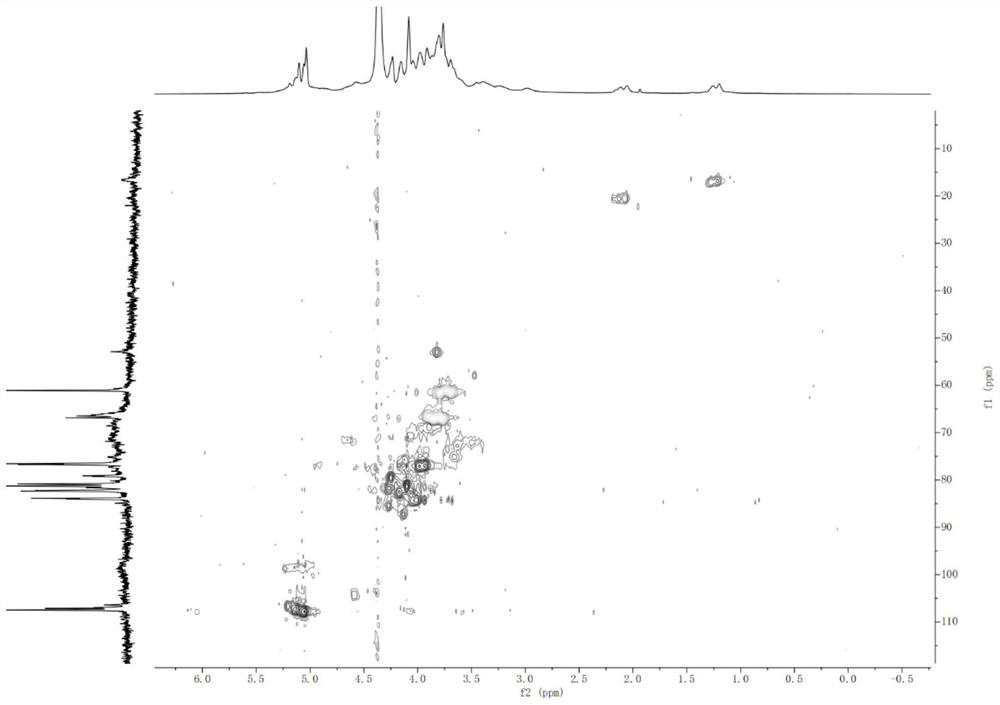

[0051] Pectin monosaccharide composition analysis was performed by high performance anion exchange chromatogra...

Embodiment 2

[0060] Peanut wet residue was provided by a peanut oil processing factory in Jiangsu and kept frozen. Take 2kg and add 3.6L deionized water, stir evenly, adjust the pH of the whole system to 3.9 with 20% citric acid solution, heat to 95°C, fill with nitrogen to keep the pressure at 5.5Mpa, and react for 40min. After the reaction is completed, cool to room temperature, centrifuge at 9000rpm for 15min, and obtain the supernatant. A 100,000 Dalton ultrafiltration membrane was used to conduct ultrafiltration and separation of the above crude extract at a temperature of 35° C. and a pressure of 20 Psi for constant volume ultrafiltration. The retentate was freeze-dried to obtain 66 g of refined peanut residue RG-I pectin polysaccharide. The yield of this component reaches 34.9%, and the purity of RG-I is 92.5%.

[0061] Determination of peanut pomace pectin polysaccharide according to the high-efficiency anion-exchange chromatography described above, its composition is as follows:...

Embodiment 3

[0068] Peanut wet residue was provided by a peanut oil processing factory in Jiangsu and kept frozen. Take 2.5kg of wet-based material, add 4.5L of deionized water, stir evenly, adjust the pH of the whole system to 4.5 with 20% citric acid solution, and then place it in a high-pressure reactor at 105°C

[0069] , filled with nitrogen, pressure 6.0Mpa, reaction 40min. After the reaction was completed, cool to room temperature, centrifuge at 9000rpm for 15min to obtain the supernatant, and use a 100,000 Dalton ultrafiltration membrane to conduct ultrafiltration separation of the above crude extract at a temperature of 35°C and a pressure of 25Psi for constant volume ultrafiltration. The retentate was freeze-dried to obtain 89 g of refined peanut residue RG-I pectin polysaccharide. The yield of this component relative to the dry basis reaches 30.2%, and the purity reaches 95.3%.

[0070] Determination of peanut pomace pectin polysaccharide according to the high-efficiency anion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com