A preparation method and quality detection method of composite spherical particles for adsorption and removal of active phosphate in organic solvent

A technology of spherical particles and organic solvents, applied in the chemical industry, can solve problems such as catalyst poisoning and deactivation, and achieve the effects of promoting adsorption capacity, improving adsorption capacity, and increasing adsorption surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

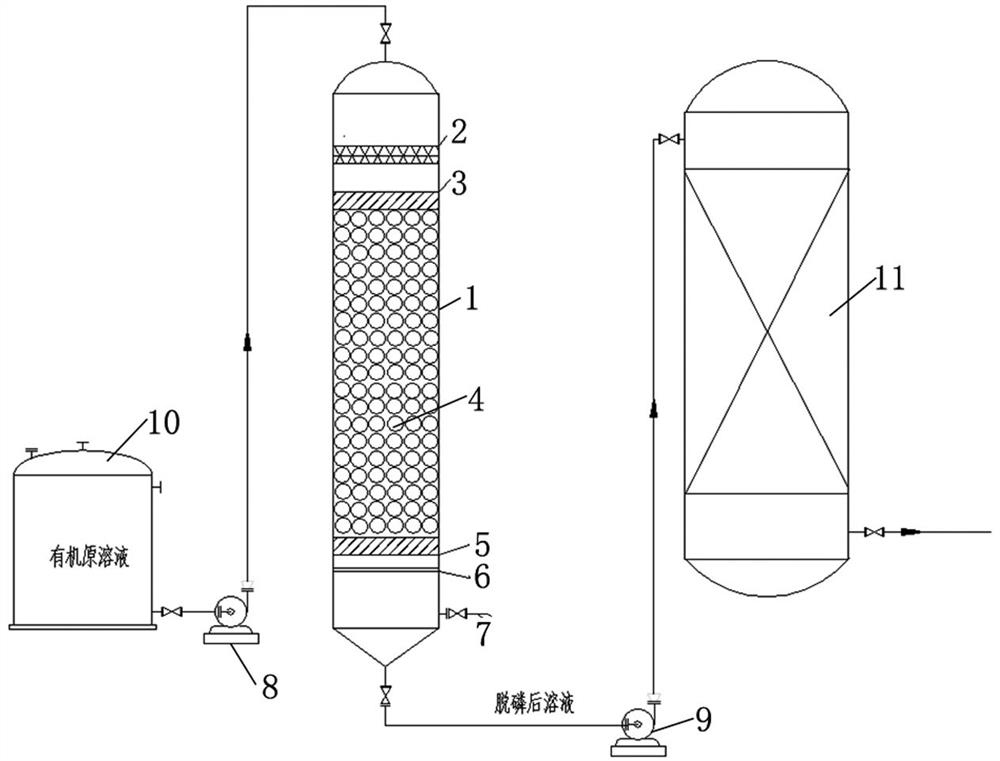

Image

Examples

Embodiment 1

[0033] Embodiment 1, a preparation method of composite spherical particles for adsorption and removal of active phosphates in organic solvents.

[0034] a) Raw material activation:

[0035] Pulverize the clay and pass it through a 100-mesh sieve, pass the industrial diatomite powder through a 150mm sieve, take the material under the sieve, weigh 900g of the clay powder and 600g of the diatomite powder and mix thoroughly, soak in 4000mL of 1mol / L hydrochloric acid solution, and ultrasonically acidify for 1 ~2h, negative pressure filtration and washing with ultrapure water to neutrality. It was dried at 120 °C, then placed in a muffle furnace, calcined at 700 °C for 5 h, taken out and cooled to room temperature, and ground through a 150-mesh sieve to obtain activated powder.

[0036] b) Impregnation modification:

[0037] Weigh 1000g of the activated mixed powder, put it in 2500g of 3mol / L calcium nitrate solution, mix it thoroughly, conduct magnetic stirring, supersaturate im...

Embodiment 2

[0046] Embodiment 2, a preparation method of composite spherical particles for adsorption and removal of active phosphates in organic solvents.

[0047] Compared with Example 1, the difference is that the concentration of the calcium nitrate solution in the step b) is changed to 5mol / L, the immersion time is changed to 18h, and other conditions are the same as those of Example 1. The effect of impregnant concentration on the adsorption capacity of spherical particles was mainly investigated.

Embodiment 3

[0048] Embodiment 3, a preparation method of composite spherical particles for adsorption and removal of active phosphates in organic solvents.

[0049] Compared with Example 1, the difference is that the calcium nitrate solution in the step b) replaces the calcium chloride solution. Other conditions are the same as in Example 1. The effect of the type of impregnating agent on the adsorption capacity of spherical particles was mainly investigated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com