Concrete filled steel tubular column reinforcing method based on fiber woven mesh

A technology of steel tube concrete columns and fiber woven mesh, which is applied in building maintenance, construction, climate change adaptation, etc., can solve problems such as degradation of bearing capacity, and achieve the effects of improving strength, delaying local buckling, and excellent impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

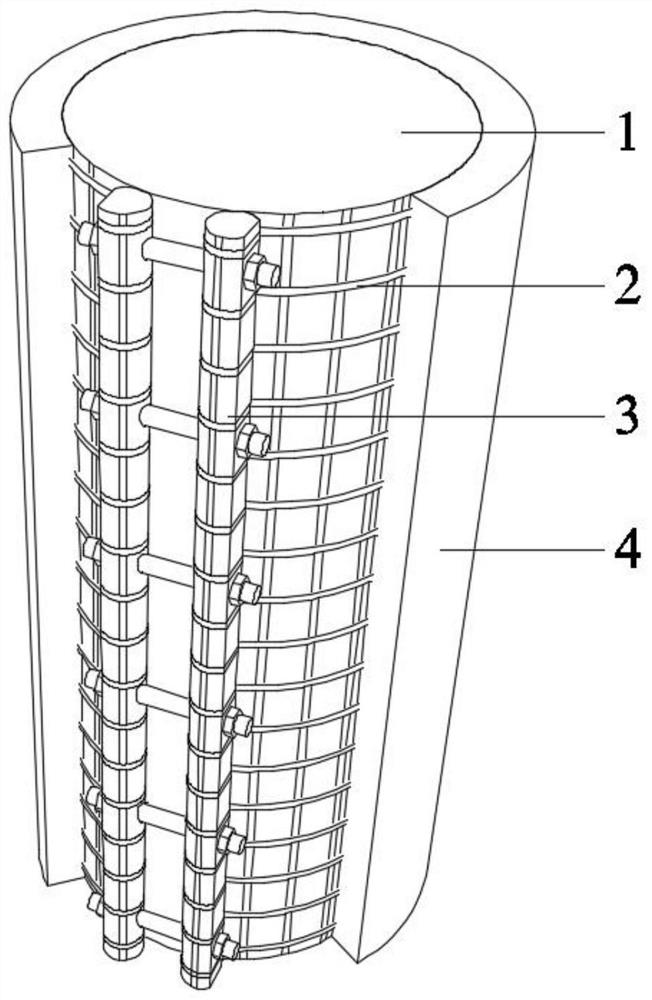

Image

Examples

Embodiment 1

[0038] The type of braided mesh is bidirectional carbon fiber braided mesh, the prestress level is 30%, the mesh size is 20mm×20mm, the thickness of single bundle fiber is 0.5mm, the width is 1mm, the tensile strength of carbon fiber is 3400MPa, and the ultimate elongation rate is 1.5 %; The cutting circle radius of the metal rod in the tension anchor is 12mm, the arc angle is 270°, and the screw diameter is 12mm; the thickness of the early strength ECC layer is 30mm, and its composition is composed of sulphoaluminate cement, first-grade fly ash , water, fine sand, water reducing agent, early strength agent, PVA fiber, the corresponding specific gravity is sulphoaluminate cement: primary fly ash: water: fine sand: water reducing agent: early strength agent: PVA fiber = 1 :0.2: 0.4: 1: 0.005: 0.0005: 0.015, the early strength agent is lithium carbonate, the early strength ECC has a compressive strength of more than 30MPa within 6 hours, and the ultimate tensile strain is more th...

Embodiment 2

[0040]The type of woven mesh is unidirectional carbon fiber woven mesh, the prestress level is 30%, the mesh size is 10mm×10mm, the thickness of single bundle fiber is 0.5mm, the width is 0.5mm, the tensile strength of carbon fiber is 3400MPa, and the ultimate elongation 1.5%; the cutting circle radius of the metal rod in the tension anchor is 10mm, the arc angle is 240°, and the screw diameter is 10mm; the thickness of the early-strength ECC layer is 35mm, and its composition is composed of sulphoaluminate cement, first-grade powder Composition of coal ash, water, fine sand, water reducer, early strength agent, PVA fiber, the corresponding specific gravity is sulphoaluminate cement: primary fly ash: water: fine sand: water reducer: early strength agent: PVA fiber =1:0.25:0.5:0.8:0.003:0.0002:0.02, the early-strength agent is lithium carbonate, the early-strength ECC has a compressive strength of more than 30MPa within 12 hours, and an ultimate tensile strain of more than 2%. ...

Embodiment 3

[0042] The type of braided net is two-way basalt fiber braided net, the prestress level is 30%, the grid size is 10mm×10mm, the thickness of single bundle fiber is 1mm, the width is 2mm, the tensile strength of basalt fiber is 600MPa, and the ultimate elongation is 2.2%; the cutting circle radius of the metal rod in the tension anchor is 12mm, the arc angle is 270°, and the screw diameter is 14mm; the thickness of the early strength ECC layer is 40mm, and its composition is composed of sulphoaluminate cement, first-grade pulverized coal Composed of ash, water, fine sand, water reducer, early strength agent, and PVA fiber, the corresponding specific gravity is sulphoaluminate cement: primary fly ash: water: fine sand: water reducer: early strength agent: PVA fiber = 1: 0.1: 0.45: 0.8: 0.006: 0.001: 0.02, the early strength agent is lithium carbonate, the early strength ECC can achieve a compressive strength of more than 30MPa within 4 hours, and the ultimate tensile strain is mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com