Quantum dot and surface modification method thereof, and quantum dot light-emitting diode

A quantum dot luminescence and surface modification technology, applied in luminescent materials, chemical instruments and methods, nano optics, etc., can solve the problems of quantum dot fluorescence efficiency reduction, precipitation, quantum dot aggregation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

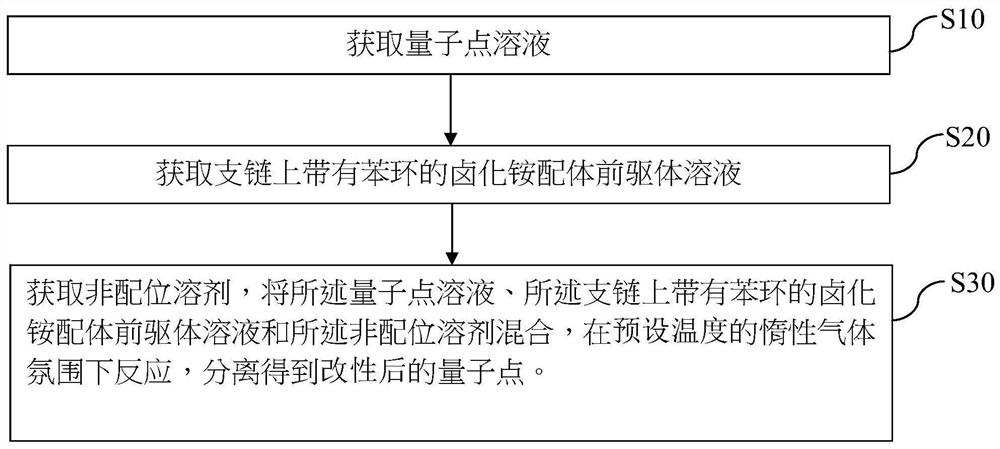

Method used

Image

Examples

Embodiment 1

[0065] A CdSe / CdS quantum dot with surface-grafted benzethonium chloride ligand, comprising the following preparation steps:

[0066] S10. Preparation of quantum dot solution: at room temperature, dissolve 300 mg of CdSe / CdS quantum dots (surface ligand is oleic acid) with 10 ml of n-hexane to obtain a CdSe / CdS quantum dot solution.

[0067] S20. Prepare a ligand solution: at room temperature, mix 50 mg of benzethonium chloride with 20 ml of chloroform, and place at 50° C. for reflux heating until completely dissolved to obtain a benzethonium chloride ligand solution.

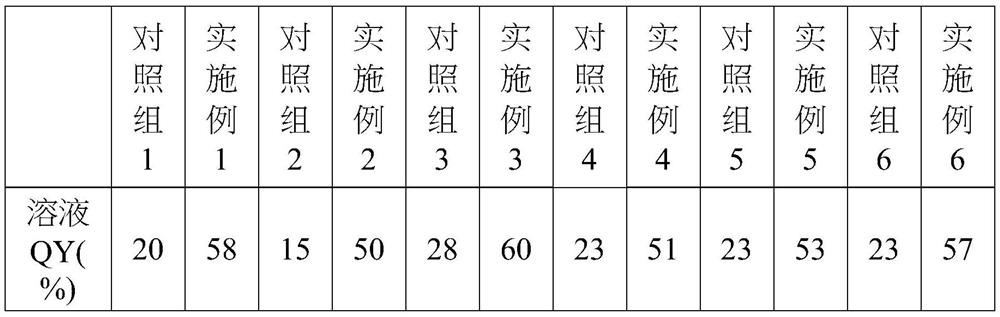

[0068] S30. In an argon gas atmosphere, at 150 ° C, after mixing the CdSe / CdS quantum dot solution, the benzethonium chloride ligand solution and 60 ml of octadecene, the reaction was performed for 10 minutes, and after separation, n-hexane and ethanol were used to repeatedly dissolve, After precipitation and centrifugation, quantum dots with benzethonium chloride ligands grafted on the surface are obtained aft...

Embodiment 2

[0070] A kind of InP / ZnSeS quantum dot with surface-grafted benzethonium chloride ligand, comprising the following preparation steps:

[0071] S10. Preparation of quantum dot solution: at room temperature, dissolve 300 mg of InP / ZnSeS quantum dots (surface ligand is oleic acid) with 10 ml of n-hexane to obtain an InP / ZnSeS quantum dot solution.

[0072] S20. Prepare a ligand solution: at room temperature, mix 50 mg of benzethonium chloride with 20 ml of chloroform, and place at 50° C. for reflux heating until completely dissolved to obtain a benzethonium chloride ligand solution.

[0073] S30. In an argon gas atmosphere, at 150 ° C, after mixing the InP / ZnSeS quantum dot solution, the benzethonium chloride ligand solution and 60 ml of octadecene, the reaction was performed for 10 minutes, and after separation, n-hexane and ethanol were used to repeatedly dissolve, After precipitation and centrifugation, InP / ZnSeS quantum dots with surface grafted benzethonium chloride ligands ...

Embodiment 3

[0075] A CdZnS / ZnS quantum dot with surface-grafted benzethonium chloride ligand, comprising the following preparation steps:

[0076] S10. Preparation of quantum dot solution: at room temperature, dissolve 300 mg of CdZnS / ZnS quantum dots (surface ligand is oleic acid) with 10 ml of n-hexane to obtain a CdZnS / ZnS quantum dot solution.

[0077] S20. Prepare a ligand solution: at room temperature, mix 50 mg of benzethonium chloride with 20 ml of chloroform, and place at 50° C. for reflux heating until completely dissolved to obtain a benzethonium chloride ligand solution.

[0078] S30. In an argon gas atmosphere, at 150 ° C, after mixing the CdZnS / ZnS quantum dot solution, the benzethonium chloride ligand solution and 60 ml of octadecene, react for 10 minutes, and after separation, use n-hexane and ethanol to repeatedly dissolve, After precipitation and centrifugation, CdZnS / ZnS quantum dots with benzethonium chloride ligands grafted on the surface were obtained after purificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com