Water-based nano composite heat preservation and insulation coating and preparation method thereof

A nanocomposite, thermal insulation technology, applied in the direction of reflective/signal coatings, coatings, etc., can solve the problems of increased cost, cumbersome construction, and poor thermal insulation effect, achieving high thermal insulation rate, improved reflective thermal insulation and The effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

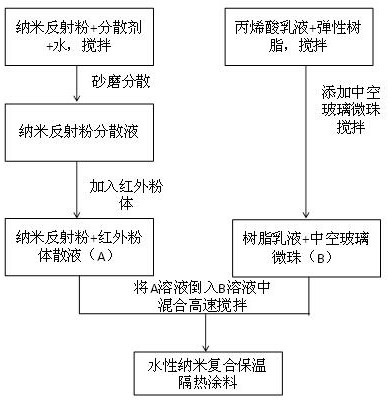

Method used

Image

Examples

Embodiment 1

[0022] In Example 1, a water-based nano-composite thermal insulation coating is composed of the following raw materials in parts by weight: 12 parts of nano-reflective powder (Japanese Ishihara titanium dioxide CR-90, primary particle size is 210nm), 0.8 parts of dispersant (Lubo Run 20000), 8 parts of water, 4 parts of infrared powder, 30 parts of acrylic emulsion, 12 parts of elastic resin and 12 parts of hollow glass microspheres.

[0023] Further, the nano reflective powder is a mixture of one or more of titanium dioxide, zinc oxide, and calcium carbonate, and the infrared powder is tremolite powder.

[0024] Further, the primary particle size of the nano reflective powder is between 10-1000 nm, and the particle size of the infrared powder is 5-50 microns.

[0025] Further, the solid content of the acrylic emulsion is 45%, the elastic resin is a polyurethane aqueous emulsion, and the solid content of the polyurethane aqueous emulsion is 50%.

[0026] Further, 0.2 parts of...

Embodiment 2

[0031] In Example 2, a water-based nano-composite thermal insulation coating is composed of the following raw materials in parts by weight: 18 parts of nano-reflective powder (Jingrui Xuancheng VK-JE01, the primary particle size is 50nm), 1.2 parts of dispersant (BYK180 ), 12 parts of water, 14 parts of infrared powder, 40 parts of acrylic emulsion, 16 parts of elastic resin and 18 parts of hollow glass microspheres.

[0032] Further, the nano reflective powder is a mixture of one or more of titanium dioxide, zinc oxide, and calcium carbonate, and the infrared powder is tremolite powder.

[0033] Further, the primary particle size of the nano reflective powder is between 10-1000 nm, and the particle size of the infrared powder is 5-50 microns.

[0034] Further, the solid content of the acrylic emulsion is 45%, the elastic resin is a polyurethane aqueous emulsion, and the solid content of the polyurethane aqueous emulsion is 50%.

[0035] Further, 0.4 parts of defoaming agent,...

Embodiment 3

[0040] In Example 3, a water-based nanocomposite thermal insulation coating is composed of the following raw materials in parts by weight: 15 parts of nano reflective powder, 1 part of dispersant (BYK180), 10 parts of water, 8 parts of infrared powder, 35 parts of acrylic emulsion 15 parts, 15 parts of elastic resin and 15 parts of hollow glass microspheres.

[0041] Further, the nano reflective powder is a mixture of one or more of titanium dioxide, zinc oxide, and calcium carbonate, and the infrared powder is tremolite powder.

[0042] Further, the primary particle size of the nano reflective powder is between 10-1000 nm, and the particle size of the infrared powder is 5-50 microns.

[0043] Further, the solid content of the acrylic emulsion is 45%, the elastic resin is a polyurethane aqueous emulsion, and the solid content of the polyurethane aqueous emulsion is 50%.

[0044] Further, 0.3 parts of defoaming agent, 0.2 parts of film forming agent, 0.3 parts of leveling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com