High-strength high-barrier fresh-keeping plastic film used for vegetable and fruit packaging and preparation method of plastic film

A plastic film, high barrier technology, applied in the field of packaging materials, can solve the problems affecting the service life and hand feel of the barrier material, the bonding strength of the composite layer is not high, and the mechanical properties are reduced, so as to achieve a simple and controllable preparation process scheme and improve the mechanical properties. and barrier properties, the effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

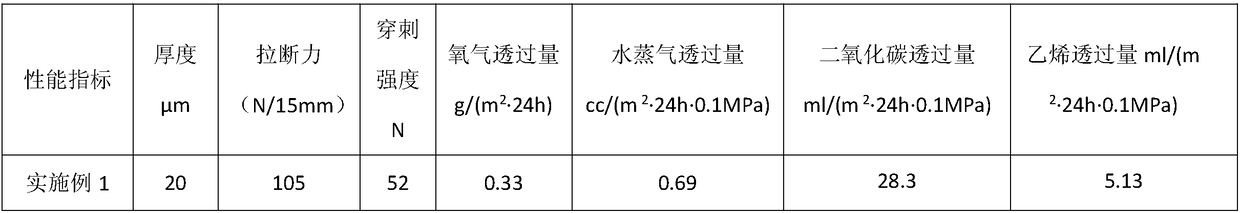

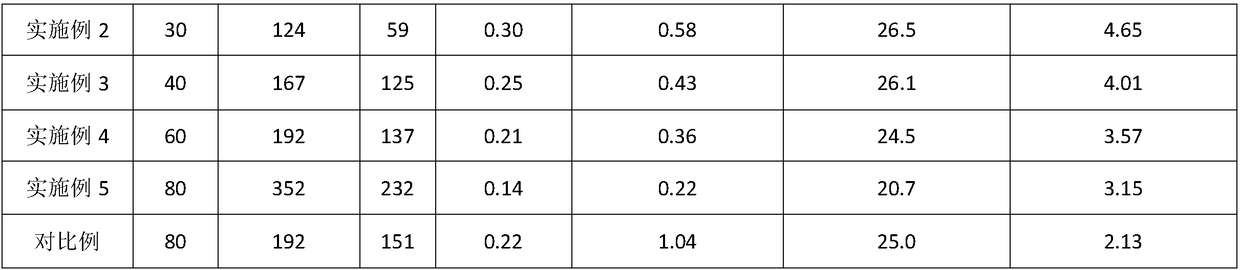

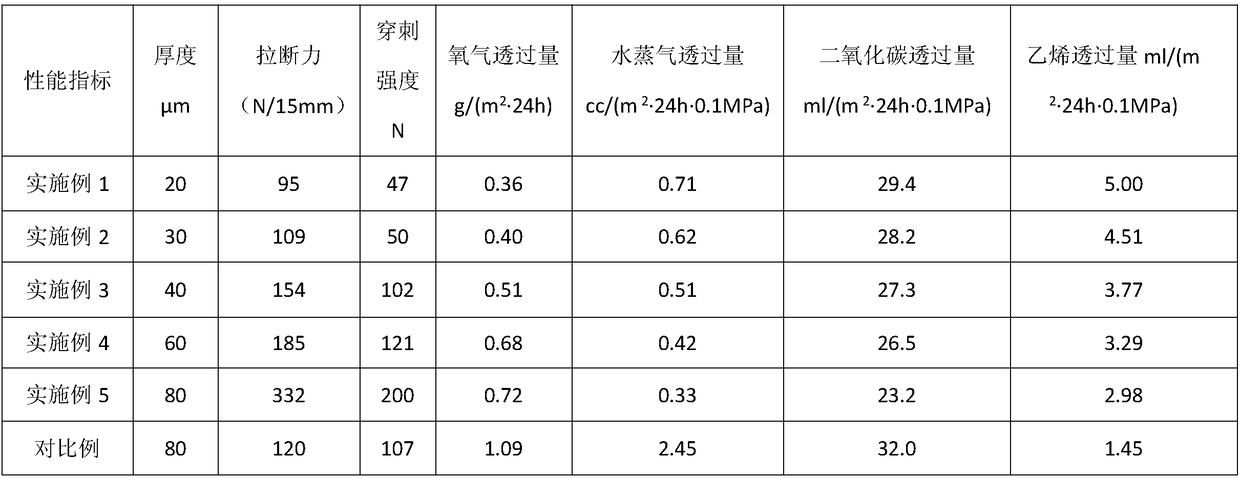

Examples

Embodiment 1

[0032] (1) According to the mass ratio of 1:0.5:20, the activated clay with a particle size of 3 μm, a radial size of 7 μm, and amphiphilic graphene oxide and styrene with a thickness of 0.5 nm are weighed;

[0033] (2) Add the amphiphilic graphene oxide into an organic solvent, disperse by ultrasonic, the ultrasonic power is 5kW, and the ultrasonic time is 30 minutes to obtain a uniform dispersion, then add activated clay, stir at high speed, and the speed of stirring at high speed is 1200rpm, The stirring time is 80 minutes, and the amphiphilic graphene oxide is uniformly wrapped with activated clay, and the viscosity is adjusted to obtain an activated clay / amphiphilic graphene oxide composite dispersion with a viscosity of 2.6 Pa·s;

[0034] (3) By the scraping method, the scraping rate is controlled to be 100nm / min, and the activated clay / amphiphilic graphene oxide composite dispersion is coated on the surface of a hyperbranched polyamide film substrate with a thickness of 10...

Embodiment 2

[0037] (1) According to the mass ratio of 1:1.3:25, the activated clay with a particle size of 10 μm, a radial size of 8 μm, and amphiphilic graphene oxide and perchlorethylene with a thickness of 1.3 nm are weighed;

[0038] (2) Add the amphiphilic graphene oxide into an organic solvent, disperse by ultrasonic, the ultrasonic power is 2.5kW, and the ultrasonic time is 35 minutes to obtain a uniform dispersion, then add activated clay, stir at a high speed, and the stirring rate at a high speed is 450rpm , the stirring time is 40 minutes, the amphiphilic graphene oxide is uniformly wrapped with activated clay, and the viscosity is adjusted to obtain an activated clay / amphiphilic graphene oxide composite dispersion with a viscosity of 2.8Pa·s;

[0039] (3) by the scraping method, control the scraping coating rate to be 300nm / min, the activated clay / amphiphilic graphene oxide composite dispersion is coated on the surface of the hyperbranched polyurethane film matrix with a thickn...

Embodiment 3

[0042] (1) According to the mass ratio of 1:1.2:35, the activated clay with a particle size of 5 μm, a radial size of 7 μm, and amphiphilic graphene oxide, pentane and hexane with a thickness of 1.5 nm are weighed;

[0043] (2) Add the amphiphilic graphene oxide into an organic solvent, disperse by ultrasonic, the ultrasonic power is 2kW, and the ultrasonic time is 45 minutes to obtain a uniform dispersion, then add activated clay, stir at high speed, and the speed of stirring at high speed is 900rpm, The stirring time is 65 minutes, and the amphiphilic graphene oxide is uniformly wrapped with activated clay, and the viscosity is adjusted to obtain an activated clay / amphiphilic graphene oxide composite dispersion with a viscosity of 3.8 Pa·s;

[0044] (3) by scraping method, control described scraping coating coating speed to be 210nm / min, described activated clay / amphiphilic graphene oxide composite dispersion liquid is coated on the hyperbranched polyurethane film substrate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com