Manufacturing method of interlayer cross line connecting structure, and circuit board

A technology of connection structure and production method, which is applied in the direction of mechanically removing conductive materials, printed circuit, printed circuit manufacturing, etc., can solve the problems of blocked vias, high production cost, low production efficiency, etc. Small footprint and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

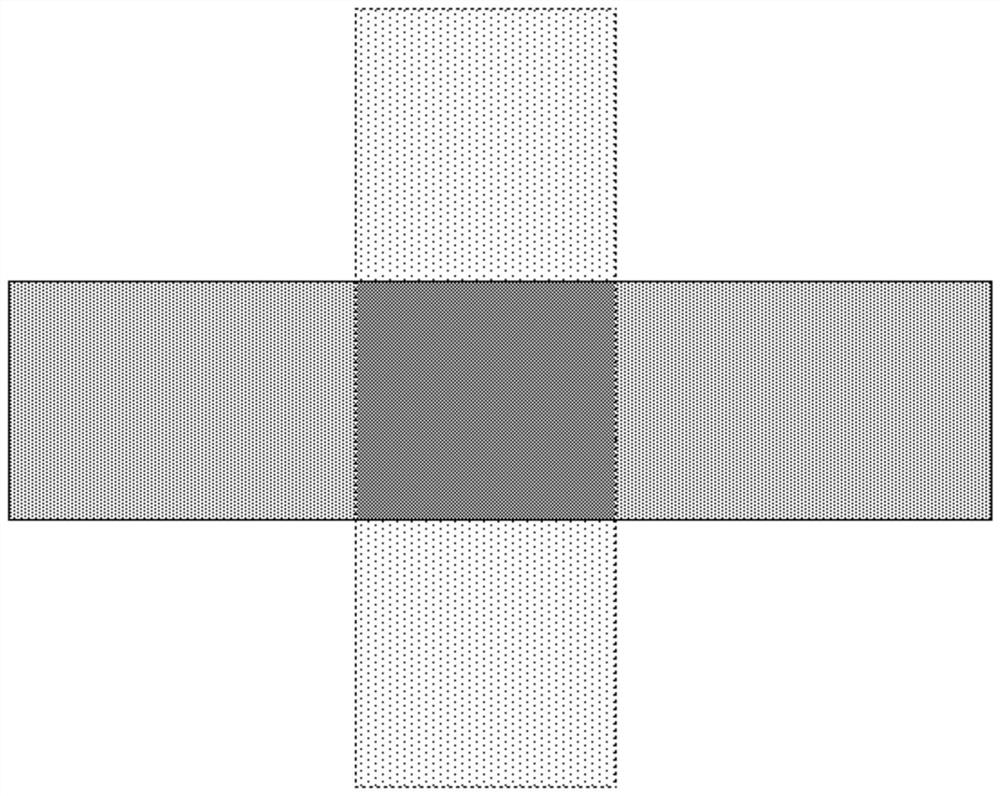

Image

Examples

Embodiment 1

[0053] A method for fabricating an interlayer cross-wire connection structure shown in this embodiment includes the following processing steps in sequence:

[0054] (1) Cutting: Prepare an insulating substrate with a size of 500*600 mm and a thickness of 25 μm, which is a polyimide film (ie, a PI film).

[0055] (2) Laser scribing: Use a 355 nm UV laser to ablate the first connecting line groove with a depth of 15 μm on the first surface of the insulating substrate, and the length of the first connecting line groove is 0.1 mm and the width is 20 μm ; In other specific embodiments, it is also possible to set the depth of the first connecting line groove to be ≥ 1 / 2 of the thickness of the insulating substrate and less than the thickness of the insulating substrate.

[0056] (3) Laser grooving: use 355 nm UV laser to ablate the first circuit groove with a depth of 10 μm on the first surface of the insulating substrate according to the circuit pattern required by the design, and ...

Embodiment 2

[0069] The manufacturing method of a kind of interlayer cross wire connection structure shown in this embodiment is basically the same as the manufacturing method described in Embodiment 1, the difference is that the following steps are also included after step (8):

[0070] (9) Grinding plate: After nickel sinking, the surface of the plate is smoothed by grinding the plate, so that the surface of the precision circuit is flush with the surface of the insulating substrate.

Embodiment 3

[0072] A method for fabricating an interlayer cross-wire connection structure shown in this embodiment includes the following processing steps in sequence:

[0073] (1) Cutting: Prepare a PI film with a size of 500*600mm and a thickness of 25 μm and an inner core board with the same length and width. The inner core board is a double-sided copper-clad core board, and the middle of the inner core board The dielectric layer thickness is 0.15mm.

[0074] (2) Making the inner layer circuit: the inner layer circuit is made on the two surfaces of the inner layer core board by adopting the negative process.

[0075] (3) Film: Paste PI film on both surfaces of the inner core board to form a production board.

[0076](4) Laser scribing: On the first surface of the production board, a UV laser of 355 nanometers is used to ablate the first connecting line groove with a depth of 0.1 mm, a width of 20 μm, and a depth of more than 0.075mm+25μm and less than 0.15mm+25μm.

[0077] (5) Laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com