A method for extracting and separating rare earth yttrium by using pyridine carboxylic acid ionic liquid

A pyridine carboxylic acid, ionic liquid technology, applied in the direction of improving process efficiency, can solve the problems of difficult to achieve high-efficiency separation and purification of yttrium, low separation coefficient, easy volatility, etc., achieves no saponification in operation, good separation performance, and improved selection. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

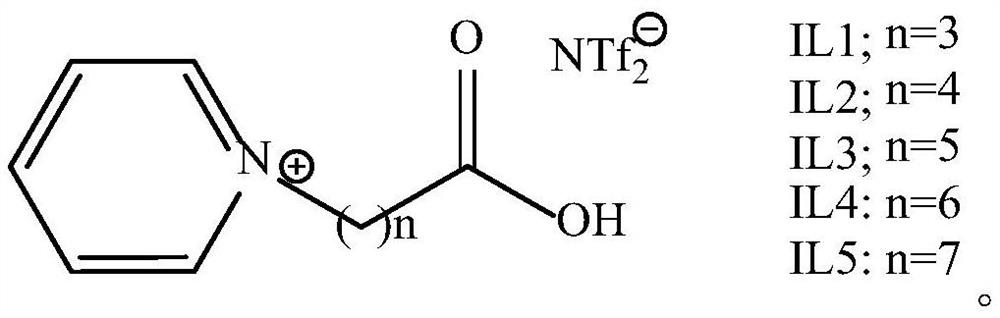

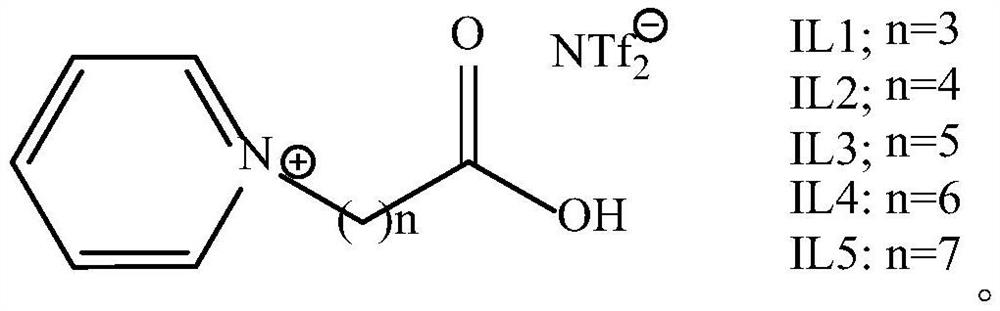

[0033] Ionic liquid [(CH 2 ) n Preparation of COOHpyr][Br], n=3,4,5,6,7

[0034] Dissolve 0.2mol of 4-bromobutyric acid, 5-bromopentanoic acid, 6-bromohexanoic acid, 7-bromoheptanoic acid, and 8-bromooctanoic acid in 50ml of ethanol, and then add them dropwise to a three-necked flask containing equimolar pyridine , stirred magnetically at 70°C for 48h, condensed and refluxed. After the reaction, a precipitate was produced, and the excess ethanol was removed by rotary evaporation. The product was washed more than 10 times with ethyl acetate, and dried under vacuum at 65 °C for 48 h to obtain 5 powdery solids [(CH 2 ) n COOHpyr][Br], n=3, 4, 5, 6, 7, the yields were 88.4%, 89.6.7%, 93.1%, 95.7%, 95.8%, respectively.

Embodiment 2

[0036] Ionic liquid [(CH 2 ) n COOHpyr][NTf 2 ], the preparation of n=3,4,5,6,7

[0037] LiNTf 2 Respectively with the [(CH 2 ) n COOHpyr] [Br], n = 3, 4, 5, 6, 7, ion exchange reaction was performed in deionized water, magnetically stirred at room temperature for 12 hours, left to stand and separated, and the lower layer was the reaction product. The product was washed several times with deionized water until no white precipitate was detected by saturated silver bromide solution, and then the P 2 o 5 As a desiccant, vacuum-dried at 65°C for 24 hours to obtain five viscous ionic liquids [(CH2 ) n COOHpyr][NTf 2 ], n=3, 4, 5, 6, 7, the yields were 89.3%, 92.7%, 93.8%, 95.7%, 96.5%, respectively.

Embodiment 3

[0039] Pyridine carboxylic acid ionic liquid [(CH 2 ) 3 COOHpyr][NTf 2 ] to the extraction and separation of yttrium

[0040] 1) The rare earth hydrochloric acid solution containing yttrium is used as the raw material liquid, the concentration of yttrium in the raw material liquid is 0.015mol / L, and the pH value is 2.51.

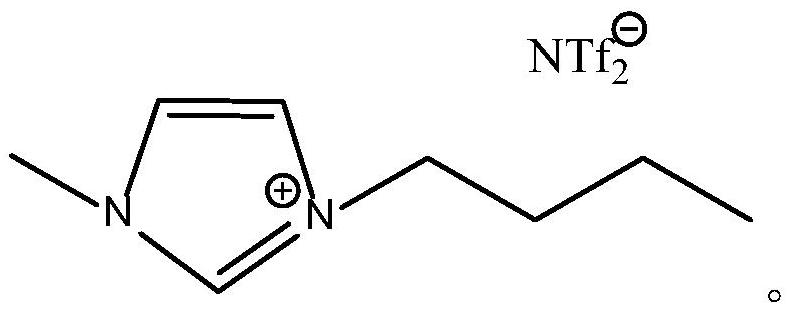

[0041] 2) configure the ionic liquid phase, select pyridine carboxylic acid ionic liquid [(CH 2 ) 3 COOHpyr][NTf 2 ] is the extractant, select [C 4 mim][NTf 2 ] As a diluent, the concentration of the extractant in the ionic liquid phase is 0.2mol / L.

[0042] 3) The raw material liquid and the ionic liquid phase were mixed and extracted in a constant temperature water bath oscillator, the extraction time was 5 min, the temperature was 25° C., and the rotation speed during the extraction and stripping process was 200 r / min. The concentration of rare earth elements in raffinate was measured by ICP method, and the results showed that the extraction rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com