Liquid metal heating directional solidification device and casting method

A technology of directional solidification and liquid metal, applied in the field of investment precision casting, can solve the problems of low efficiency, achieve the effect of improving heat transfer efficiency and temperature gradient, and eliminating freckle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

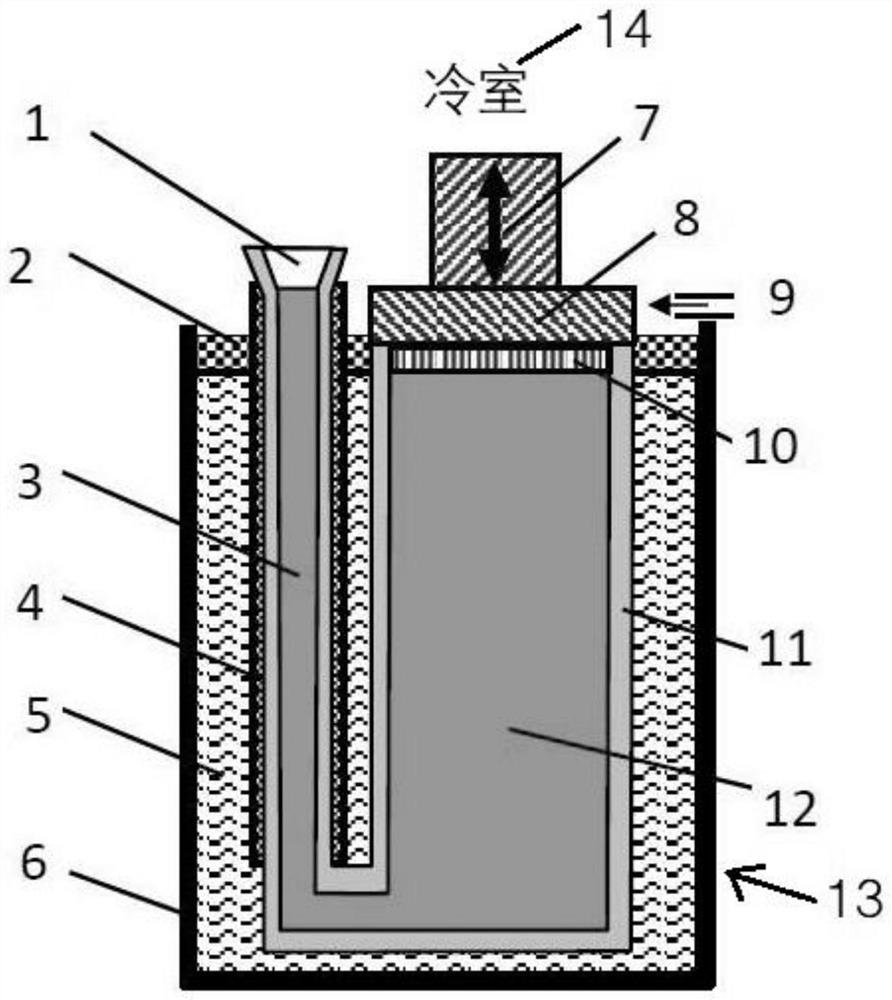

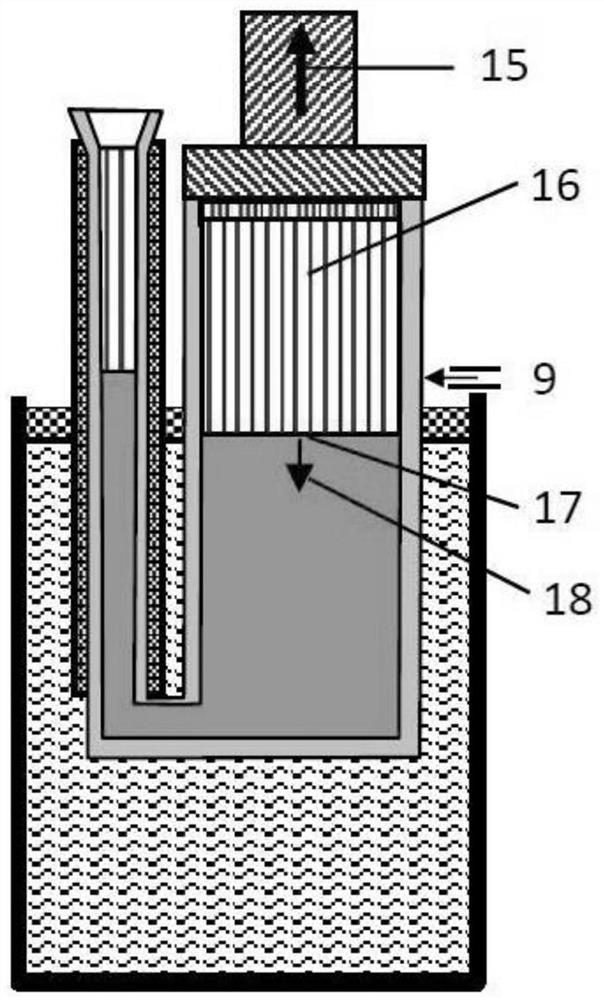

[0026] like figure 1 and figure 2 As shown, the present invention provides a liquid metal heating directional solidification device, comprising a cold chamber 14 and a hot chamber 13, a lifting device 7, a mold shell 11, the mold shell 11 top is an opening, and the opening is provided with The chilling plate 8 is covered, the cold chamber 14 is arranged above the hot chamber 13 , and the lifting device 7 is arranged above the chilling plate 8 . A thermal insulation layer 2 is provided between the hot chamber 13 and the cold chamber 14 , and the formwork 11 is disposed in the thermal chamber 13 through the thermal insulation layer 2 .

[0027] A plurality of nozzles 9 for spraying a cooling medium are arranged in the cold chamber 14, and the nozzles 9 are arranged around the mold shell 11, and the cooling medium is argon. While lifting the mold shell 11, spray argon gas to the mold shell 11 through the nozzle 9 for cooling, so that the heat dissipation efficiency is greatly ...

Embodiment 2

[0035] The present invention also provides a method of directional solidification casting based on the liquid metal heating directional solidification device described in Embodiment 1. Refer to figure 1 and figure 2 , including the steps:

[0036] S1: Fill the crucible 6 in the heat chamber 13 with Al alloy material, heat it through induction or resistance heater until it melts to form liquid metal 5, and replenish Al alloy material so that the upper surface of liquid metal 5 is close to the upper edge of crucible 6 , the distance is 10 to 50mm, forming a liquid metal molten pool, and the temperature is kept at 700°C to 1500°C; a heat insulating layer 2 is set on the liquid metal molten pool, the thickness of the heat insulating layer is 5 to 30mm, and the material of the heat insulating layer 2 can be hollow Ceramic balls, with a diameter of 1 to 5mm, or liquid mold powder.

[0037] S2: Lower the formwork 11 connected to the chilling plate 8 into the liquid metal molten po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com