Directional solidification device and casting method

A technology of directional solidification and lifting device, which is applied in the field of precision casting, can solve the problems of freckles in single crystal blade casting process, and achieve the effect of eliminating freckle defects and avoiding convection phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

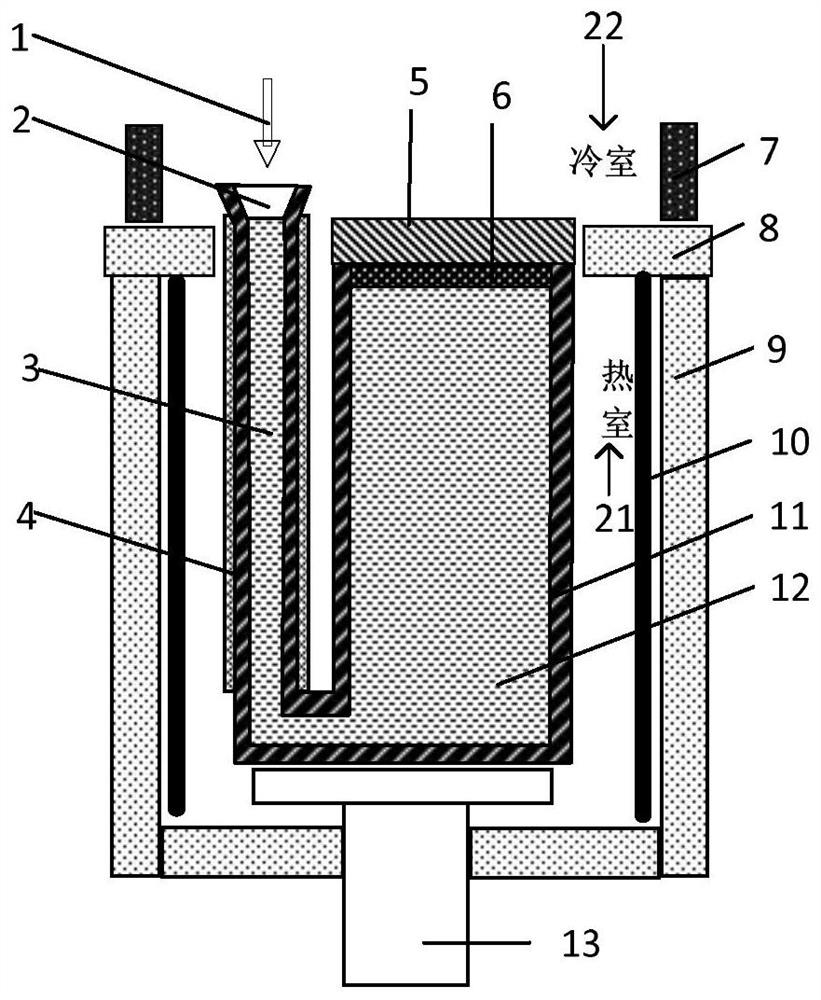

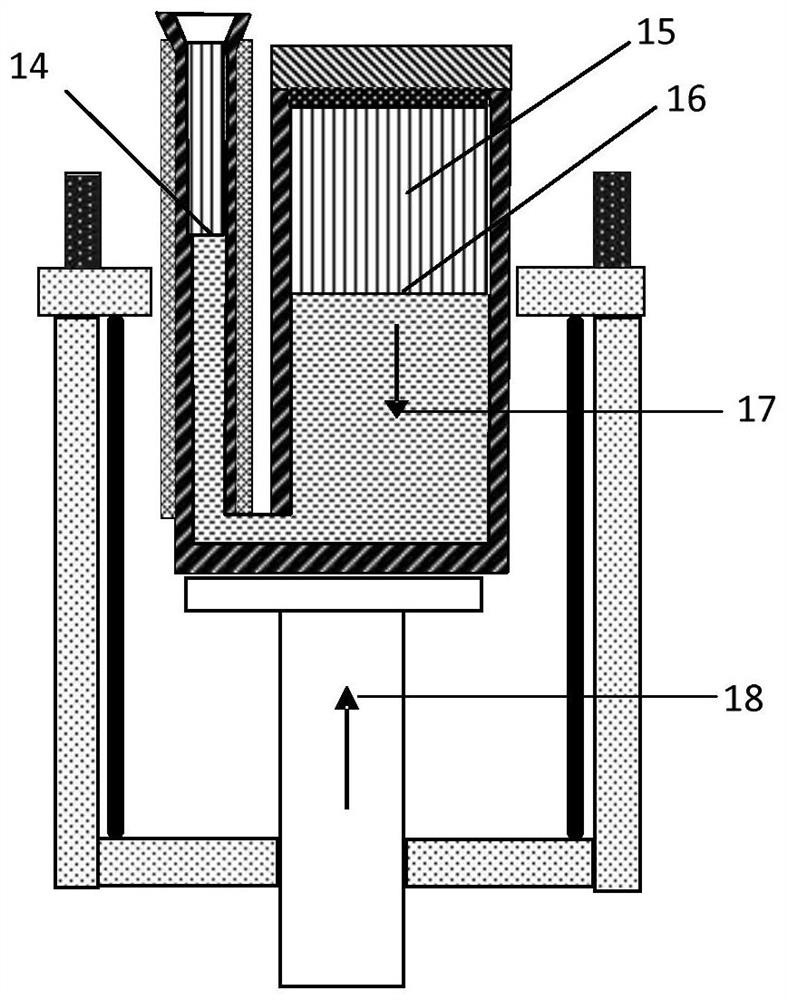

[0025] like figure 1 and figure 2 As shown, the present invention provides a kind of directional solidification device, and described device comprises: hot room 21 and cold room 22, and described cold room 22 is arranged on the top of described hot room 21, and described hot room 21 and cold room 22 A heat insulating board 8 is provided between them.

[0026] Wherein, a heater 10, a lifting device 13, and a mold shell 11 are arranged in the hot chamber 21, a cooling ring 7 is arranged in the cold chamber 22, and the heater 10 is arranged around the mold shell 11; The upper part of the mold case 11 is open, and a cooling plate 5 is arranged at the opening for sealing.

[0027] In this embodiment, the runner of the mold shell 11 is a sprue 3 , and the sprue 3 is arranged on one side of the mold shell 11 and communicates with the cavity 12 of the mold shell 11 at the bottom. The sprue wrapped by the insulation material forms a liquid pressure head with a certain height differ...

Embodiment 2

[0036] The present invention also provides a method for directional solidification casting based on the directional solidification device described in Embodiment 1, refer to figure 1 and figure 2 , which includes the steps:

[0037] S1, placing the formwork 11 in the heat chamber 21 for preheating;

[0038] S2, pour the alloy liquid through the gate 2 of the mold shell 11 along the direction of gravity 1, so that the alloy liquid enters the cavity 12 through the sprue 3, rises to the top opening and contacts the cooling plate 5 to form a cooling layer 6;

[0039] S3, after the pouring is completed, the mold shell 11 after pouring is passed through the heat insulating plate 8 by the hot chamber 21 to the cold chamber 22 at a predetermined speed through the lifting device 13 along the upward direction 18, and the rising speed is controlled at 1 to 10 mm / min. During the rising process of the mold shell, the molten metal in the mold shell gradually solidifies downward from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com