Recycled water treatment adsorption material and preparation method thereof

An adsorption material and recycling technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of decreased adsorption capacity, poor industrial practicability, and reduced adsorption performance. Excellent recyclability and strong industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

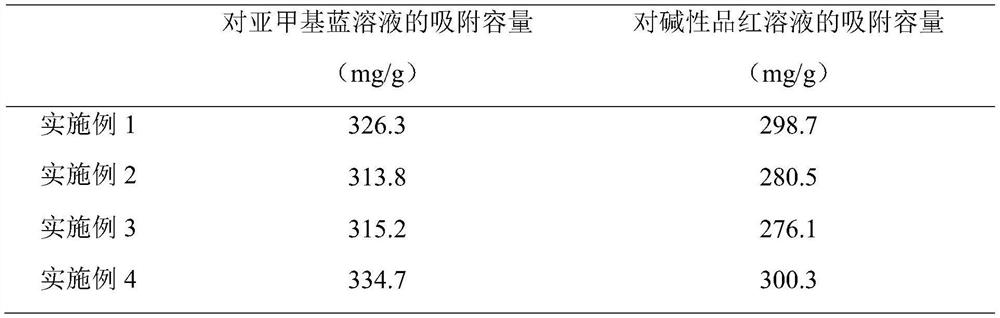

Embodiment 1

[0039] A kind of circulating regeneration water treatment adsorption material of embodiment 1, comprises the following components by weight: 0.2 parts of activated carbon, 1 part of methyl methacrylate monomer, 0.05 parts of benzoyl peroxide, 0.4 parts of rosin-based dienes, toluene 2 parts, 10 parts of acetophenone, 0.1 part of ferric chloride hexahydrate, 0.1 part of sodium acetate, 0.05 part of poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt, 20 parts of ethylenediamine 10 parts of methanol and 10 parts of solvent, the solvent is a mixture of polyvinyl alcohol and deionized water, the mass ratio of polyvinyl alcohol to deionized water is 1:0.8-1.5.

[0040] A kind of preparation method of recycled water treatment adsorption material of embodiment 1, comprises the following steps:

[0041] S1. Preparation of activated carbon composite polymethyl methacrylate microspheres: add methyl methacrylate monomer, benzoyl peroxide and rosin-based diene, stir evenly...

Embodiment 2

[0046] A kind of recycled water treatment adsorption material of embodiment 2, comprises the following components by weight: 2 parts of activated carbon, 10 parts of methyl methacrylate monomer, 0.5 part of cyclohexyl peroxydicarbonate, 2 parts of divinylbenzene , 10 parts of xylene, 50 parts of acetophenone, 2 parts of ferric chloride hexahydrate, 1 part of sodium acetate, 2 parts of polystyrene sulfonic acid, 50 parts of ethylenediamine, 50 parts of ethanol and 40 parts of solvent. The solvent is a mixture of polyvinyl alcohol and deionized water, and the mass ratio of polyvinyl alcohol to deionized water is 1:1.5.

[0047] A kind of preparation method of recycled water treatment adsorption material of embodiment 2, comprises the following steps:

[0048] S1. Preparation of activated carbon composite polymethyl methacrylate microspheres: add methyl methacrylate monomer, cyclohexyl peroxydicarbonate and divinylbenzene, stir evenly, add activated carbon, stir, add xylene, ultr...

Embodiment 3

[0053] A recycled water treatment adsorption material in Example 3, including the following components by weight: 0.5 parts of activated carbon, 2 parts of methyl methacrylate monomer, 0.15 parts of azobisisobutyronitrile, triene instead of divinylbenzene 0.2 parts, 3 parts of kerosene, 20 parts of acetophenone, 0.3 parts of ferric chloride hexahydrate, 0.3 parts of sodium acetate, 0.3 parts of polyacrylic acid, 25 parts of ethylenediamine, 20 parts of ethylene glycol and 20 parts of solvent, the The solvent is a mixture of polyvinyl alcohol and deionized water, and the mass ratio of polyvinyl alcohol to deionized water is 1:1.

[0054] The preparation method of the recycled water treatment adsorption material of embodiment 3 comprises the following steps:

[0055] S1. Preparation of activated carbon composite polymethyl methacrylate microspheres: add methyl methacrylate monomer, azobisisobutyronitrile and triene instead of divinylbenzene, stir evenly, add activated carbon, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com