Formed mushroom dreg matrix block

A technology of matrix block and fungus residue, which is applied in planting matrix, culture medium, gardening and other directions, can solve the problems of inconvenient mechanical large-scale operation, matrix is not easy to form, matrix block is easy to drop slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

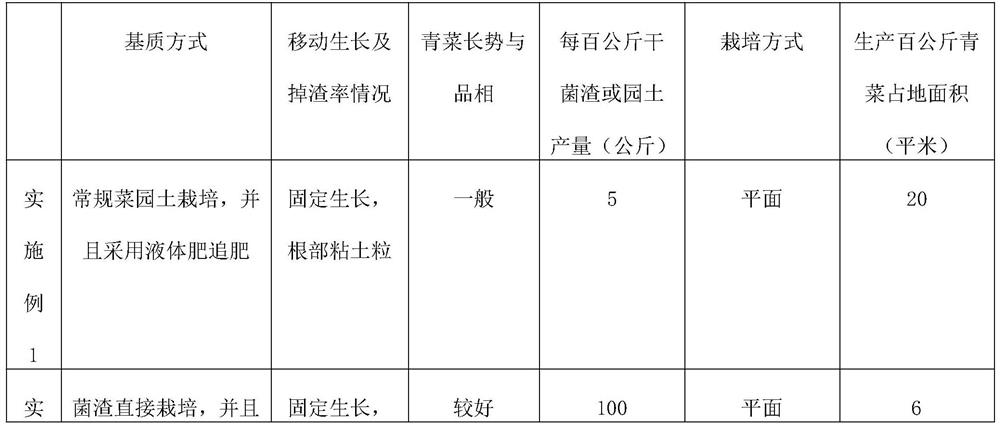

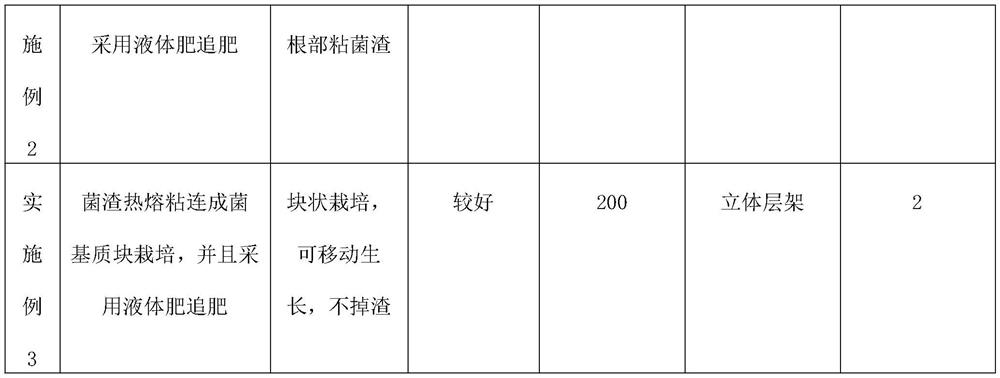

Embodiment 1

[0047] 1) Cultivation with conventional vegetable garden soil: select 5 portions of relatively qualified vegetable garden soil, each portion contains 100 kg (dry) vegetable garden soil, and the expansion area is about 1 square meter, and each portion of vegetable garden soil is paved into a plane to simulate conventional vegetable garden planting, and then Sow vegetable seeds on the vegetable garden soil;

[0048] 2) After the above 1) sowing, choose a suitable sowing time and use conventional planting methods to apply liquid fertilizer to the vegetable seedlings, and then place the vegetable seedlings in an environment with suitable temperature and humidity to grow until the finished product is picked.

[0049] After the green vegetable finished product of above 2) grows mature, because the soil is paved and the conventional planting soil cannot be moved, the organic matter content is small, and the root of the green vegetable sticks to the soil particles to grow, the green ve...

Embodiment 2

[0051] 1) Cultivation with crushed fungus slag: add nutrients during the cultivation of edible fungi and collect the mycelium and sawdust produced after the cultivation of edible fungi to form a fungal slag matrix. The bacterium slag matrix after pulverizing puts into the sieving machine to screen out the bacterium slag grain, selects 5 parts of the bacterium slag grain, each part is equipped with 100 kilograms of (dry) bulk bacterium slag grains, and every share of bacterium slag grains is paved into a flat 6 square meters, using Plant by conventional planting methods, and then sow green vegetable seeds on the slag grains;

[0052] 2) After the above 1) sowing, select a suitable sowing time and use conventional planting methods to topdress the vegetable seedlings with liquid fertilizer, and then place the vegetable seedlings in an environment with suitable temperature and humidity to grow until the finished product is picked;

[0053] After the finished product of the above-m...

Embodiment 3

[0055] Cultivation with molded slag substrate blocks:

[0056] 1) Formation of the fungus residue matrix block: the nitrogen content components and nutrients added in the process of cultivating edible fungi and the mycelium and sawdust produced after the cultivation of edible fungi are collected to form the fungus residue matrix, and the fungus residue matrix pulverizer is repeatedly After the crushing treatment, put the crushed bacteria residue matrix into the screening machine to screen out the bacteria residue particles; the formed bacteria residue particles are stirred and bonded by high-molecular organic plastic particles at a temperature of 150-300°C to form a bacteria residue bond The fungus residue adhesive is passed through the required container to form a molded residue adhesive, and then the mold residue adhesive with a number of holes is fully dried or air-dried to make the bacterial residue The binder forms a molded slag matrix block;

[0057] 2) Add liquid ferti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com