Preparation method of 3DOM bulk hydrogenation catalyst

A hydrogenation catalyst, 3DOM technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Give full play to the problems of deep hydrogenation activity and poor dispersion of catalyst metals to achieve the effects of increased effective catalytic area, dense active components, and reduced mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of 3DOM bulk type hydrogenation catalyst, comprising the following steps:

[0047] Measure 30ml of methyl methacrylate (MMA) solution, extract 3 times with 30ml of 0.1mol / L NaOH solution, and then extract with 30ml of deionized water until neutral to remove the polymerization inhibitor (hydroquinone).

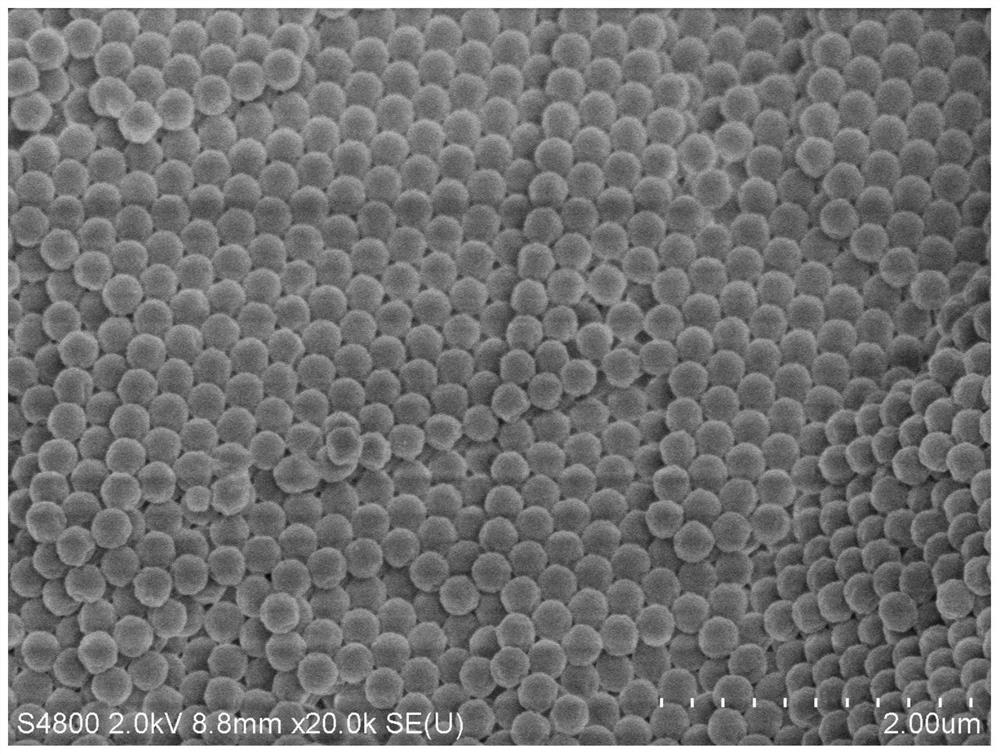

[0048]Add 650ml of deionized water into the four-neck flask, pass through nitrogen protection, heat up to 70°C, add 0.0036g of sodium lauryl sulfate, start stirring, keep the speed at 350rpm, add 30ml of MMA, stir for 15min, remove the polymerization inhibitor, Add 0.2g of potassium persulfate, stir for 1 hour, turn off the stirring, take out the emulsion, put it into a centrifuge tube, centrifuge for 5 hours, the centrifugal speed is 2000rpm, and dry in a water bath at 40°C for 5 hours to prepare a PMMA microsphere template with obvious Bragg light effect agent.

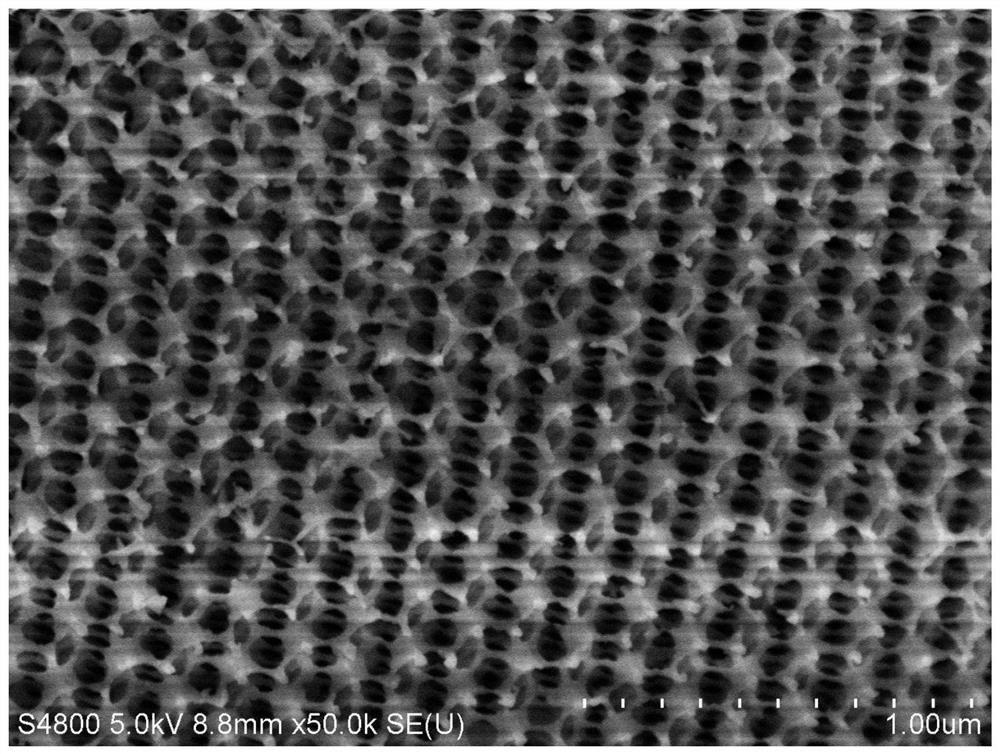

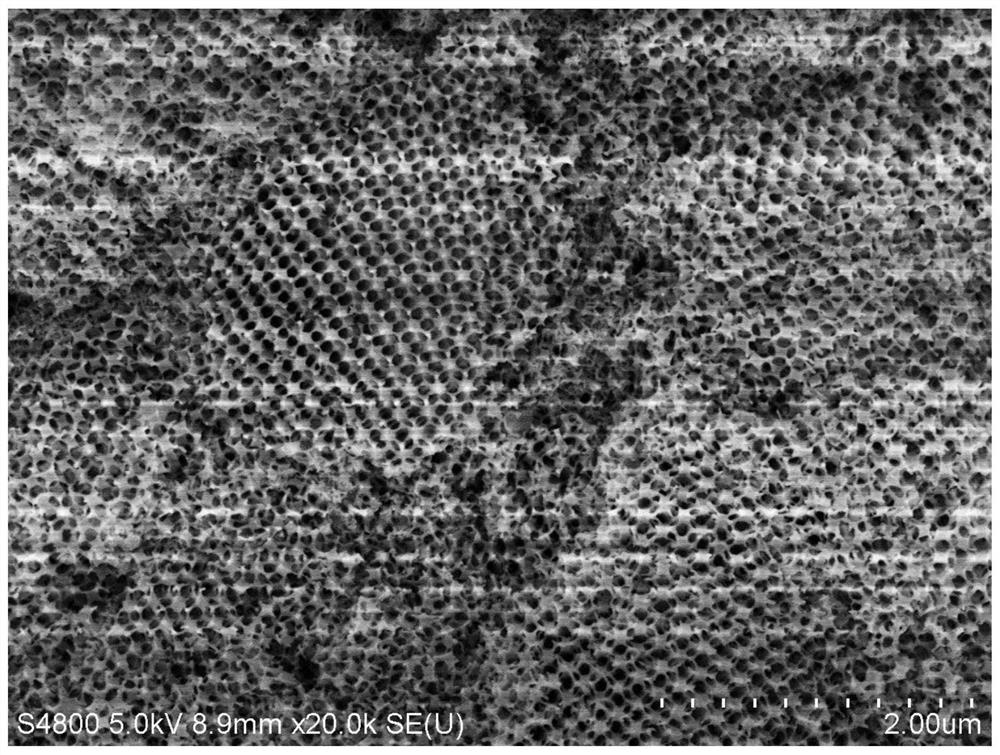

[0049] Weigh 0.5885g ammonium molybdate, 1.9387g nickel nitrate, 0.5ml nitric acid, 0...

Embodiment 2

[0051] A preparation method of 3DOM bulk type hydrogenation catalyst, comprising the following steps:

[0052] Measure 30ml of MMA solution, extract 3 times with 30ml of 0.1mol / L NaOH solution, and then extract with 30ml of deionized water until neutral to remove polymerization inhibitor (hydroquinone). Add 650ml of deionized water into the four-neck flask, pass through nitrogen protection, heat up to 70°C, add 0.0036g of sodium lauryl sulfate, start stirring, keep the speed at 350rpm, add 30ml of MMA, stir for 15min, remove the polymerization inhibitor, Add 0.2g of potassium persulfate, stir for 1 hour, turn off the stirring, take out the emulsion, put it into a centrifuge tube, centrifuge for 5 hours, the centrifugal speed is 2000rpm, and dry in a water bath at 40°C for 5 hours to prepare a PMMA microsphere template with obvious Bragg light effect agent.

[0053] Weigh 0.8987g ammonium metatungstate, 1.9387g nickel nitrate, 0.5ml nitric acid, dissolve in methanol solution (...

Embodiment 3

[0055] A preparation method of 3DOM bulk type hydrogenation catalyst, comprising the following steps:

[0056] Measure 30ml of MMA solution, extract 3 times with 30ml of 0.1mol / L NaOH solution, and then extract with 30ml of deionized water until neutral to remove polymerization inhibitor (hydroquinone). Add 650ml of deionized water into the four-neck flask, pass through nitrogen protection, heat up to 70°C, add 0.0036g of sodium lauryl sulfate, start stirring, keep the speed at 350rpm, add 30ml of MMA, stir for 15min, remove the polymerization inhibitor, Add 0.2g of potassium persulfate, stir for 1 hour, turn off the stirring, take out the emulsion, put it into a centrifuge tube, centrifuge for 5 hours, the centrifugal speed is 2000rpm, and dry in a water bath at 40°C for 5 hours to prepare a PMMA microsphere template with obvious Bragg light effect agent.

[0057] Weigh 0.2928g ammonium molybdate, 0.4493g ammonium metatungstate, 1.9387g nickel nitrate, 0.5ml nitric acid, 0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com