Lithium ion ternary nanosheet as well as preparation method and application thereof

A lithium ion, nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that ammonium bicarbonate material is harmful to human body, cannot be directly discharged into sewers, and is harmful to the environment. problem, to achieve the effect of improving electrochemical performance, good market prospect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

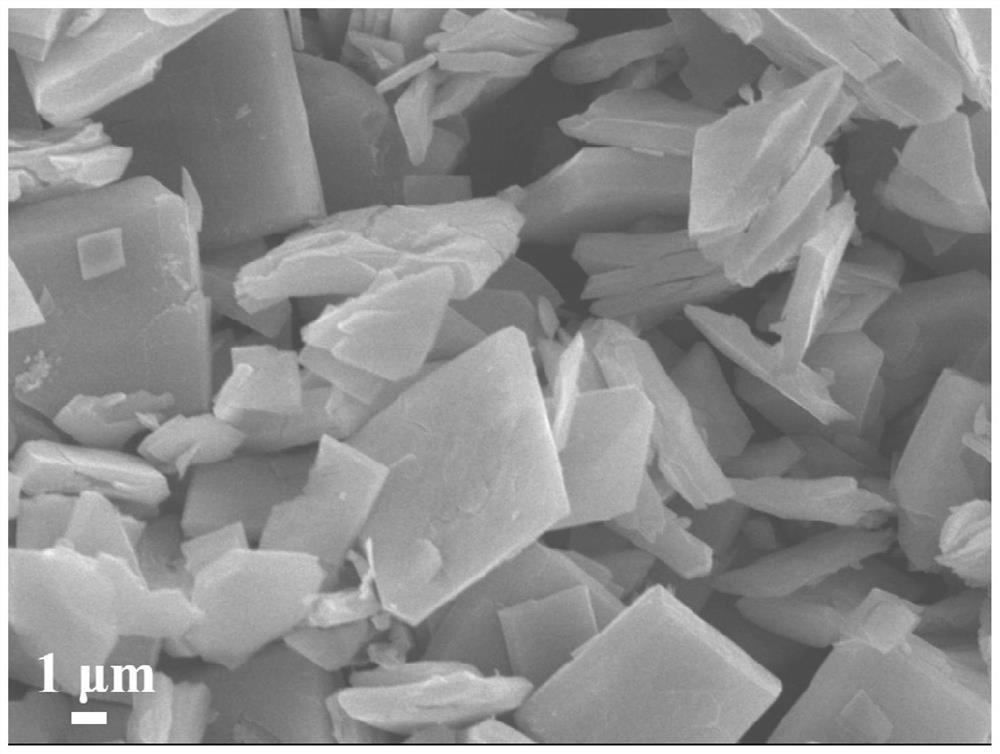

[0030] First, dissolve 8mmol potassium nickel cyanide in 400ml deionized water, stir magnetically until solution A is completely dissolved, then dissolve 4mmol cobalt acetate tetrahydrate, 4mmol iron acetate tetrahydrate, and 3mmol sodium citrate in 400ml deionized water, and stir magnetically Until solution B is completely dissolved, then slowly add solution A to solution B, stir for 30 minutes, then let the sample stand at room temperature for 24 hours, filter with suction, collect the sample and wash it several times with deionized water and ethanol, and finally Dry in a vacuum oven at 60° C. for 5 hours to obtain dry powder. Heat the powder in a tube furnace filled with nitrogen at 1°C / min, keep it warm for 1 hour when the temperature rises to 450°C, and then put the powder in a muffle furnace to raise the temperature at 1°C / min, and hold it for 0.5 Calcination was carried out for 2 hours to obtain the final sample.

[0031] figure 1 For the X-ray diffraction pattern of ...

Embodiment 2

[0034] First, dissolve 8mmol potassium nickel cyanide in 400ml deionized water, stir magnetically until solution A is completely dissolved, then dissolve 4mmol cobalt chloride, 4mmol ferric chloride, and 3mmol sodium citrate into 400ml deionized water, and stir magnetically until completely Dissolve solution B, then slowly add solution A to solution B, stir for 30 minutes, then let the sample stand at room temperature for 24 hours, filter with suction, collect the sample and wash it several times with deionized water and ethanol, and finally vacuum Dry in a drying oven at 60° C. for 5 hours to obtain a dry powder. Heat the powder in a tube furnace filled with nitrogen at 2°C / min, heat it up to 450°C for 1 hour for calcination, then place the powder in a muffle furnace to heat up at 3°C / min, heat it up to 300°C for 0.5 Calcination was carried out for 2 hours to obtain the final sample.

Embodiment 3

[0036] First dissolve 8mmol nickel potassium cyanide in 400ml deionized water, stir magnetically until solution A is completely dissolved, then dissolve 4mmol cobalt sulfate, 4mmol iron sulfate, and 3mmol sodium citrate into 400ml deionized water, stir magnetically until the solution is completely dissolved B, then slowly add solution A to solution B, stir for 30 minutes, then let the sample stand at room temperature for 48 hours, filter with suction, collect the sample and wash it several times with deionized water and ethanol, and finally put it in a vacuum oven Dry at 60°C for 5 hours to obtain dry powder. The powder is heated in a tube furnace filled with nitrogen at 2°C / min, and when the temperature is raised to 400°C, it is kept for 1 hour for calcination, and then the powder is placed in a muffle furnace to be heated at 2°C / min. Calcination was carried out for 2 hours to obtain the final sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com