Manufacturing method of super-long plate based on explosive welding and obtained super-long plate

A technology of explosive welding and manufacturing method, which is applied in the field of material processing and can solve the problems of difficult to ensure accurate quality control, high rolling pressure, and difficult to process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Copper alloy, cold deformation 60%, recrystallization temperature 850°C

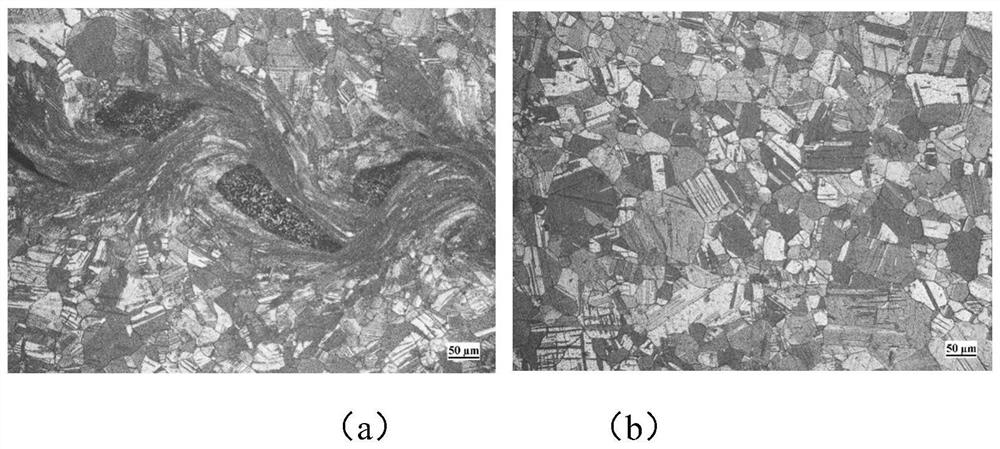

[0036] Copper alloy is used as the base metal alloy for manufacturing composite plates. The thickness of the flying plate and the base plate are 5mm and 15mm respectively. The copper alloy is processed to the corresponding thickness according to the plate size specification, and the surface of the alloy is cleaned. See figure 1 (b), figure 1 (b) is the microstructure of the alloy matrix. The alloy matrix structure is mainly α solid solution, the grain size is from tens to hundreds of microns, the compactness is good, and there are no defects such as pores and impurities. It can be used as the base metal alloy for explosive welding for the next step process.

[0037] Based on the explosive welding theory and empirical formula, and combined with the relevant constants of copper alloy materials, the explosive welding window of copper alloy is calculated, and the explosive welding parameters are dete...

Embodiment 2

[0042] Copper alloy, cold deformation 70%, recrystallization temperature 900°C

[0043] Copper alloy is used as the base metal alloy for the manufacture of composite plates, the thickness of the fly plate and the base plate are 5mm and 15mm respectively, the copper alloy is processed to the corresponding thickness according to the plate size specification, and the surface of the alloy is cleaned;

[0044] Based on the explosive welding theory and empirical formula, and combined with the relevant constants of copper alloy materials, the explosive welding window of copper alloy is calculated, and the explosive welding parameters are determined. 2300m / s, conduct explosive welding experiments, and manufacture pre-finished copper alloy composite plates with a certain length.

[0045] The pre-finished copper alloy composite plate is subjected to cold deformation treatment, and the total downforce of cold rolling is 70%, to obtain a composite plate with a total thickness of 6 mm. Th...

Embodiment 3

[0048] Copper alloy, cold deformation 60%, recrystallization temperature 950°C

[0049] The copper alloy is used as the base material alloy for the manufacture of the composite plate. The thickness of the fly plate and the base plate are 5mm and 15mm respectively. The copper alloy is processed to the corresponding thickness according to the plate size specification, and the surface of the alloy is cleaned. Based on the explosive welding theory and empirical formula, combined with the relevant constants of copper alloy materials, the explosive welding window of copper alloy is calculated, and the explosive welding parameters are used. 2300m / s, conduct explosive welding experiments, and manufacture pre-finished copper alloy composite plates with a certain length.

[0050] The pre-finished copper alloy composite plate is subjected to cold deformation treatment, and the total downforce of cold rolling is 60%, so as to obtain a composite plate with a total thickness of 8mm. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Recrystallization temperature | aaaaa | aaaaa |

| Recrystallization temperature | aaaaa | aaaaa |

| Recrystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com