Ultrathin metal lithium electrode, preparation method thereof, and application of ultrathin metal lithium electrode as negative electrode of secondary lithium battery

An ultra-thin metal and lithium electrode technology, applied in lithium batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of waste of metal lithium capacity, mismatch of the capacity of metal lithium negative electrode and positive electrode material, safety hazards, etc., to achieve excellent Effects of Safety, Excellent Coulombic Efficiency and Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a preparation method of the ultra-thin metal lithium electrode of the present invention, such as figure 1 shown, including steps:

[0043] Heating step S101: heating and melting metal lithium or lithium alloy in an inert gas environment to obtain liquid metal lithium;

[0044] Mixing step S102: adding the added ingredients and the skeleton ingredients into the liquid metal lithium in sequence, and mixing and dispersing to obtain a mixed lithium slurry;

[0045] Covering step S103: coating the mixed lithium slurry on the current collector layer to form a thin film layer, and after the thin film layer is cooled and solidified, an ultra-thin metal lithium electrode is obtained.

Embodiment 2

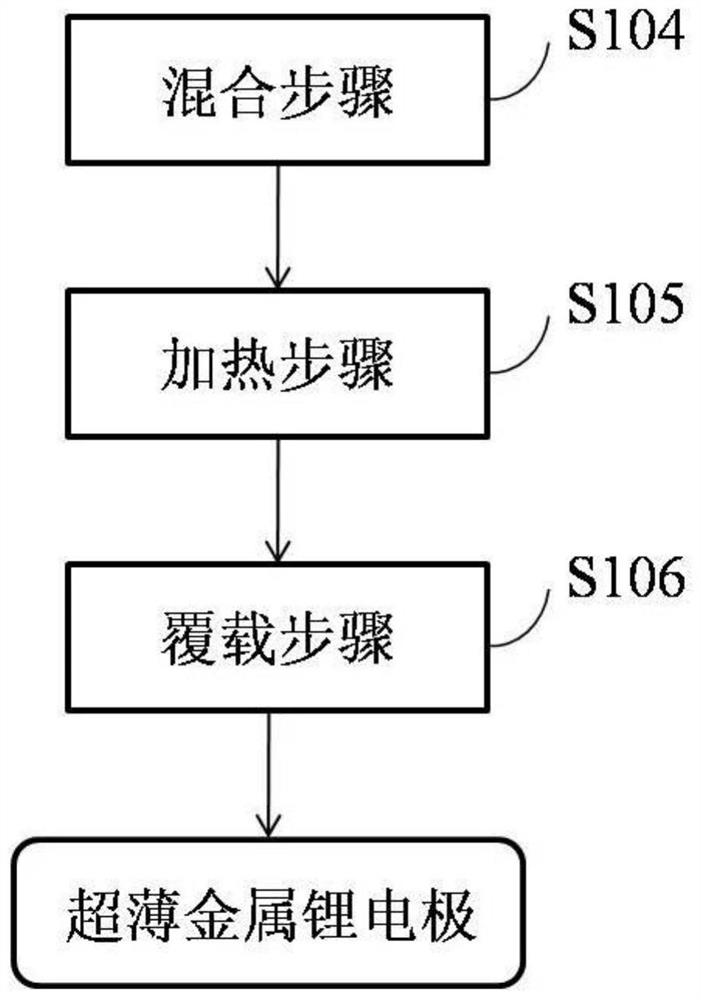

[0047] This embodiment provides another embodiment of the preparation method of the ultra-thin metal lithium electrode of the present invention, such as figure 2 shown, including steps:

[0048] Mixing step S104: in an inert gas environment, physically mix metal lithium or lithium alloy with additive components and skeleton components to obtain a mixture;

[0049] Heating step S105: heating the mixture until the metal lithium is melted to obtain a mixed lithium slurry;

[0050] Covering step S106: coating the mixed lithium slurry on the current collector layer to form a thin film layer, and after the thin film layer is cooled and solidified, an ultra-thin metal lithium electrode is obtained.

[0051] In Examples 1 and 2, the lithium alloy contains alloying elements that reduce the surface tension of liquid metal lithium, and the alloying elements include: Mg, Al, In, Zn, Ag, Ca, Sr, Ba, Sc, Y, Rh, One or more of Ir, Pd, Pt, Au, Cd, Hg, Ga, Tl, Ge, Pb, As, Sb, Bi, B, S, Se o...

Embodiment 3

[0057] This embodiment provides a specific implementation method in Example 1, using the transition metal carbide titanium carbide (Ti) containing the alloying element Mg and the added component -F functional group 3 C2 F), and the skeleton component one-dimensional nanomaterial carbon nanotube as an example, specifically illustrate the preparation method of the ultra-thin metal lithium electrode of the present invention, comprising steps:

[0058] Heating step: In an atmosphere of argon (purity greater than 99.999%), add 400 mg of metallic lithium block into a stainless steel pot and heat to 200° C. to melt the metallic lithium block into a liquid state.

[0059] Mixing steps: keep the heating temperature, first add 40mg metal magnesium flakes to the liquid metal lithium, then add 50mg Ti 3 C 2 F, stirring and mixing, the metal magnesium flakes are melted to form a liquid lithium-magnesium alloy, and then 50 mg of carbon nanotubes are added thereto, and the stirring is conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com