Nanometer spraying process for iron guardrail

A kind of guardrail and nano technology, which is applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem that the painting process cannot meet the long-term use, and achieve the effect of good barrier properties and increased adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

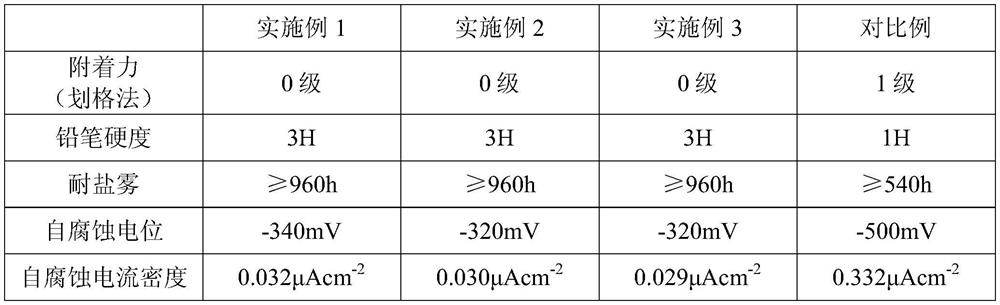

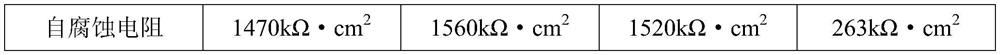

Examples

Embodiment 1

[0028] A nano-spraying process for wrought iron guardrails, comprising the following steps:

[0029] (1) Treatment of the base surface of the guardrail: first remove the floating soil, oil stains, welding slag, burrs and other foreign matter on the surface of the guardrail, and then use the physical derusting method for surface derusting operation;

[0030] (2) Primer spraying: Spray one layer of zinc-rich primer on the treated metal structure surface by spraying, the zinc-rich primer includes the following components in parts by weight: 15 parts of bisphenol A epoxy resin, 12 parts of zinc phosphate, 21 parts of water, 2 parts of talcum powder, 7 parts of polyamide resin curing agent. Dry for 10 hours after spraying, and the paint film thickness is 30 μm.

[0031] (3) intermediate paint spraying: on the guardrail that step (2) is brushed with primer, brush one deck polyurethane coating; Described polyurethane coating comprises the following components of weight part: 1,6-hex...

Embodiment 2

[0034] A nano-spraying process for wrought iron guardrails, comprising the following steps:

[0035] (1) Guardrail base surface treatment: first remove floating soil, oil stains, welding slag, burrs and other foreign matter on the surface of the guardrail, and then use chemical derusting method for surface derusting operation, use 50% phosphoric acid solution to rust the base material surface pickling;

[0036] (2) Primer spraying: Spray one layer of zinc-rich primer on the treated metal structure surface by spraying, the zinc-rich primer includes the following components in parts by weight: 15 parts of bisphenol A epoxy resin, 12 parts of zinc phosphate, 21 parts of water, 2 parts of talcum powder, 7 parts of polyamide resin curing agent. Dry for 12 hours after spraying, and the paint film thickness is 40 μm.

[0037] (3) intermediate paint spraying: on the guardrail that step (2) is brushed with primer, brush one deck polyurethane coating; Described polyurethane coating co...

Embodiment 3

[0040] A nano-spraying process for wrought iron guardrails, comprising the following steps:

[0041] (1) Treatment of the base surface of the guardrail: first remove the floating soil, oil stains, welding slag, burrs and other foreign matter on the surface of the guardrail, and then use the physical derusting method for surface derusting operation;

[0042] (2) Primer spraying: Spray one layer of zinc-rich primer on the treated metal structure surface by spraying, the zinc-rich primer includes the following components in parts by weight: 15 parts of bisphenol A epoxy resin, 12 parts of zinc phosphate, 21 parts of water, 2 parts of talcum powder, 7 parts of polyamide resin curing agent. Dry for 11 hours after spraying, and the paint film thickness is 40 μm.

[0043] (3) intermediate paint spraying: on the guardrail that step (2) is brushed with primer, brush one deck polyurethane coating; Described polyurethane coating comprises the following components of weight part: 1,6-hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com