Low-cost high-heat-dissipation intelligent function module

A technology with intelligent functions and high heat dissipation, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as poor heat dissipation performance, high cost, and false soldering of pins, and achieve stable welding and good heat dissipation , the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

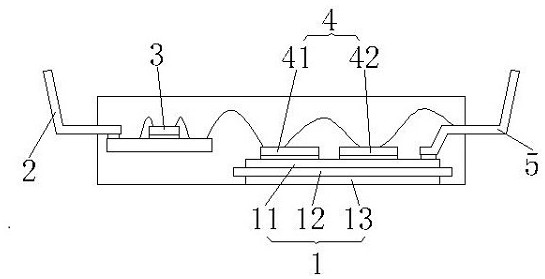

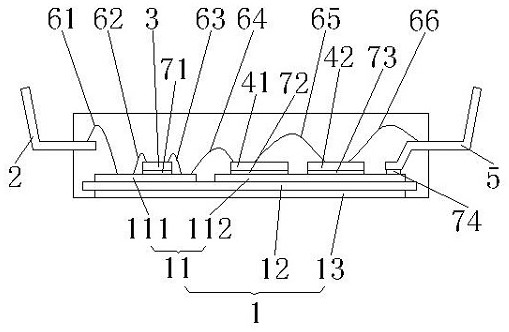

[0035] Such as Figure 1-2 As shown in , an embodiment of the present invention provides a low-cost high-heat dissipation intelligent functional module, including:

[0036] DBC substrate 1, the DBC substrate 1 is sequentially connected with a copper wiring layer 11, a ceramic layer 12, and a copper heat dissipation layer 13 from top to bottom. A copper wiring layer 111, a second copper wiring layer 112 disposed above the other end of the ceramic layer 12;

[0037] The first side pin 2, one end of the first side pin 2 is electrically connected to the first copper wiring layer 111 with a first bonding wire 61;

[0038] An IC chip 3, the IC chip 3 is welded on the first copper wiring layer 111, and a first solder layer 71 is provided between the IC chip 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com