Fireproof flame-retardant plastic optical cable and preparation method thereof

A fire-retardant and plastic optical fiber technology, applied in the field of optical cable materials, can solve problems such as narrow temperature range, poor heat resistance, and durability to be further improved, and achieve high preparation efficiency and finished product pass rate, reduce water absorption, Remarkable fire and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

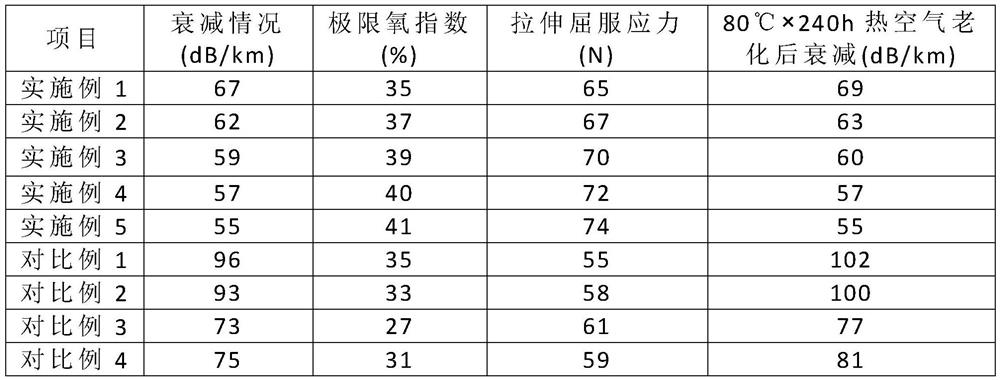

Examples

Embodiment 1

[0034] A fire-resistant and flame-retardant plastic optical cable, characterized in that it includes a plastic optical fiber and a sheath wrapped on the outside of the plastic optical fiber; the plastic optical fiber includes a plastic optical fiber core wire and a covering layer formed on the plastic optical fiber core wire; the plastic optical fiber The core wire is made from the following components in parts by weight: 100 parts of allyl methyl carbonate / GAMMA-butyrolactone-3-yl methacrylate / 2-methyl-4-pentanoic acid copolymer , Nano-hybrid hyperbranched polymer HB-SiO 2 4 parts, 1 part of boric acid; the covering layer is formed by curing the following raw materials by ultraviolet light: 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2 -5 parts of methacrylate, 15 parts of 2,2,3,3-tetrafluoropropyl methacrylate, 8 parts of vinyl hyperbranched polysiloxane, 1 part of glass fiber, 0.5 parts of coupling agent, optical 0.4 parts of initiator.

[0035] The sheath is a flam...

Embodiment 2

[0044] A fire-resistant and flame-retardant plastic optical cable, characterized in that it includes a plastic optical fiber and a sheath wrapped on the outside of the plastic optical fiber; the plastic optical fiber includes a plastic optical fiber core wire and a covering layer formed on the plastic optical fiber core wire; the plastic optical fiber The core wire is made from the following components in parts by weight: 100 parts of allyl methyl carbonate / GAMMA-butyrolactone-3-yl methacrylate / 2-methyl-4-pentanoic acid copolymer , Nano-hybrid hyperbranched polymer HB-SiO 2 5 parts, 1.2 parts of boric acid; the covering layer is formed by curing the following raw materials by ultraviolet light: 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2 - 6 parts of methacrylate, 17 parts of 2,2,3,3-tetrafluoropropyl methacrylate, 9 parts of vinyl hyperbranched polysiloxane, 1.5 parts of glass fiber, 0.6 parts of coupling agent, optical 0.5 parts of initiator.

[0045] The sheath is...

Embodiment 3

[0054] A fire-resistant and flame-retardant plastic optical cable, characterized in that it includes a plastic optical fiber and a sheath wrapped on the outside of the plastic optical fiber; the plastic optical fiber includes a plastic optical fiber core wire and a covering layer formed on the plastic optical fiber core wire; the plastic optical fiber The core wire is made from the following components in parts by weight: 100 parts of allyl methyl carbonate / GAMMA-butyrolactone-3-yl methacrylate / 2-methyl-4-pentanoic acid copolymer , Nano-hybrid hyperbranched polymer HB-SiO 2 6.5 parts, 1.5 parts of boric acid; the covering layer is formed by curing the following raw materials by ultraviolet light: 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2 - 6.5 parts of methacrylate, 20 parts of 2,2,3,3-tetrafluoropropyl methacrylate, 10 parts of vinyl hyperbranched polysiloxane, 2 parts of glass fiber, 1 part of coupling agent, optical 0.6 parts of initiator.

[0055] The sheath is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com