Wire rod for 5000MPa-grade diamond wire and production method thereof

一种生产方法、金刚线的技术,应用在热处理浴、热处理设备、制造工具等方向,能够解决不能制备出5000MPa级金刚线等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

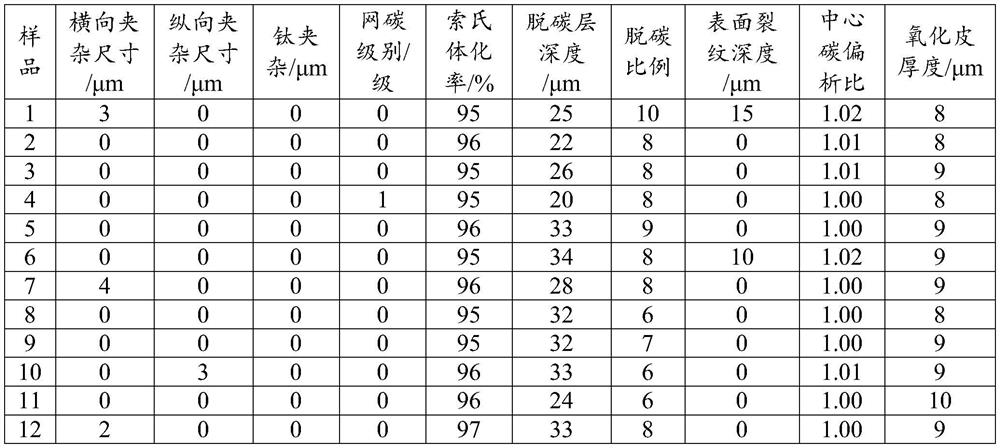

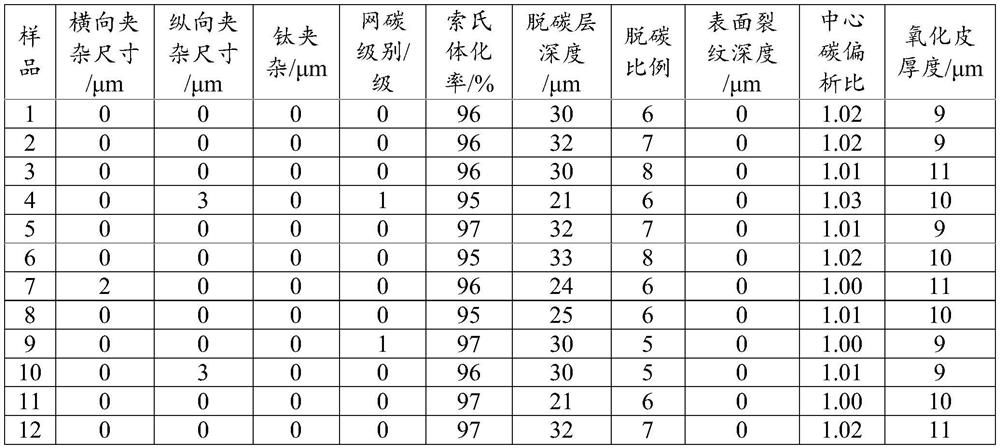

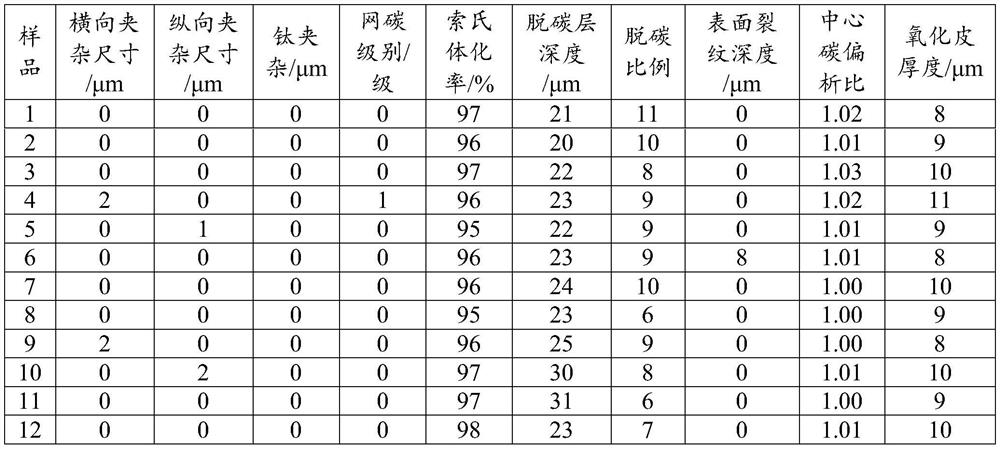

Examples

no. 1 approach

[0050] This embodiment provides a wire rod for deep drawing, especially a wire rod for drawing 5000MPa class diamond wire. Of course, it can be understood that the wire rod can be used to draw a 5000MPa diamond wire busbar, but it is not limited thereto, for example, it can also be used to draw other steel wire products according to the actual production needs of the enterprise.

[0051] The chemical composition of the wire rod includes: C: 1.01-1.10%, Si: 0.15-0.40%, Mn: 0.30-0.60%, Cr: 0.01-0.40%, and B: 0.0005-0.0020% and V : 0.01~0.09% any one or both of the two; the rest is Fe and unavoidable impurities, of which impurities include Al≤0.003%, Ti≤0.0008%, S≤0.005%, P≤0.008%, O≤ 0.0010% and N≤0.0020%.

[0052] The core idea of the design of the chemical composition of the wire rod in the present invention is to increase the content of pearlite strengthening elements, especially the content of C element, while ensuring controllable structure and avoiding the formation of ...

no. 2 approach

[0107] This embodiment also provides a wire rod for deep drawing, especially a wire rod for drawing 5000MPa grade diamond wire, and a production method of the wire rod. The difference between this embodiment and the foregoing first embodiment lies only in the steel ingot remelting process in the production method, and other technologies are the same as the foregoing first embodiment. In the following, only the differences between this embodiment and the aforementioned first embodiment will be introduced, and the rest of the same parts will not be repeated.

[0108] In this embodiment, the process (2) steel ingot remelting process of the production method is specifically as follows.

[0109] In the steel ingot remelting process, the steel ingot is processed by vacuum self-consumption remelting, and the remelting speed is 3.0-3.5kg / min to obtain a remelted ingot. The chemical composition of the remelted ingot is C, Si, Mn, Cr, And either or both of B and V, the rest are Fe and ...

no. 3 approach

[0115] This embodiment also provides a wire rod for deep drawing, especially a wire rod for drawing 5000MPa grade diamond wire, and a production method of the wire rod. The difference between this embodiment and the foregoing first embodiment lies only in the steel ingot remelting process in the production method, and other technologies are the same as the foregoing first embodiment. In the following, only the differences between this embodiment and the aforementioned first embodiment will be introduced, and the rest of the same parts will not be repeated.

[0116] In this embodiment, the process (2) steel ingot remelting process of the production method is specifically as follows.

[0117] In the steel ingot remelting process, the steel ingot obtained in the vacuum smelting process is firstly subjected to electroslag remelting treatment under a protective atmosphere; The melting speed is 3.0-3.5kg / min, and the remelted ingot is obtained. The chemical composition of the remel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| section shrinkage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com