Pitting-resistant multi-component precipitation-hardening stainless steel and heat treatment process thereof

A technology of precipitation hardening and stainless steel, which is applied in the field of iron and steel materials, can solve the problems of urgent improvement, unclear strengthening mechanism of alloying elements, complex composition, etc., and achieve the effect of improving age hardening performance, realizing solid solution and uniform distribution, and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

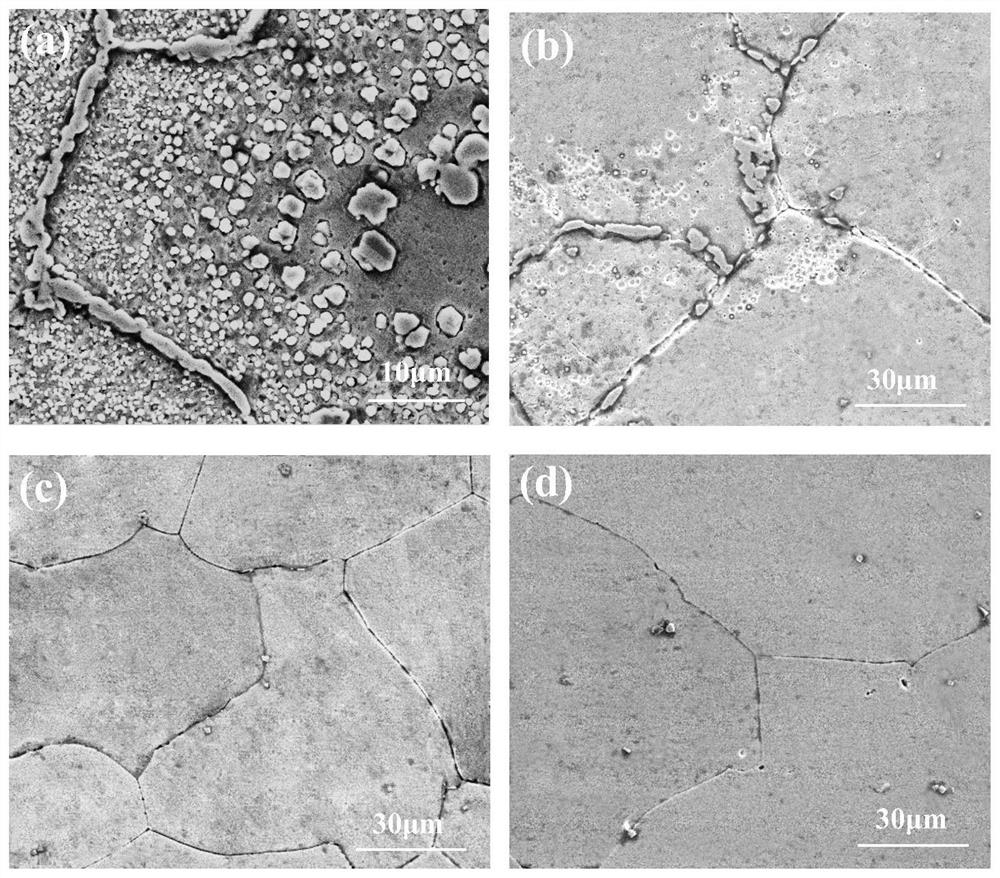

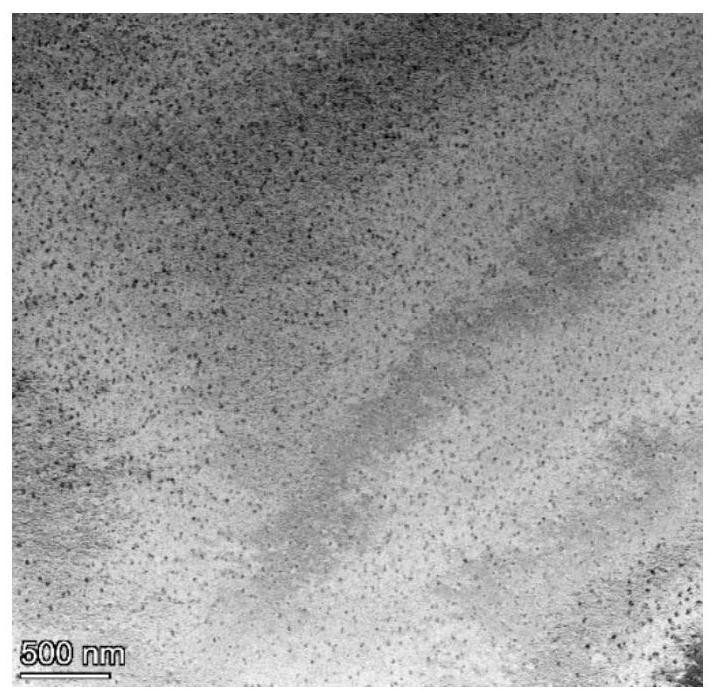

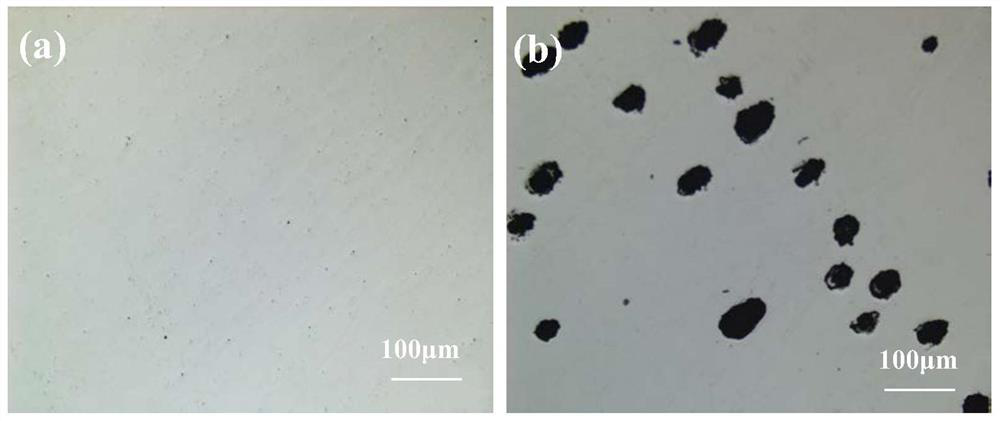

[0025] A heat treatment process for pitting-resistant precipitation-hardening stainless steel, the molar percentage of the composition of the precipitation-hardening stainless steel is Fe 60 Cr 18 Cu 3 (MnCoNiMoAlTi) 19 , its mass percentage content is: Cr: 16.83%, Mn: 3.12%, Cu: 3.43%, Co: 3.35%, Ni: 3.33%, Mo: 5.45%, Al: 1.53%, Ti: 2.72%, and the balance is Fe and unavoidable impurity elements. The purity of the alloying elements used to prepare this composition is ≥99%, and the oxide skin on the surface of the raw metal is removed by mechanical grinding, and then weighed according to the mass percentage of the composition designed in this example, using an electronic balance with an induction capacity of 0.1mg Get the raw material, the total weight of the raw material is about 30g. Subsequently, put the configured raw materials in the copper crucible of the WK non-consumable vacuum electric arc furnace developed by Shenyang Vacuum Technology Research Institute, and evac...

Embodiment 2

[0032] A heat treatment process for pitting-resistant precipitation-hardening stainless steel. This embodiment provides optimized precipitation-hardening stainless steel components. On the basis of the components in Example 1, No. 2 and No. 3 reduce Mn and Cu elements and increase Al and Ti elements. Keep the content of other alloying elements constant. In order to compare the joint precipitation strengthening effect of Al and Ti, the No. 4 and No. 5 components with Ti element or Al element alone were designed for comparison. Further reduce the content of expensive metals Co, Ni, and Mo elements, increase the content of Al, Ti elements to design the No. 6 component, and on this basis, remove the Mn element to adjust the Al, Ti element content to design the No. 7 component. The purity of the selected alloy element raw materials is ≥99%, and the melting preparation method is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com