Thermoformed part with excellent paint film adhesion and method of manufacturing the same

A paint film adhesion and manufacturing method technology, which is applied in the field of thermoforming materials and its manufacturing, can solve the problems of unstable stamping product quality, product appearance and color, easy to change, and change, so as to achieve good paintability and good paint film Adhesion, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

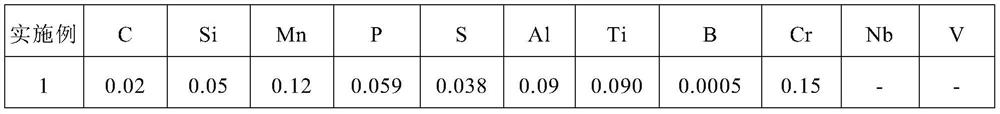

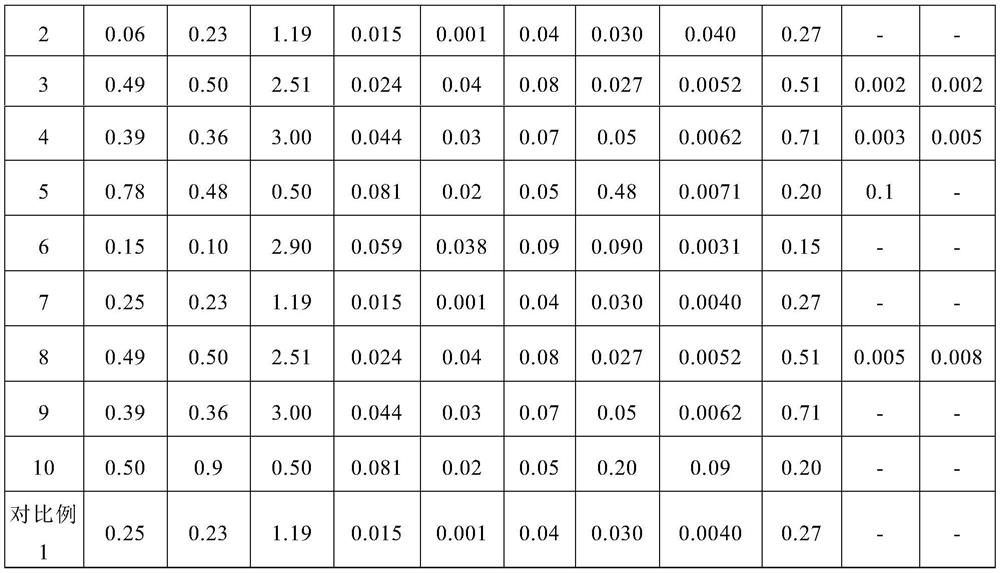

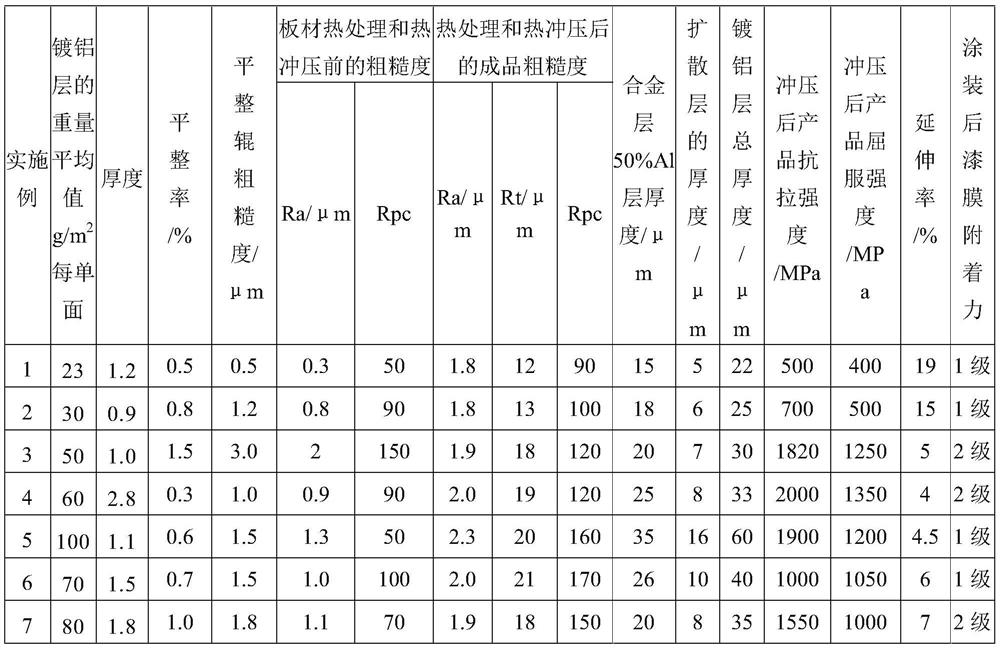

Embodiment 1-10 and comparative example 1

[0060] Thermoformed parts with excellent paint film adhesion of Examples 1-10 were prepared using the following steps:

[0061] (1) Immerse the substrate in an aluminum plating solution to obtain a plate with an aluminum plating layer on the surface.

[0062] (2) Flattening: Use a flattening roller with a roughness Ra of 0.5 to 3.0 μm to flatten the plate, and control the flatness rate to be less than or equal to 2.0%, so that the thermal emissivity of the surface of the plate is 0.1 to 0.8, and the surface roughness of the plate Ra is 0.3 ~2.0μm, the surface roughness peak count Rpc of the plate is 30~150.

[0063] (3) Blanking: blanking or cutting the sheet into the desired shape of the part.

[0064] (4) Heat treatment: put the billet into the heating furnace for heating and keep warm, the temperature of the heating furnace is 880-960 ℃, the atmosphere in the heating furnace adopts air or nitrogen, and the residence time of the billet in the heating furnace is 2.5-10min. ...

Embodiment 1

[0068] The 1.2mm aluminum alloy-coated steel sheet was leveled by a leveling roller, and the sheet before heat treatment and hot stamping was obtained with the surface roughness shown in Table 2. The blanks of certain size and shape were formed by laser blanking. The chemical composition quality of the aluminum plating solution The percentage content is Si: 8.5%, Fe: 2.6%, Zn: 15%, Mg: 4%, and the rest is aluminum and inevitable impurities. The time was 5s, the holding pressure was 10MPA, the clamping speed was 50mm / s, the cooling rate was 50°C / s, and the temperature was cooled to 200°C.

Embodiment 2

[0070] The 0.9mm aluminum alloy-coated steel sheet was leveled by a leveling roller to obtain the sheet with the surface roughness shown in Table 2 before heat treatment and hot stamping. The percentage content is Si: 5%, Fe: 2.4%, Zn: 8%, Mg: 8%, and the rest are aluminum and inevitable impurities. 15s, holding pressure 20MPA, clamping speed 150mm / s, cooling rate 150℃ / s, cooling to 50℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com