A kind of water-based metal matte baking paint with high alkali resistance and strong adhesion and its preparation and use method

A water-based, high-resistance technology, used in coatings, anti-corrosion coatings, and devices that apply liquid to surfaces, and can solve problems such as alkali resistance, ultra-low matte, and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the above-mentioned high alkali resistance and strong adhesion water-based metal matte baking varnish comprises the following process steps:

[0060] Add water-based acrylic modified epoxy ester resin, water, dispersant, wetting agent, part of defoamer, naphthalenesulfonic acid catalyst in the dispersion tank by weight percentage, disperse at a medium speed for 15 minutes, and then slowly add titanium dioxide and talc Powder, superfine calcium carbonate, sericite powder, aluminum zinc phosphomolybdate anti-rust pigment, add water to wash the tank wall, disperse at high speed for 20-50 minutes to fineness ≤ 50 microns; then add high methyl ether at medium and low dispersing speed Melamine formaldehyde resin, cosolvent, leveling agent, thickener, alkoxysilane adhesion promoter, matte powder and the rest of defoamer, dispersed at a medium speed for 30 to 45 minutes; after passing the test, filter and pack .

[0061] Further, the speed of medium-s...

Embodiment 1

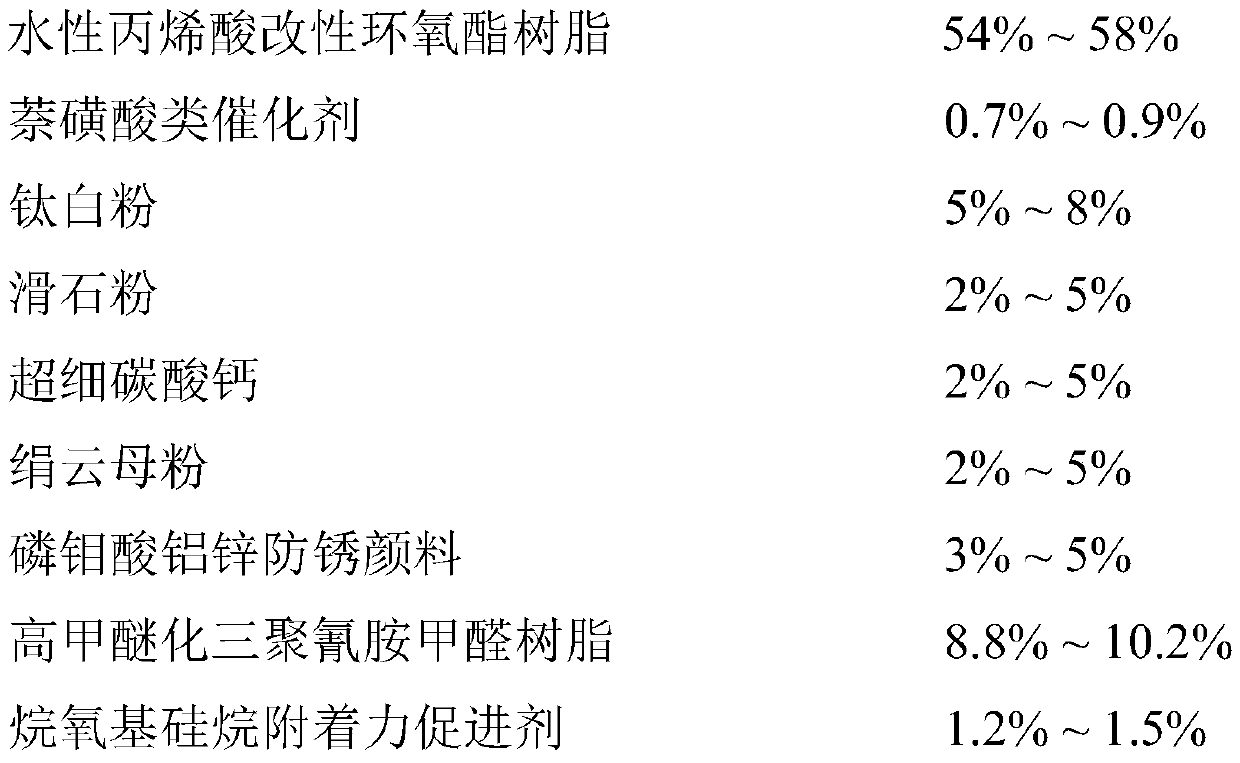

[0065] A water-based metal matte baking varnish with high alkali resistance and strong adhesion, which consists of the following components by weight percentage:

[0066]

[0067]The process steps for preparing the above-mentioned high-alkali-resistant and strong-attached water-based metal matte baking varnish: add water-based acrylic modified epoxy ester resin, water, dispersant, wetting agent, part of defoamer, naphthalenesulfonate in the dispersion tank according to the above weight percentage Acid catalyst, disperse for 15 minutes at a medium speed of 600-800r / min; then slowly add titanium dioxide, talc powder, superfine calcium carbonate, sericite powder, aluminum zinc phosphomolybdate antirust pigment, add water to rinse the cylinder wall, high speed 1000 ~1500r / min disperse for 20~50 minutes until the fineness is ≤50 microns. Then add high methyl etherified melamine formaldehyde resin, co-solvent, leveling agent, thickener, alkoxysilane adhesion promoter, dumb powder...

Embodiment 2

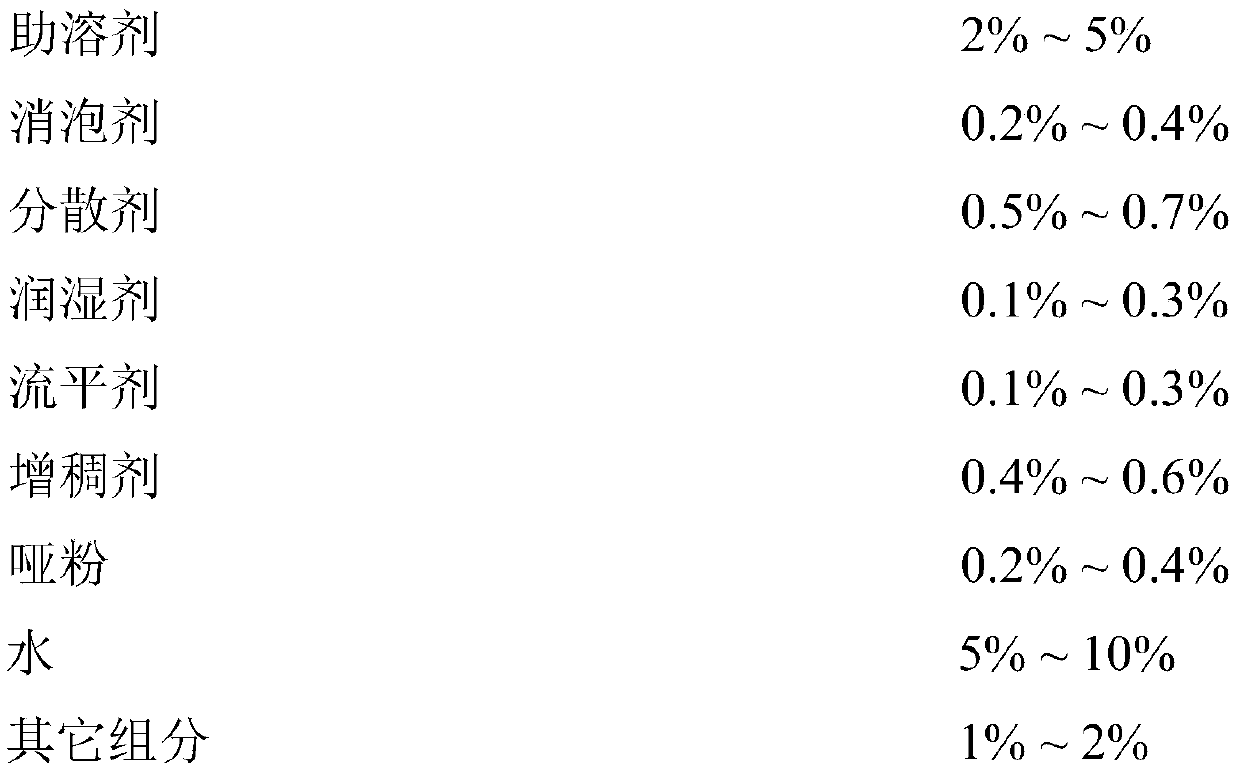

[0071] A water-based metal matte baking varnish with high alkali resistance and strong adhesion, which consists of the following components by weight percentage:

[0072]

[0073] The process steps for preparing the above-mentioned high-alkali-resistant and strong-attached water-based metal matte baking varnish: add water-based acrylic modified epoxy ester resin, water, dispersant, wetting agent, part of defoamer, naphthalenesulfonate in the dispersion tank according to the above weight percentage Acid catalyst, disperse for 15 minutes at a medium speed of 600-800r / min; then slowly add titanium dioxide, talc powder, superfine calcium carbonate, sericite powder, aluminum zinc phosphomolybdate antirust pigment, add water to rinse the cylinder wall, high speed 1000 ~1500r / min disperse for 20~50 minutes until the fineness is ≤50 microns. Then add high methyl etherified melamine formaldehyde resin, co-solvent, leveling agent, thickener, alkoxysilane adhesion promoter, dumb powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com