Preparation and application method of graphene intercalated molybdenum disulfide composite material

A molybdenum disulfide, composite material technology, applied in graphene, molybdenum sulfide, nanotechnology for materials and surface science, etc., can solve the problem that the reversible capacity and cycle stability of the molybdenum disulfide positive electrode are difficult to meet practical application requirements, space Structural instability, poor hydrophilic layer spacing, etc., to achieve the effects of improving hydrophilicity and electronic/ionic conductivity, improving fast charge and discharge capacity, and high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Take 10.5mL of n-butyllithium solution with a concentration of 2.4mol / L, add 15mL of anhydrous pentane to dilute the concentration of n-butyllithium solution to 1mol / L, and evenly disperse 2g of commercial molybdenum disulfide in the above solution , continuously stirred for 5 days under an argon atmosphere, then washed three times with anhydrous pentane, and dried naturally for 2 days under negative pressure to obtain lithium molybdenum sulfide; take 100 mg lithium molybdenum sulfide, and react violently with 15 mL of water under ultrasonic conditions for 3 hours, Obtain a uniform exfoliated molybdenum disulfide dispersion A;

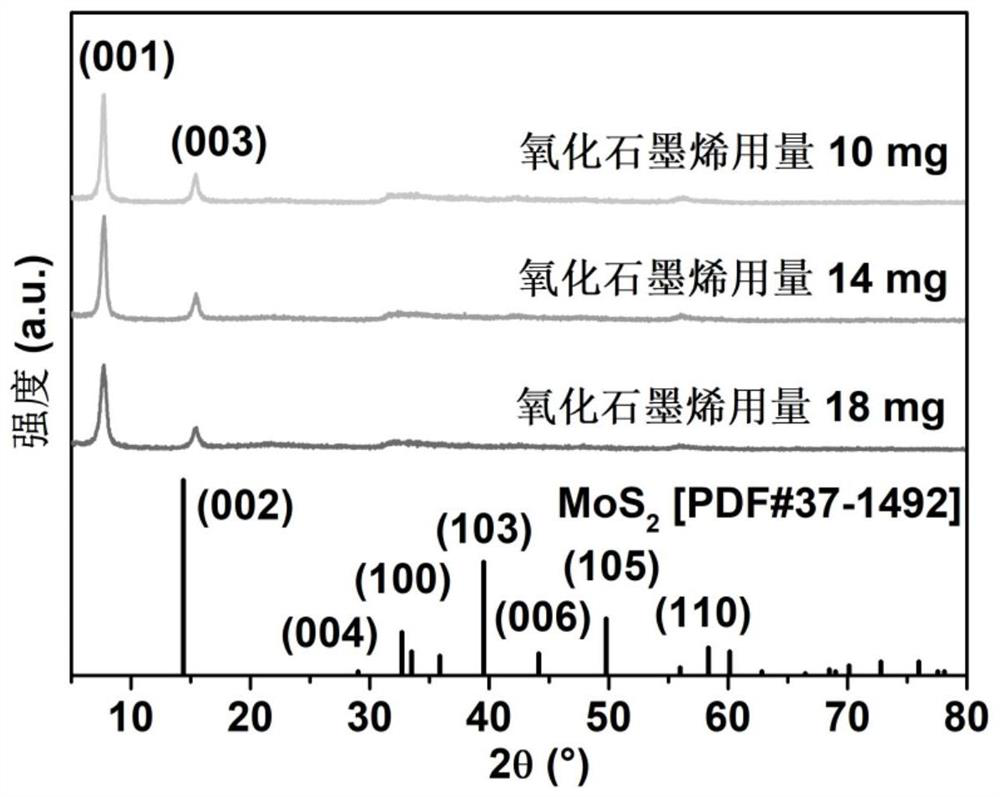

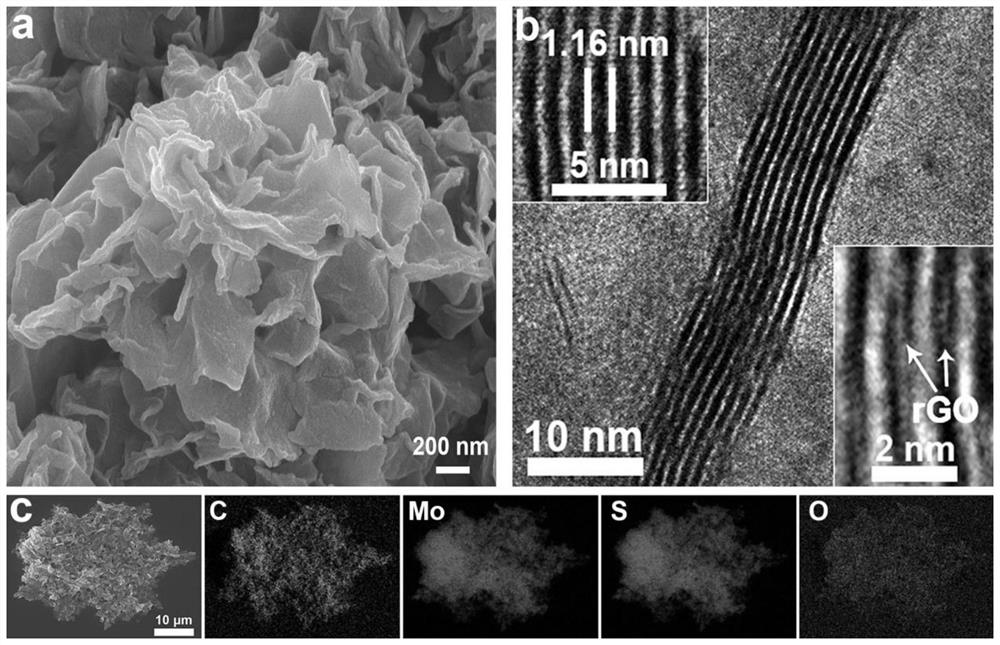

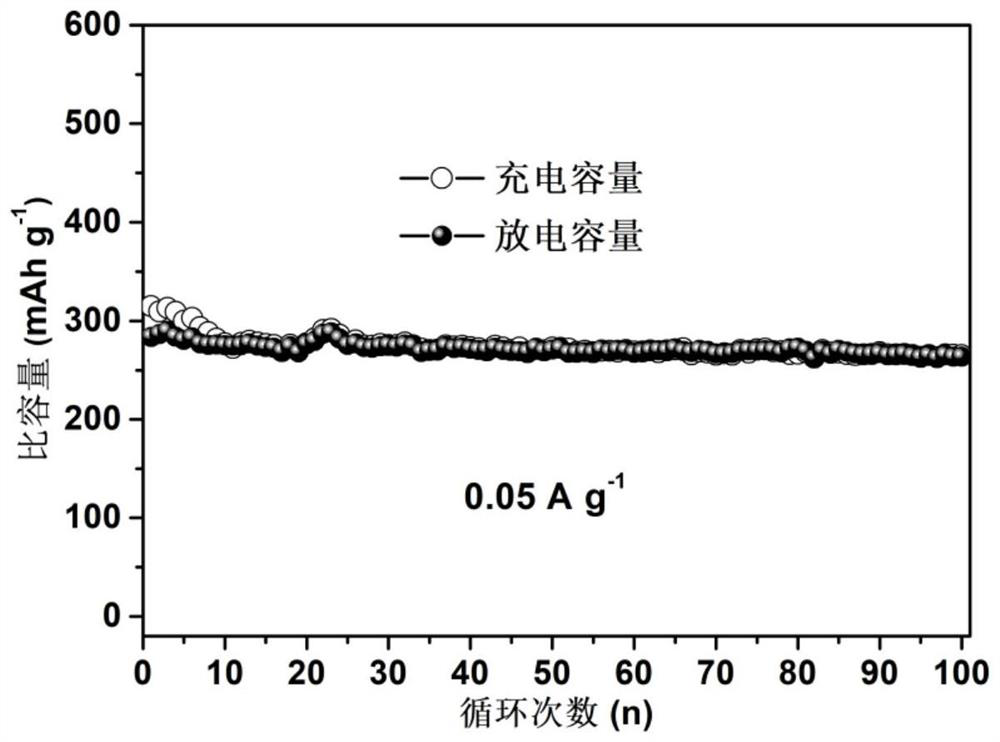

[0024] 2) Dissolve 0.5mmol of cetyltrimethylammonium bromide in 8mL of water evenly, add it to solution A, and keep it under ultrasonic conditions for 2 hours; take 14mg of single-layer graphene oxide and disperse it in 20mL of water, add the above mixed solution Ultrasonic treatment for 2 hours again, so that the exfoliated molybdenum disulf...

Embodiment 2

[0032] 1) Take 10.5mL of n-butyllithium solution with a concentration of 2.4mol / L, add 15mL of anhydrous pentane to dilute the concentration of n-butyllithium solution to 1mol / L, and evenly disperse 2g of commercial molybdenum disulfide in the above solution , continuously stirred for 5 days under an argon atmosphere, then washed three times with anhydrous pentane, and dried naturally for 2 days under negative pressure to obtain lithium molybdenum sulfide; take 100 mg lithium molybdenum sulfide, and react violently with 15 mL of water under ultrasonic conditions for 3 hours, Obtain a uniform exfoliated molybdenum disulfide dispersion A;

[0033] 2) Dissolve 0.5mmol cetyltrimethylammonium bromide uniformly in 8mL water, add it to solution A, and keep it under ultrasonic conditions for 2 hours; take 10mg single-layer graphene oxide and disperse it evenly in 20mL water, add the above mixed solution Ultrasonic treatment for 2 hours again, so that the exfoliated molybdenum disulfid...

Embodiment 3

[0037] 1) Take 10.5mL of n-butyllithium solution with a concentration of 2.4mol / L, add 15mL of anhydrous pentane to dilute the concentration of n-butyllithium solution to 1mol / L, and evenly disperse 2g of commercial molybdenum disulfide in the above solution , continuously stirred for 5 days under an argon atmosphere, then washed three times with anhydrous pentane, and dried naturally for 2 days under negative pressure to obtain lithium molybdenum sulfide; take 100 mg lithium molybdenum sulfide, and react violently with 15 mL of water under ultrasonic conditions for 3 hours, Obtain a uniform exfoliated molybdenum disulfide dispersion A;

[0038] 2) Dissolve 0.5mmol of cetyltrimethylammonium bromide in 8mL of water evenly, add it to solution A, and keep it under ultrasonic conditions for 2 hours; take 18mg of single-layer graphene oxide and disperse it in 20mL of water, add the above mixed solution Ultrasonic treatment for 2 hours again, so that the exfoliated molybdenum disulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com