Preparation method of antibacterial anti-pollution filtering membrane

A filter membrane and anti-pollution technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of complex operation, high cost, and poor controllability of surface properties of antibacterial and anti-pollution filter membranes, and achieve good anti-pollution performance , low price and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Preparation of antibacterial anti-polluting filtration membrane (M1): 10.5 g of polyether sulfone, 4.5 g of polyethylene imine and 15 g of polyethylene glycol (molecular weight 1000) were dissolved in 70 g n, N-dimethylacetamide, at 60 Stir at ° C for 8 h and stand staked. The film formation liquid was applied to a clean glass plate surface with a doctor having a thickness of 250 microns, followed by immersing in water, cured to obtain a positive electro-hydrophilic membrane (M1-a). Putting the positive electro-hydrophil undermeal is placed in aqueous methacrylic acid (2 g / l) aqueous solution, and in the ultraviolet lamp (the main wavelength of the ultraviolet light is 290-400 nm, the power is 100 watts, the film and the ultraviolet lamp distance 5cm) 3 min was obtained by filtration membrane (M1-3); irradiation 4min, resulting in a filter film (M1-4); irradiation 6min, obtained by filter film (M1-6); irradiation 12min, obtained filter film M1-12.

[0034]Characterization metho...

Embodiment 2-23

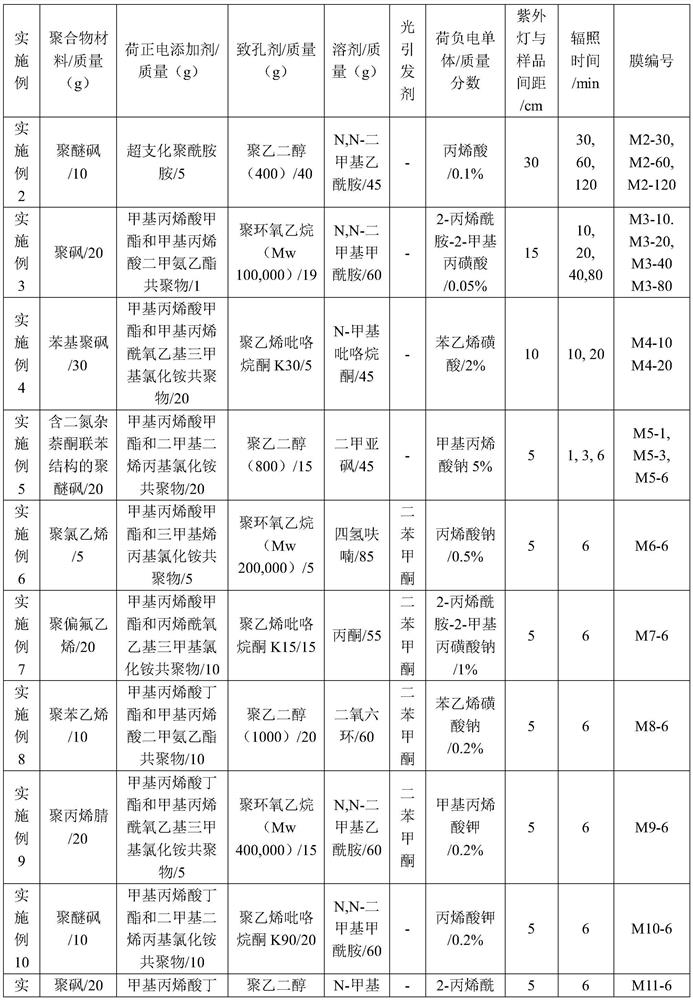

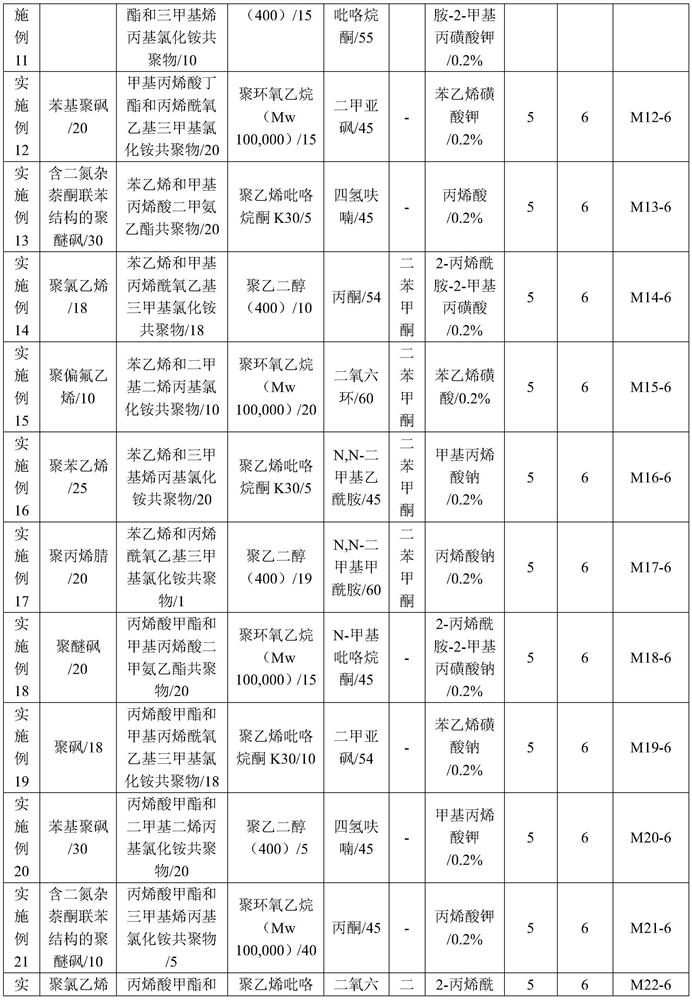

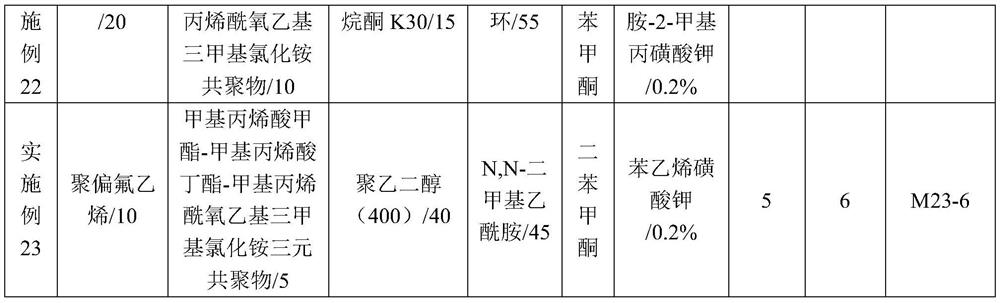

[0039]Preparation conditions As with Table 1, characterization results are shown in Schedule 2.

[0040]The results showed that the load-bearing unit was successfully grafted to the surface of the positive electro-hole under film by ultraviolet irradiation, and as the graft time increased, the pore size of the filter membrane was small, the flux decreased, and the surface chargeability was gradually. Reduce, the flux retention rate is gradually increased, and the bactericidal performance is gradually decreased; when the grafting time is too long, the surface of the surface is bulging, the sterilization performance has dropped sharply, and the anti-pollution performance also shows a decline. For example, M2-120, M3-80 and M-20, due to the too long of UV grafting time, the amount of grafting of the lotion of the load is too high, resulting in a significant lotion, anti-pollution and antibacterial properties.

[0041]1-23 Preparation of conditional data

[0042]

[0043]

[0044]

[0045]Figure 2 Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com