Zirconium-based material surface in-situ ceramization composite treatment method

A composite treatment and ceramization technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem that the quality of ceramization cannot be guaranteed, the surface functional properties that do not fully resist environmental effects, and the hidden danger of pitting corrosion, etc. It can eliminate uncontrollable external pollution factors, eliminate hidden dangers of stress corrosion cracking, and improve corrosion resistance and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

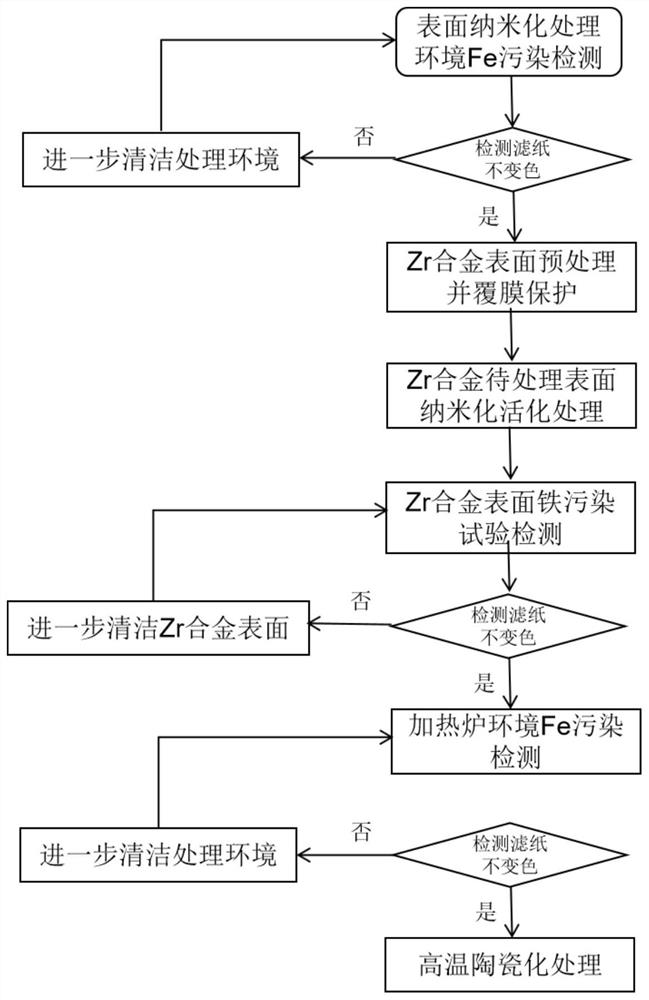

Image

Examples

Embodiment 1

[0040] This embodiment includes the following steps:

[0041] Step 1. Fe pollution detection in the surface nano-treatment environment: put the filter paper glass patch dipped in the detection reagent in the surface nano-treatment environment for 10 hours for Fe pollution detection. The number of measurement points is 20. When dipped in the detection reagent If the filter paper does not change color and the test result is qualified, the Fe pollution in the surface nano-treatment environment is ruled out. When the filter paper dipped in the detection reagent turns orange and the test result is unqualified, the surface nano-treatment environment should be further cleaned until the test result Qualified; the detection reagent is composed of sodium acetate trihydrate, glacial acetic acid, ammonium hydrochloride, o-phenanthroline and distilled water, wherein the concentration of sodium acetate trihydrate is 0.15g / mL, and the concentration of glacial acetic acid is 0.15g / mL, The con...

Embodiment 2

[0055] This embodiment includes the following steps:

[0056] Step 1. Fe pollution detection in the surface nano-treatment environment: put the filter paper glass patch dipped in the detection reagent in the surface nano-treatment environment for 8 hours to detect Fe pollution. The number of measurement points is 30. When dipped in the detection reagent If the filter paper does not change color and the test result is qualified, the Fe pollution in the surface nano-treatment environment is ruled out. When the filter paper dipped in the detection reagent turns yellow, blue-green or reddish-brown, the test result is unqualified, and the surface nano-treatment should be further cleaned. environment, until the test result is qualified; the detection reagent is composed of hydrated sodium phenanthroline disulfonate, hydrochloric acid and distilled water, wherein the concentration of hydrated hydrated sodium phenanthroline disulfonate is 2.5×10 -4 mol / L, the concentration of hydrochl...

Embodiment 3

[0069] This embodiment includes the following steps:

[0070] Step 1. Fe pollution detection in the surface nano-treatment environment: put the filter paper glass patch dipped in the detection reagent in the surface nano-treatment environment for 12 hours for Fe pollution detection. The number of measurement points is 35. When dipped in the detection reagent If the filter paper of the reagent does not change color and the test result is qualified, then the Fe pollution in the surface nano-treatment environment is ruled out. Treat the environment until the test result is qualified; the detection reagent is composed of hydrated sodium phenanthroline disulfonate, hydrochloric acid and distilled water, wherein the concentration of hydrated hydrated sodium phenanthroline disulfonate is 2.5×10 -4 mol / L, the concentration of hydrochloric acid is 0.1×10 -4 mol / L;

[0071] Step 2. Surface pretreatment of zirconium-based materials: After the Zr alloy surface is degreased and degreased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com