High-temperature-resistant and flame-retardant organic silicon sealant for aircraft firewall

A technology of high temperature resistance and firewall, applied in the field of sealant, can solve the problems of incompetent flame retardant performance and the development limit of aerospace vehicles, and achieve the effects of excellent thermal insulation performance, high heat resistance and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

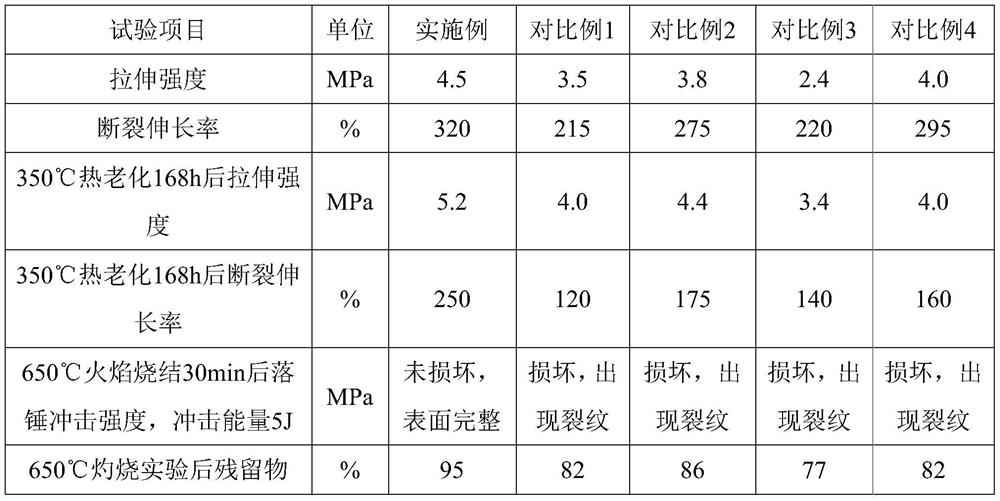

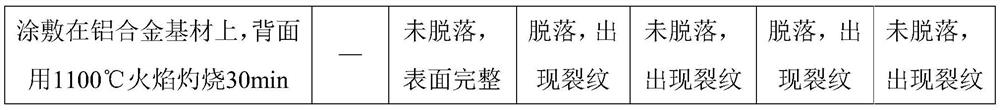

Examples

Embodiment 1

[0021] A ceramizable flame-retardant and high-temperature-resistant sealant, which consists of 10 parts of component A and 1 part of component B in parts by mass;

[0022] Component A is: monophenyl silica gel with 20% phenyl content (viscosity range 8000-20000cP), 40 parts; surface-treated basalt chopped yarn, 1.5cm in length, 10 parts (surface-treated with water-repellent The preparation process of basalt chopped strands is as follows: the basalt continuous long fiber is first drawn through a liquid tank filled with silane coupling agent, and then passed through a 10-meter drying tunnel with hot air at 80°C. The silane coupling agent includes KH550, KH560 and KH570, etc.); 20 parts of lanthanum oxide 800 mesh, 10 parts of cerium oxide 1250 mesh; glass powder 6 μm, 5 parts; surface-treated modified muscovite powder, 20 parts (prepared by surface-treated modified muscovite powder The modification process is as follows: add 100 parts of ordinary muscovite powder into a vacuum k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com