Preparation method of nanowire reinforced silicon nitride foamed ceramic composite silicon dioxide aerogel and product thereof

A technology of composite silica and foamed ceramics, which is applied in ceramic products, other household utensils, applications, etc., can solve the problems of small bonding area of primary particles, poor thermal conductivity, weak bonding force, etc., and achieve uniform distribution of toughening, Increased toughness and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

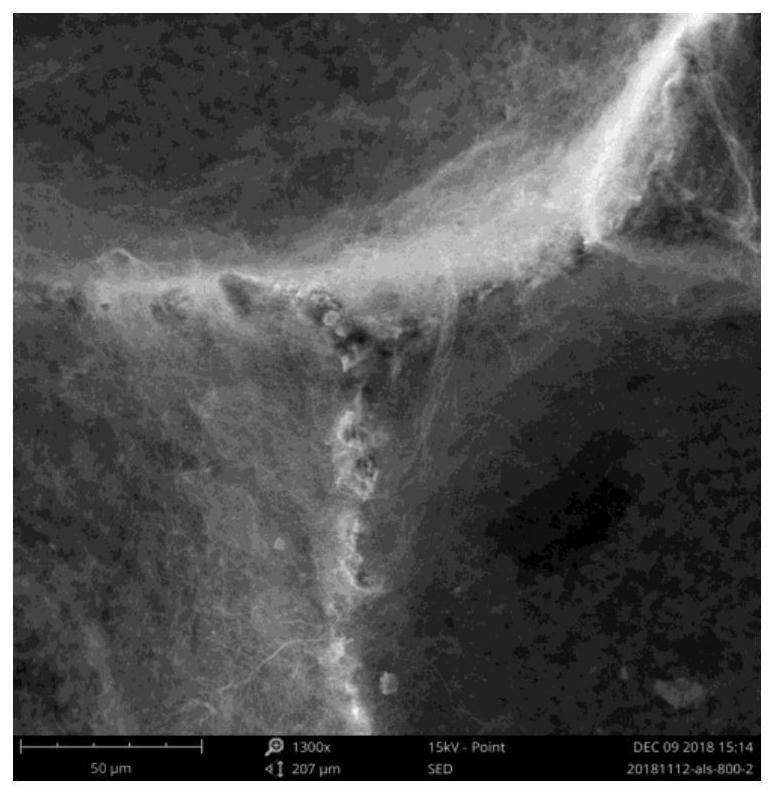

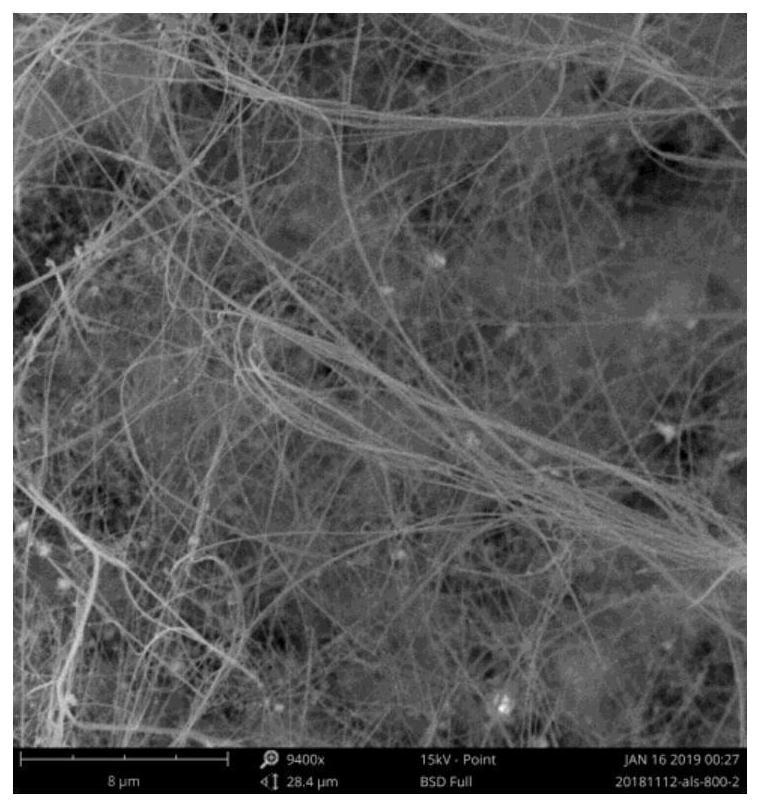

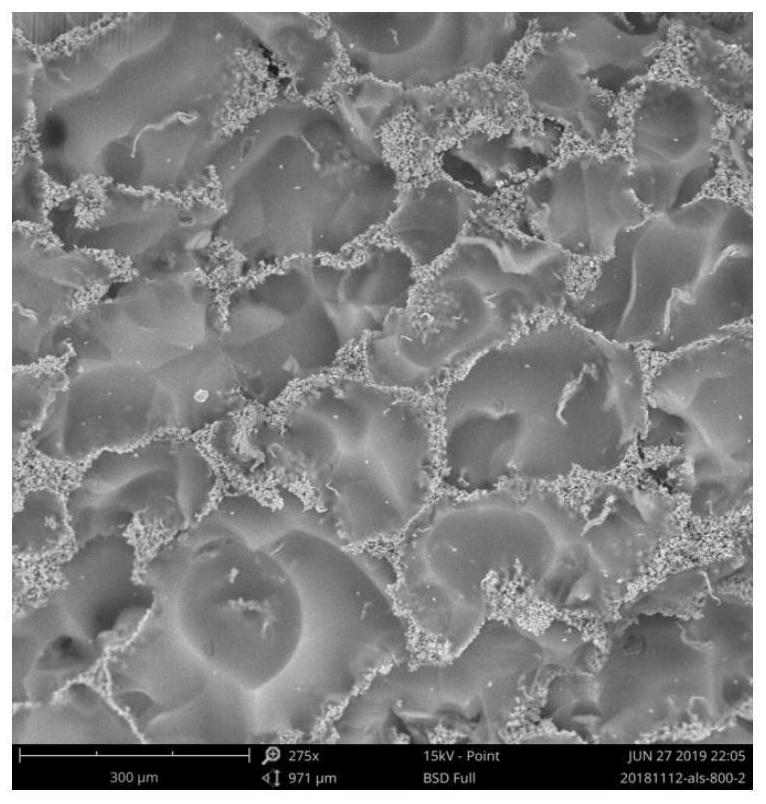

Embodiment 1

[0045] Take by weighing 44% silicon powder, 47% deionized water, 1% aluminum oxide, and 2% yttrium oxide by mass, put the above raw materials into a ball mill, and stir for 20 hours. Then add protein powder with a mass percentage of 6%, and discharge after stirring for 2 hours to obtain a slurry. When forming, pour the mixed slurry into the forming mold. Seal the mold with a plastic wrap and put it into a water bath furnace, solidify it at 80°C for 1 hour, demould it, and dry it in the air for more than 72 hours to obtain a molded body. Put the green body in a crucible and embed silicon nitride powder around it, put it into a nitriding furnace and vacuumize the furnace, and then pass in 0.1MPa nitrogen gas for sintering. The sintering system is as follows: the temperature rise rate is 10°C / min in the range of room temperature (25°C) to 1000°C; the temperature rise rate is 5°C / min from 1000°C to 1200°C; Keep warm for 2 hours, keep warm at 1350°C for 10 hours, and finally cool...

Embodiment 2

[0049] Take by weighing 44% silicon powder, 47% deionized water, 1% aluminum oxide, and 2% yttrium oxide by mass, put the above raw materials into a ball mill, and stir for 20 hours. Then add protein powder with a mass percentage of 6%, and discharge after stirring for 2 hours to obtain a slurry. When forming, pour the mixed slurry into the forming mold. Seal the mold with a plastic wrap and put it into a water bath furnace, solidify it at 80°C for 1 hour, demould it, and dry it in the air for more than 72 hours to obtain a molded body. Put the green body in a crucible and embed silicon nitride powder around it, put it into a nitriding furnace and vacuumize the furnace, and then pass in 0.1MPa nitrogen gas for sintering. The sintering system is as follows: the temperature rise rate is 10°C / min in the range of room temperature (25°C) to 1000°C; the temperature rise rate is 5°C / min from 1000°C to 1200°C; Keep warm for 2 hours, keep warm for 8 hours at 1400°C, and finally cool ...

Embodiment 3

[0053] Take by weighing 44% silicon powder, 47% deionized water, 1% aluminum oxide, and 2% yttrium oxide by mass, put the above raw materials into a ball mill, and stir for 20 hours. Then add protein powder with a mass percentage of 6%, and discharge after stirring for 2 hours to obtain a slurry. When forming, pour the mixed slurry into the forming mold. Seal the mold with a plastic wrap and put it into a water bath furnace, solidify it at 80°C for 1 hour, demould it, and dry it in the air for more than 72 hours to obtain a molded body. Put the green body in a crucible and embed silicon nitride powder around it, put it into a nitriding furnace and vacuumize the furnace, and then pass in 0.1MPa nitrogen gas for sintering. The sintering system is as follows: the temperature rise rate is 10°C / min in the range of room temperature (25°C) to 1000°C; the temperature rise rate is 5°C / min from 1000°C to 1200°C; Keep warm for 2 hours, keep warm for 8 hours at 1450°C, and finally cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com