Telescopic crown retainer based on 3D printing and manufacturing method thereof

A technology of 3D printing and manufacturing methods, which is applied in the fields of additive manufacturing, medical science, filling teeth, etc., and can solve problems such as incompatibility and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention is further described below.

[0065] The method for manufacturing a telescopic crown based on 3D printing disclosed by the present invention comprises the following steps:

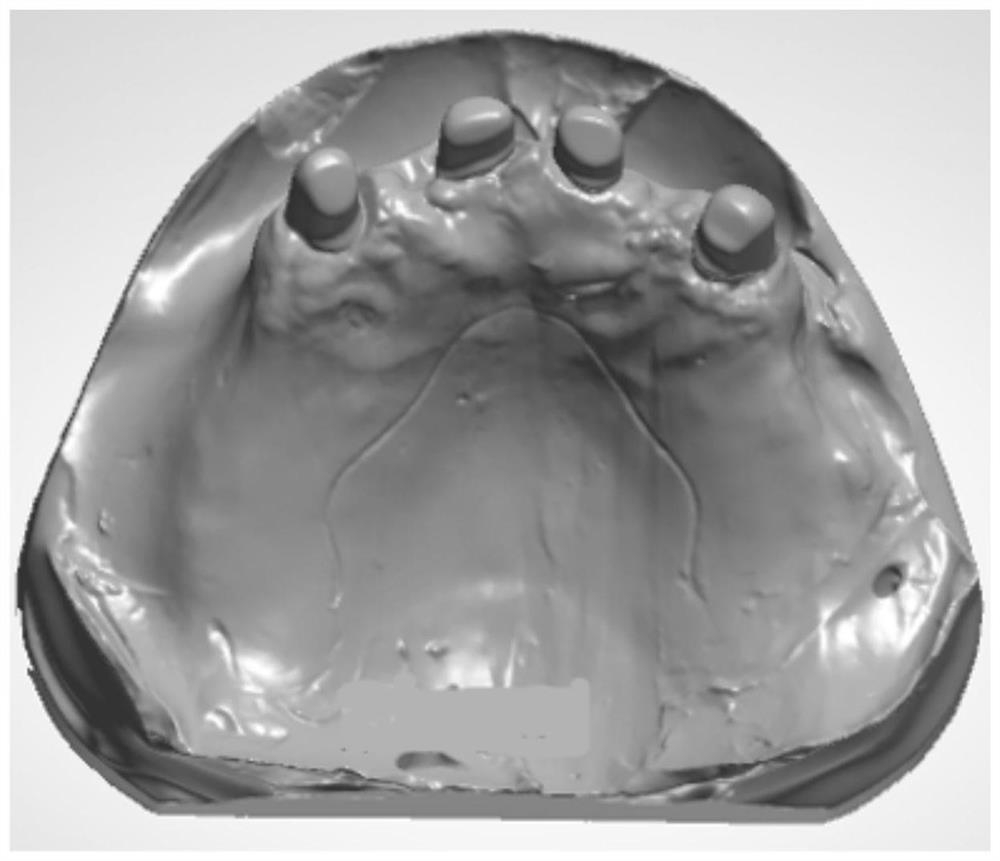

[0066] First-level crown treatment: obtain a three-dimensional digital model including the first-level crown, and determine the common seating path of all first-level crowns. The three-dimensional digital model includes a digital working model, an opposing jaw model, and an occlusal relationship;

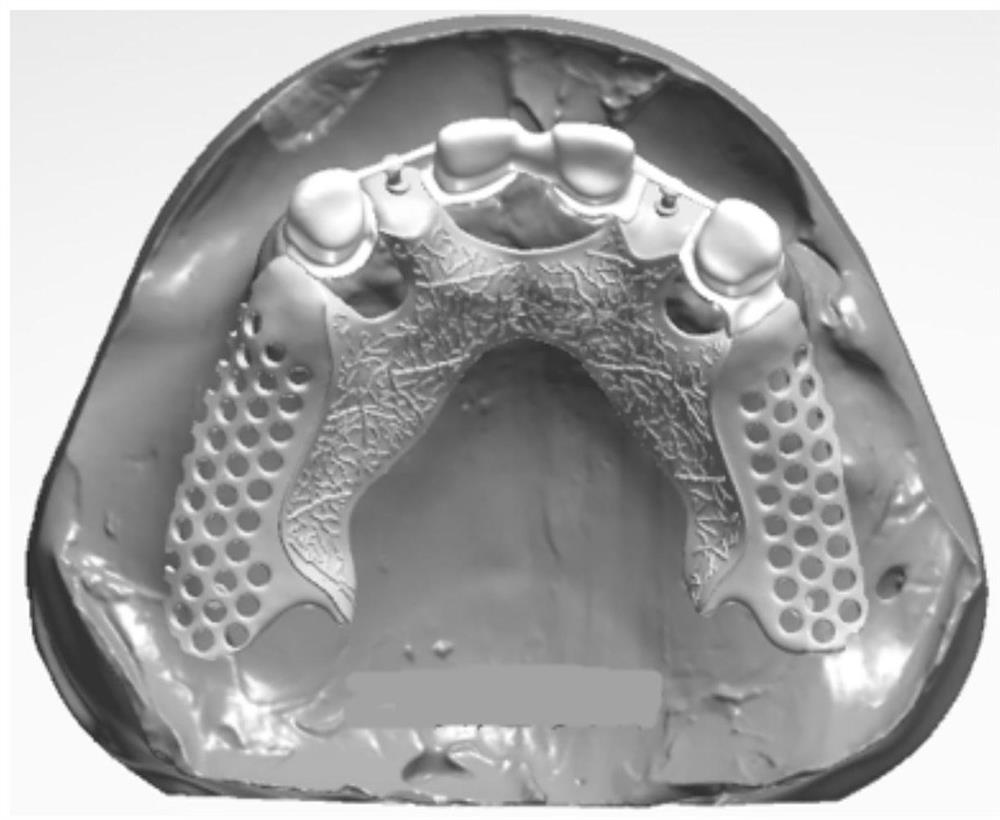

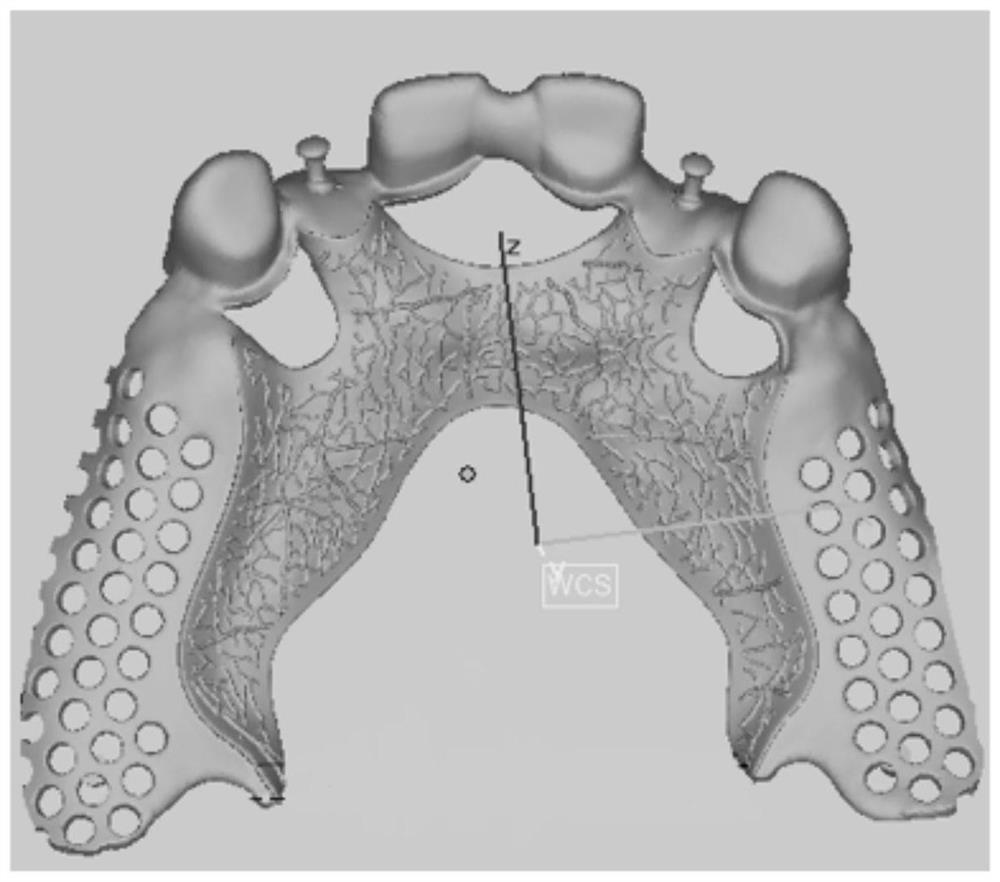

[0067] Design the secondary crown: Edit the shoulder line of the primary crown as the edge line of the secondary crown;

[0068] Generate the gap space between the secondary crown and the primary crown;

[0069] Set the minimum thickness of the secondary crown axial surface, the thickness of the secondary crown edge and the thickness transition angle;

[0070] According to the set secondary crown parameters, a full crown shape with natural tooth shape is generated on the primary cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com