A kind of free-cutting corrosion-resistant steel and preparation method thereof

A technology of corrosion-resistant steel and free-cutting steel, which is applied in the field of steelmaking technology, can solve the problems of not taking into account the free-cutting performance of corrosion-resistant high-nitrogen stainless steel, not taking into account the corrosion resistance of free-cutting steel, and affecting the free-cutting performance of steel, achieving It is beneficial to the cutting performance, alleviates the contradiction that is not easy to coexist, and improves the effect of inclusion morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In a second aspect, the present invention provides a method for preparing the free-cutting corrosion-resistant steel described in the first aspect of the present invention, said method comprising the steps of:

[0047] (1) Mix the free-cutting steel (such as free-cutting nib steel), ferrochrome mixture and slag evenly to obtain steel material; the free-cutting steel contains the following components in mass percentage: C, 0.02%~0.04 % (such as 0.02%, 0.03% or 0.04%); Si, 0.05%~0.15% (such as 0.05%, 0.08%, 0.1%, 0.12% or 0.15%); Mn, 1.4%~1.6% (such as 1.4%, 1.5% or 1.6%); S, 0.32% to 0.38% (such as 0.32%, 0.35% or 0.38%); P, 0.03% to 0.06% (such as 0.03%, 0.04%, 0.05% or 0.06%); Mo, 2%~2.2% (such as 2%, 2.1% or 2.2%); the balance is Fe and unavoidable impurities; in the present invention, the mass percentage of Fe in the free-cutting steel can be, for example, 95% ~96%, the mass percentage of the inevitable impurities in the free-cutting steel is less than 1%; in the pr...

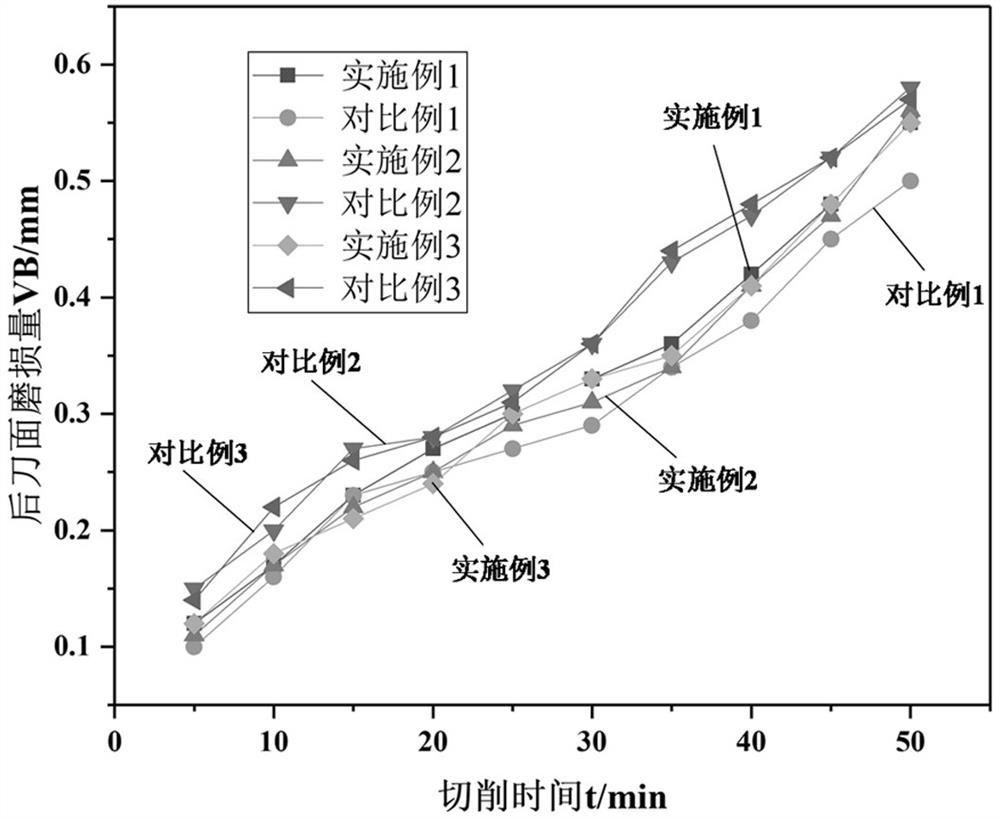

Embodiment 1

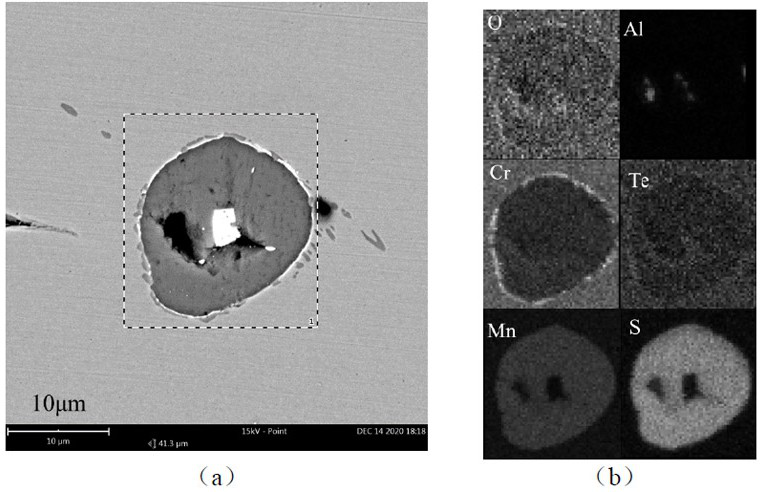

[0069]In this example, the prepared free-cutting corrosion-resistant steel contains the following components in terms of mass percentage: C, 0.02%; Si, 0.45%; Mn, 1.2%; S, 0.26%; P, 0.02%; Mo, 1.6%; Cr, 19.5%; Ca, 0.05%; Mg, 0.01%; , ω[Te] / ω[S]=0.077.

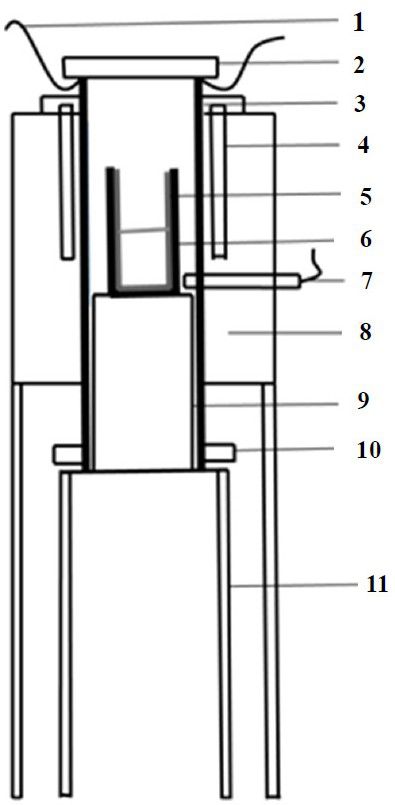

[0070] In this example, a vertical tubular silicon-molybdenum resistance furnace (high-temperature tubular furnace) is used for smelting. The specific operation process is: batching→melting in a high-temperature tubular furnace→adding tellurium→sampling, specifically including the following process:

[0071] Ingredients: Use a cutting machine to cut the finished free-cutting steel wire rod into free-cutting steel blocks with a length of 50mm, weigh 100g of free-cutting steel block samples and put them into a crucible (MgO crucible); weigh 33g of ferrochromium mixture, and weigh 12.5g of slag, adding 12.5g of slag and 33g of ferrochrome mixture into the crucible and mixing to obtain steel; 0.028%; Si, 0.1%; Mn, 1.6%; S, 0.35%;...

Embodiment 2

[0085] In this example, the prepared free-cutting corrosion-resistant steel contains the following components in terms of mass percentage: C, 0.021%; Si, 0.46%; Mn, 1.2%; S, 0.26%; P, 0.02%; Mo, 1.6%; Cr, 19.5%; Ca, 0.05%; Mg, 0.01%; , ω[Te] / ω[S]=0.077.

[0086] In this example, a vertical tubular silicon-molybdenum resistance furnace (high-temperature tubular furnace) is used for smelting. The specific operation process is: batching→melting in a high-temperature tubular furnace→adding tellurium→sampling, specifically including the following process:

[0087] Ingredients: Use a cutting machine to cut the finished free-cutting steel wire rod into free-cutting steel blocks with a length of 50mm, weigh 100g of free-cutting steel block samples and put them into a crucible (MgO crucible); weigh 33g of ferrochromium mixture, and weigh 12.5g of slag, adding 12.5g of slag and 33g of ferrochrome mixture into the crucible and mixing to obtain steel; 0.028%; Si, 0.1%; Mn, 1.6%; S, 0.35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com