A kind of spraying type concrete pavement brick transparent protective agent and preparation method thereof

A technology for concrete pavement and transparent protection, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc. Easy and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

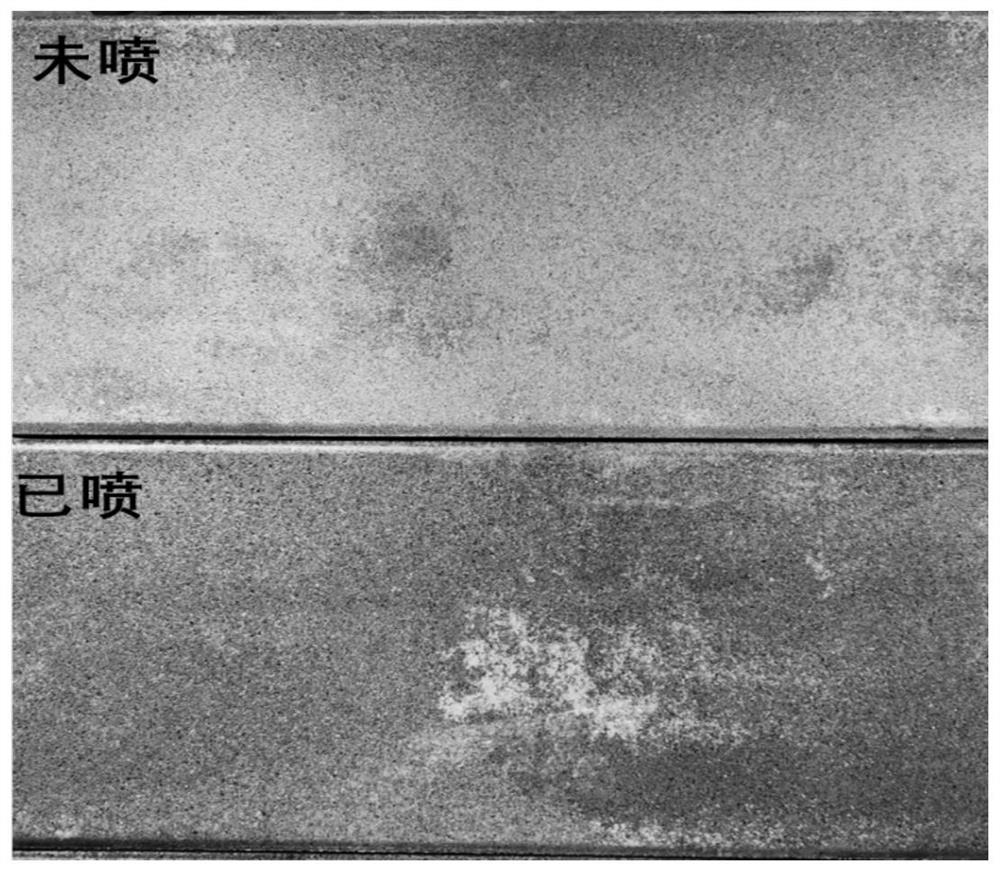

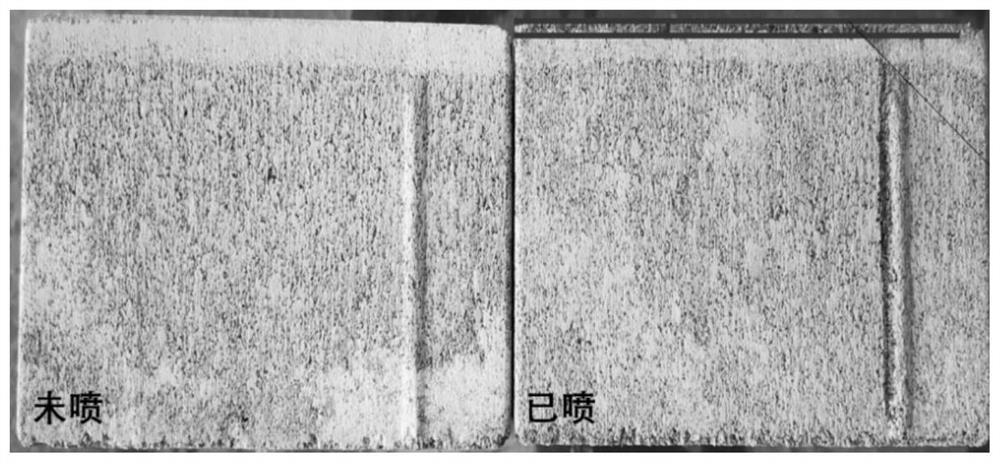

Image

Examples

Embodiment 1

[0054] The protective agent described in this example, the raw materials and dosage used in the preparation are shown in Table 1.1 and Table 1.2 below.

[0055] Preparation raw materials and consumption of protective agent in table 1.1 embodiment 1

[0056]

[0057] Table 1.2 Preparation raw materials and proportioning of epoxy-modified polyurethane prepolymer in Example 1

[0058]

[0059] In this embodiment 1, the preparation method of protecting agent is:

[0060] (1) Mix epoxy-modified polyurethane prepolymer with urethane-grade organic solvent, fully stir and disperse evenly under vacuum conditions, and the stirring rate is 2500-2800r / min;

[0061] (2) Add latent curing agent, silane coupling agent, anti-aging agent, organosilicon defoamer and wetting agent, stir and disperse evenly under vacuum conditions, and make the transparent protective agent for the sprayed concrete pavement bricks, in nitrogen Medium protection storage for later use.

[0062] Among them, th...

Embodiment 2

[0065] The protective agent described in this example, the raw materials and dosage used in the preparation are shown in Table 2.1 and Table 2.2 below.

[0066] Preparation raw materials and consumption of protective agent in table 2.1 embodiment 2

[0067]

[0068] Table 2.2 Preparation raw materials and proportioning of epoxy-modified polyurethane prepolymer in Example 2

[0069]

[0070]

[0071] The preparation method of protective agent and epoxy-modified polyurethane prepolymer is the same as embodiment 1.

Embodiment 3

[0073] The protective agent described in this example, the raw materials and dosage used in the preparation are shown in Table 3.1 and Table 3.2 below.

[0074] Preparation raw materials and consumption of protective agent in table 3.1 embodiment 3

[0075]

[0076] Table 3.2 Preparation raw materials and proportioning of epoxy-modified polyurethane prepolymer in Example 3

[0077]

[0078] The preparation method of protective agent and epoxy-modified polyurethane prepolymer is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com