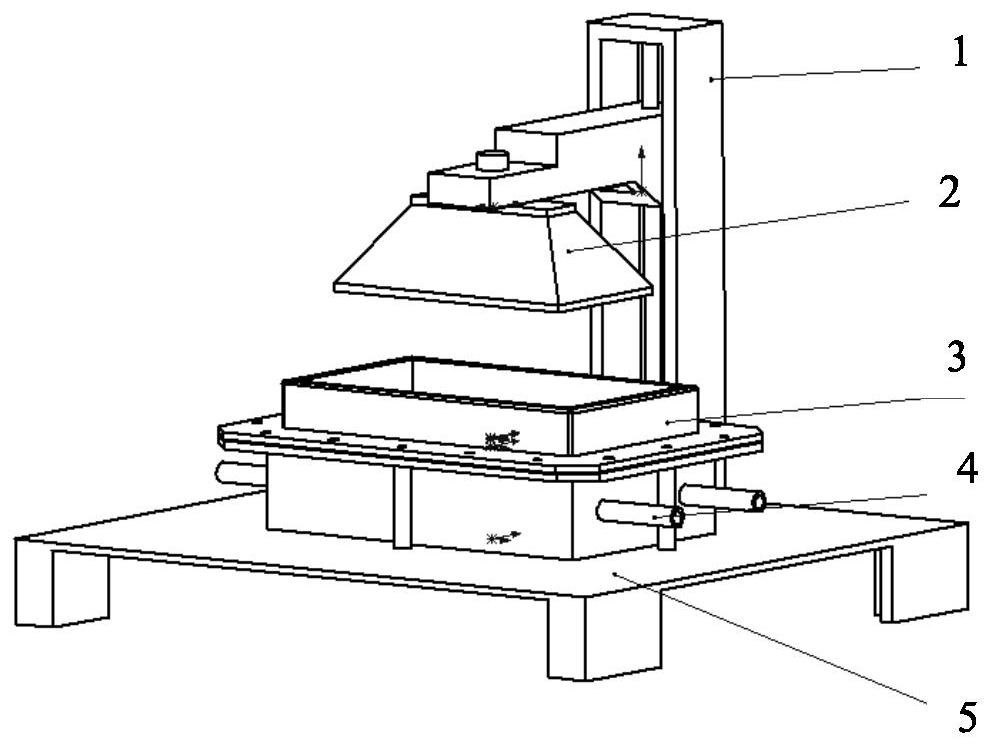

A composite transparent film, its preparation method and continuous light curing 3D printing ceramic method based thereon

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of decreased light source penetration, affecting light transmittance, affecting printing quality, etc., to reduce temperature, improve printing accuracy, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

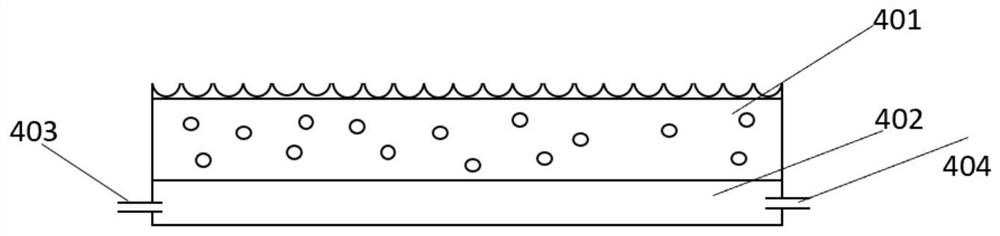

[0057] ① Take spherical SiO with a particle size of 200 nm 2 Granules with Dow Corning PDMS Master Mix, SiO 2 The mass ratio is 20%, and manual stirring is carried out at 200r / min for 2min;

[0058] ②Put the above mixed solution into Songneng DL-3150 ultrasonic cleaning machine and mix for 15min;

[0059] ③ After standing to cool, add PDMS curing agent, the mass ratio of curing agent and PDMS premix is 1 / 10, and stir manually at 200r / min for 3min;

[0060] ④Stand at 4℃ for 24h until there are no bubbles at all;

[0061] ⑤Using Jingyan CNC3040 CNC engraving machine to print the mixed solution into a film with the base plate heating at 90°C, the air pressure of 35Kpa, and 320km / h;

[0062] ⑥ Put the printed film in a drying box and heat it at 90°C for 2h;

[0063] ⑦The fully cured SiO 2 / PDMS hybrid film immersion filled with SiO 2 Suspension container in which SiO 2 The particle size is 3 μm, and the pulling machine is used to pull up vertically at a uniform speed of 2...

Embodiment 2

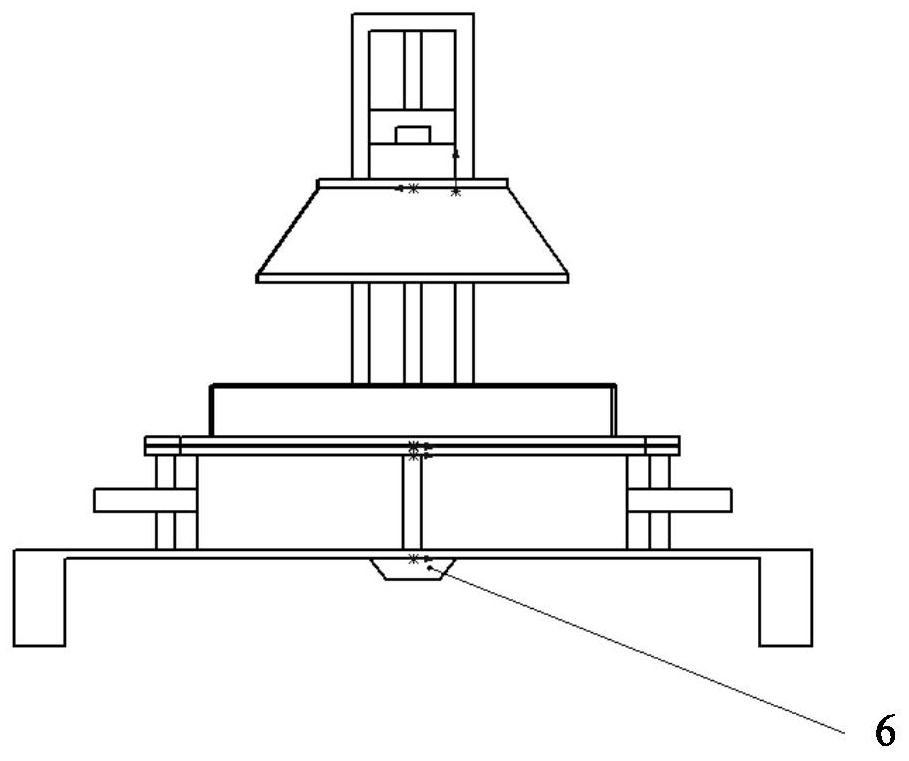

[0070] ①Pour 30vol% ZrO into the storage tank 2 ceramic paste;

[0071] ②Control the bottom of the printing platform to stop 20μm above the composite film;

[0072] ③Introduce cooling oxygen;

[0073] ④Turn on the light source so that the pre-processed image is projected on the composite film;

[0074] ⑤After 10s, control the printing platform to move up at a constant speed of 200mm / h, and at the same time, the projected image is transformed accordingly;

[0075] ⑥ After printing, turn off the light source, pause the printing platform, and stop the circulation of cooling oxygen;

[0076] ⑦Remove the printed ceramic blank and wash off the micro-cured slurry residue with alcohol;

[0077] ⑧Using a UV curing lamp to perform secondary curing on the printed parts, and finally obtain the required ceramic printing blanks;

[0078] ⑨ The required ceramic parts can be obtained after sintering according to the corresponding sintering process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com