Gallium polar surface gallium nitride material and homoepitaxial growth method

A technology of gallium nitride and gallium polarity, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as changing growth temperature and switching air flow, reducing device breakdown voltage, and rough surface morphology of materials. Achieve the effects of reducing material dislocation density, increasing device breakdown voltage, and improving surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

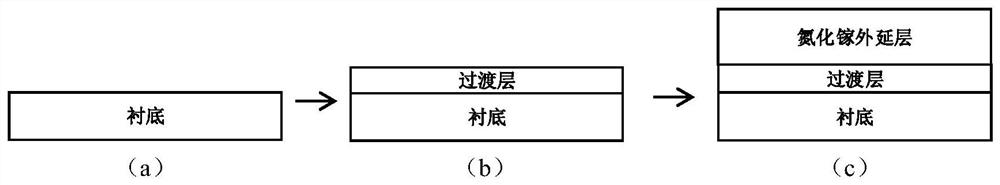

[0031] Example 1, the fabrication substrate is gallium polar c-plane gallium nitride single crystal, and the transition layer is In 0.17 al 0.83 N, the epitaxial layer is gallium nitride material on the gallium polar surface of gallium nitride.

[0032] In step 1, a gallium polar c-plane gallium nitride single crystal is selected as the substrate, such as image 3 (a).

[0033] Step 2, epitaxy In 0.17 al 0.83 N transition layers, such as image 3 (b).

[0034] Place the substrate substrate in the reaction chamber, set the temperature at 660°C, the flow rate of nitrogen gas at 2.3 sccm, and the equilibrium vapor pressure of indium beam at 1.4×10 -7 Torr, the equilibrium vapor pressure of an aluminum beam is 1.5×10 -7 Torr, nitrogen RF source power of 375W process conditions, using molecular beam epitaxy technology, deposited In with a thickness of 10nm on a gallium polar c-plane gallium nitride single crystal substrate 0.17 al 0.83 N transition layer.

[0035] Step 3,...

Embodiment 2

[0037] Example 2, the fabrication substrate is gallium polar c-plane gallium nitride single crystal, and the transition layer is Sc with a thickness of 5nm 0.18 al 0.82 N, the epitaxial layer is gallium nitride material on the gallium polar surface of gallium nitride.

[0038] Step 1, choose gallium polar c-plane gallium nitride single crystal as the substrate, such as image 3 (a).

[0039] Step 2, epitaxial Sc 0.18 al 0.82 N transition layers, such as image 3 (b).

[0040] Place the substrate in the reaction chamber, set the temperature at 680°C, nitrogen flow at 2.3sccm, scandium beam equilibrium vapor pressure at 1.8×10 -8 Torr, the equilibrium vapor pressure of an aluminum beam is 1.4×10 -7 Torr, the nitrogen RF source power is 375W, and the molecular beam epitaxy technology is used to deposit Sc with a thickness of 5nm on the gallium polar c-plane gallium nitride single crystal substrate. 0.18 al 0.82 N transition layer.

[0041] Step 3, using molecular beam e...

Embodiment 3

[0043] Example 3, the fabrication substrate is gallium polar c-plane gallium nitride single crystal, and the transition layer is Y0.11 Al 0.89 N, the epitaxial layer is gallium nitride material on the gallium polar surface of gallium nitride.

[0044] In step A, gallium polar c-plane gallium nitride single crystal is selected as the substrate, such as image 3 (a).

[0045] Step B, epitaxial Y 0.11 Al 0.89 N transition layers, such as image 3 (b).

[0046] The substrate substrate is placed in the reaction chamber, using molecular beam epitaxy technology, at a temperature of 700 ° C, a nitrogen flow rate of 2.3 sccm, and an yttrium beam equilibrium vapor pressure of 1.5×10 -8 Torr, aluminum beam equilibrium vapor pressure is 1.8×10 -7 Torr, under the process conditions of nitrogen RF source power of 375W, Y with a thickness of 1nm was grown on a gallium polar c-plane gallium nitride single crystal substrate 0.11 Al 0.89 N transition layer.

[0047] Step C, growing a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com